Well-designed Forged Steel Ball Valve - 3 Piece Welded Ball Valve – Newsway

Well-designed Forged Steel Ball Valve - 3 Piece Welded Ball Valve – Newsway Detail:

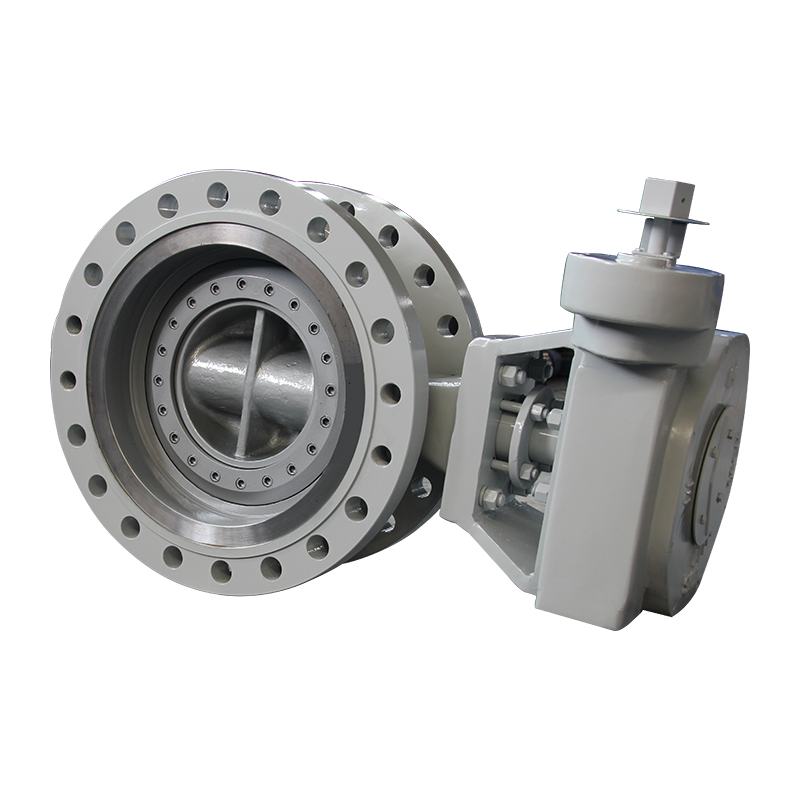

3pcs Welded Ball Valve

Key works: welded, ball, valve, 3pcs, cf8, cf8m, cf3, cf3m, 150lb

PRODUCT RANGE:

Sizes: NPS 1/4 to NPS 4

Pressure Range: Class 150 to Class 2500

Flange Connection: RF, FF, RTJ

MATERIALS:

Casting: (A216 WCB, A351 CF3, CF8, CF3M, CF8M, A995 4A, 5A, A352 LCB, LCC, LC2) Monel, Inconel, Hastelloy, UB6

Forged (A105, A182 F304, F304L, F316, F316L, F51, F53, A350 LF2, LF3, LF5,)

STANDARD

| Design & manufacture | API 6D, ASME B16.34 |

| Face-to-face | ASME B16.34, DIN 3202-M3 |

| End Connection | ASME B1.20.1,BS21,DIN 2999/259,ISO 228/1,JIS B 0203,ISO 7/1 |

| Test & inspection | MSS SP-110,EN 1226 |

| Fire safe design | API 6FA, API 607 |

| Also available per | NACE MR-0175, NACE MR-0103, ISO 15848 |

| Other | PMI, UT, RT, PT, MT |

Design Features:

1.Blow-out Proof Stem

2.Pressure Balance Hole in Ball Slot

3.Lock device

4.Various Thread Standards Available

The 3-piece welded end ball valve can be closed tightly with only a 90-degree rotation and a small torque. The completely equal internal cavity of the valve provides a straight flow channel with little resistance for the medium. The main feature of the ball valve is its compact structure, easy to operate and maintain. The stainless steel ball valve can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil, liquid metal and radioactive media. The valve body of the ball valve can be integral or combined. This type of valve should generally be installed horizontally in the pipeline. Stainless steel ball valve classification: stainless steel pneumatic ball valve, stainless steel electric ball valve, stainless steel manual ball valve. The 3-piece welded stainless steel ball valve is made of 304,316,321 stainless steel ball valves.

1. Open and close without friction. This function completely solves the problem of traditional valves affecting the sealing due to mutual friction between the sealing surfaces

2. Top loading structure. The valves installed in the pipeline can be directly inspected and repaired online, which can effectively reduce device shutdown and reduce costs.

3. Single valve seat design. Eliminates the problem that the medium in the valve cavity affects the safety of use due to abnormal pressure increase.

4. Low torque design. The valve stem with special structure design can be opened and closed easily with only a small handwheel valve.

5. Wedge-shaped sealing structure. The valve relies on the mechanical force provided by the valve stem to press the ball wedge onto the valve seat to seal, so that the sealing performance of the valve is not affected by the change of pipeline pressure, and the sealing performance is reliably guaranteed under various working conditions.

6. Self-cleaning structure of the sealing surface. When the ball is tilted away from the valve seat, the fluid in the pipeline will pass through the sealing surface of the ball uniformly at 360°, which not only eliminates the local washing of the valve seat by the high-speed fluid, but also washes away the accumulation on the sealing surface to achieve the purpose of self-cleaning .

Product detail pictures:

Related Product Guide:

Cooperation

Bear "Customer first, Excellent first" in mind, we operate closely with our customers and supply them with efficient and expert services for Well-designed Forged Steel Ball Valve - 3 Piece Welded Ball Valve – Newsway , The product will supply to all over the world, such as: Bolivia, Portland, Mozambique, Due to the changing trends in this field, we involve ourselves into products trade with dedicated efforts and managerial excellence. We maintain timely delivery schedules, innovative designs, quality and transparency for our customers. Our moto is to deliver quality products within stipulated time.

Newsway Valves Materials

NSW valve body and trim material can be offered in Forged type and Casting type. Next to stainless and carbon steel material, we also manufacture valves in special materials such as titanium, nickel alloys, HASTELLOY®*, INCOLOY®, MONEL®, Alloy 20, super-duplex, corrosion resistant alloys and urea grade materials.

Available materials

| Tradename | UNS nr. | Werkstoff nr. | Forging | Casting |

| Carbon steel | K30504 | 1.0402 | A105 | A216 WCB |

| Carbon steel | 1.046 | A105N | ||

| Low Temp Carbon steel | K03011 | 1.0508 | A350 LF2 | A352 LCB |

| High Yield steel | K03014 | A694 F60 | ||

| 3 1/2 Nickel steel | K32025 | 1.5639 | A350 LF3 | A352 LC3 |

| 5 Chrome, 1/2 Moly | K41545 | 1.7362 | A182 F5 | A217 C5 |

| 1 1/4 Chrome, 1/2 Moly | K11572 | 1.7733 | A182 F11 | A217 WC6 |

| K11597 | 1.7335 | |||

| 2 1/4 Chrome, 1/2 Moly | K21590 | 1.738 | A182 F22 | A217 WC9 |

| 9 Chrome, 1 Moly | K90941 | 1.7386 | A182 F9 | A217 CW6 |

| X 12 Chrome, 091 Moly | K91560 | 1.4903 | A182 F91 | A217 C12 |

| 13 Chrome | S41000 | A182 F6A | A351 CA15 | |

| 17-4PH | S17400 | 1.4542 | A564 630 | |

| 254 SMo | S31254 | 1.4547 | A182 F44 | A351 CK3MCuN |

| 304 | S30400 | 1.4301 | A182 F304 | A351 CF8 |

| 304L | S30403 | 1.4306 | A182 F304L | A351 CF3 |

| 310S | S31008 | 1.4845 | A182 F310S | A351 CK20 |

| 316 | S31600 | 1.4401 | A182 F316 | A351 CF8M |

| S31600 | 1.4436 | |||

| 316L | S31603 | 1.4404 | A182 F316L | A351 CF3M |

| 316Ti | S31635 | 1.4571 | A182 F316Ti | |

| 317L | S31703 | 1.4438 | A182 F317L | A351CG8M |

| 321 | S32100 | 1.4541 | A182 F321 | |

| 321H | S32109 | 1.4878 | A182 F321H | |

| 347 | S34700 | 1.455 | A182 F347 | A351 CF8C |

| 347H | S34709 | 1.4961 | A182 F347H | |

| 410 | S41000 | 1.4006 | A182 F410 | |

| 904L | N08904 | 1.4539 | A182 F904L | |

| Carpenter 20 | N08020 | 2.466 | B462 N08020 | A351 CN7M |

| Duplex 4462 | S31803 | 1.4462 | A182 F51 | A890 Gr 4A |

| SAF 2507 | S32750 | 1.4469 | A182 F53 | A890 Gr 6A |

| Zeron 100 | S32760 | 1.4501 | A182 F55 | A351 GR CD3MWCuN |

| Ferralium® 255 | S32550 | 1.4507 | A182 F61 | |

| Nicrofer 5923 hMo | N06059 | 2.4605 | B462 N06059 | |

| Nickel 200 | N02200 | 2.4066 | B564 N02200 | |

| Nickel 201 | N02201 | 2.4068 | B564 N02201 | |

| Monel® 400 | N04400 | 2.436 | B564 N04400 | A494 M35-1 |

| Monel® K500 | N05500 | 2.4375 | B865 N05500 | |

| Incoloy® 800 | N08800 | 1.4876 | B564 N08800 | |

| Incoloy® 800H | N08810 | 1.4958 | B564 N08810 | |

| Incoloy® 800HT | N08811 | 1.4959 | B564 N08811 | |

| Incoloy® 825 | N08825 | 2.4858 | B564 N08825 | |

| Inconel® 600 | N06600 | 2.4816 | B564 N06600 | A494 CY40 |

| Inconel® 625 | N06625 | 2.4856 | B564 N06625 | A494 CW 6MC |

| Hastelloy® B2 | N10665 | 2.4617 | B564 N10665 | A494 N 12MV |

| Hastelloy® B3 | N10675 | 2.46 | B564 N10675 | |

| Hastelloy® C22 | N06022 | 2.4602 | B574 N06022 | A494 CX2MW |

| Hastelloy® C276 | N10276 | 2.4819 | B564 N10276 | |

| Hastelloy® C4 | N06455 | 2.461 | B574 N06455 | |

| Titanium GR. 1 | R50250 | 3.7025 | B381 F1 | B367 C1 |

| Titanium GR. 2 | R50400 | 3.7035 | B381 F2 | B367 C2 |

| Titanium GR. 3 | R50550 | 3.7055 | B381 F3 | B367 C3 |

| Titanium GR. 5 | R56400 | 3.7165 | B381 F5 | B367 C5 |

| Titanium GR. 7 | R52400 | 3.7235 | B381 F7 | B367 C7 |

| Titanium GR. 12 | R53400 | 3.7225 | B381 F12 | B367 C12 |

| Zirconium® 702 | R60702 | B493 R60702 | ||

| Zirconium® 705 | R60705 | B493 R60705 |

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!