Triple Offset Butterfly Valve

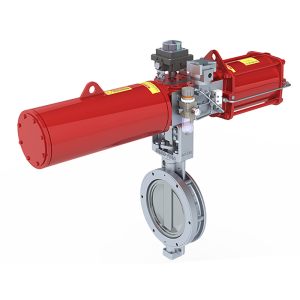

Triple Offset Butterfly Valve Detail:

Triple Offset Butterfly Valve: Comprehensive Product Overview

What is a Triple Offset Butterfly Valve

A triple offset butterfly valve (TOBV) is a high-performance industrial valve designed for precise flow control in demanding applications. Its unique geometry minimizes wear, ensures bubble-tight sealing, and operates efficiently under extreme temperatures and pressures. Unlike conventional butterfly valves, the TOBV employs a triple eccentric design to eliminate friction between the disc and seat during operation, making it ideal for critical services.

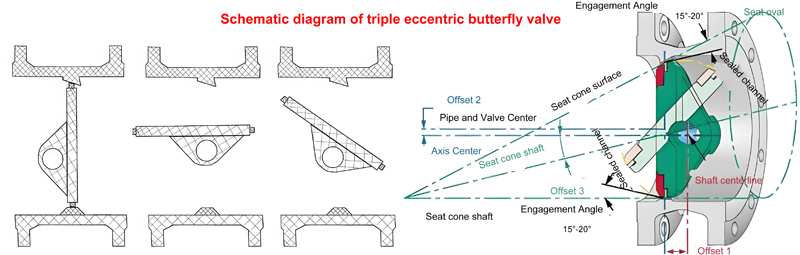

Understanding the "Triple Offset" Design

The term "triple offset" refers to three distinct geometric offsets in the valve’s construction:

1. First Offset: The valve shaft is positioned behind the seat’s centerline, enabling the disc to rotate without contacting the seat.

2. Second Offset: The shaft is offset from the pipeline’s centerline, creating a cam-like motion for smooth operation.

3. Third Offset: The seat surface is angled (conical profile), ensuring a wedging effect that enhances sealing as the valve closes.

This design eliminates sliding friction, reduces wear, and guarantees zero leakage even after prolonged use.

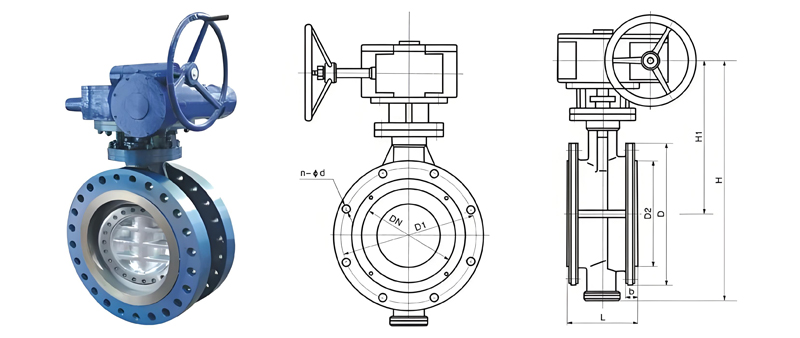

Key Specifications

Valve Sizes

- Standard Range: 2" to 48" (DN50 to DN1200).

- Custom Sizes: Available for specialized industrial requirements.

Pressure Ratings

- ANSI Classes: 150 to 600.

- PN Ratings: PN16 to PN100.

- Suitable for high-pressure systems up to 1,450 psi (100 bar).

Connection Types

- Flanged: ANSI, DIN, or JIS standard flanges.

- Wafer/Lug: Compact design for space-constrained installations.

- Butt-Weld: For permanent, high-integrity piping systems.

Materials

- Body/Trim: Stainless steel (SS316, SS304), duplex steel, carbon steel, Inconel®, Hastelloy®.

- Seat: Resilient metal-to-metal seals or laminated composite materials (e.g., graphite + stainless steel).

- Disc: Often coated with stellite or ceramic for abrasion resistance.

Operating Conditions

- Temperature Range: -196°C to 850°C (-320°F to 1,562°F).

- Media: Compatible with steam, hydrocarbons, corrosive chemicals, and cryogenic fluids.

- Industries: Oil & gas, power generation, chemical processing, LNG, and marine.

Advantages of Triple Offset Butterfly Valves

1. Zero Leakage: Metal-seated design meets ISO 5208 Leakage Class A (bubble-tight).

2. Long Service Life: No friction ensures minimal wear, even after thousands of cycles.

3. Low Maintenance: No regular lubrication or seat replacement required.

4. Versatility: Adaptable to extreme temperatures, pressures, and corrosive media.

Applications

- Oil Refineries: Isolation and regulation of crude oil, gas, and refined products.

- Power Plants: Steam isolation in turbines and boilers.

- Chemical Plants: Handling acids, alkalis, and aggressive fluids.

- Cryogenic Systems: LNG storage and transportation.

Compliance & Certifications

- Standards: API 609, ASME B16.34, ISO 5752.

- Fire-Safe Design: Compliant with API 607/API 6FA for fire-resistant applications.

The triple offset butterfly valve combines precision engineering with robust materials to deliver unmatched reliability in critical industrial processes. Its advanced design addresses the limitations of traditional valves, making it a preferred choice for modern high-performance systems.

Product detail pictures:

Related Product Guide:

Cooperation

We will constantly satisfy our respected customers with our good excellent, superior value and superior assistance due to we're additional experienced and far more hard-working and do it in cost-effective way for Triple Offset Butterfly Valve , The product will supply to all over the world, such as: Vietnam, Croatia, Bahamas, Customer satisfaction is our first goal. Our mission is to pursue the superlative quality, making continual progress. We sincerely welcome you to make progress hand in hand with us, and construct a prosperous future together.

Newsway Valves Materials

NSW valve body and trim material can be offered in Forged type and Casting type. Next to stainless and carbon steel material, we also manufacture valves in special materials such as titanium, nickel alloys, HASTELLOY®*, INCOLOY®, MONEL®, Alloy 20, super-duplex, corrosion resistant alloys and urea grade materials.

Available materials

| Tradename | UNS nr. | Werkstoff nr. | Forging | Casting |

| Carbon steel | K30504 | 1.0402 | A105 | A216 WCB |

| Carbon steel | 1.046 | A105N | ||

| Low Temp Carbon steel | K03011 | 1.0508 | A350 LF2 | A352 LCB |

| High Yield steel | K03014 | A694 F60 | ||

| 3 1/2 Nickel steel | K32025 | 1.5639 | A350 LF3 | A352 LC3 |

| 5 Chrome, 1/2 Moly | K41545 | 1.7362 | A182 F5 | A217 C5 |

| 1 1/4 Chrome, 1/2 Moly | K11572 | 1.7733 | A182 F11 | A217 WC6 |

| K11597 | 1.7335 | |||

| 2 1/4 Chrome, 1/2 Moly | K21590 | 1.738 | A182 F22 | A217 WC9 |

| 9 Chrome, 1 Moly | K90941 | 1.7386 | A182 F9 | A217 CW6 |

| X 12 Chrome, 091 Moly | K91560 | 1.4903 | A182 F91 | A217 C12 |

| 13 Chrome | S41000 | A182 F6A | A351 CA15 | |

| 17-4PH | S17400 | 1.4542 | A564 630 | |

| 254 SMo | S31254 | 1.4547 | A182 F44 | A351 CK3MCuN |

| 304 | S30400 | 1.4301 | A182 F304 | A351 CF8 |

| 304L | S30403 | 1.4306 | A182 F304L | A351 CF3 |

| 310S | S31008 | 1.4845 | A182 F310S | A351 CK20 |

| 316 | S31600 | 1.4401 | A182 F316 | A351 CF8M |

| S31600 | 1.4436 | |||

| 316L | S31603 | 1.4404 | A182 F316L | A351 CF3M |

| 316Ti | S31635 | 1.4571 | A182 F316Ti | |

| 317L | S31703 | 1.4438 | A182 F317L | A351CG8M |

| 321 | S32100 | 1.4541 | A182 F321 | |

| 321H | S32109 | 1.4878 | A182 F321H | |

| 347 | S34700 | 1.455 | A182 F347 | A351 CF8C |

| 347H | S34709 | 1.4961 | A182 F347H | |

| 410 | S41000 | 1.4006 | A182 F410 | |

| 904L | N08904 | 1.4539 | A182 F904L | |

| Carpenter 20 | N08020 | 2.466 | B462 N08020 | A351 CN7M |

| Duplex 4462 | S31803 | 1.4462 | A182 F51 | A890 Gr 4A |

| SAF 2507 | S32750 | 1.4469 | A182 F53 | A890 Gr 6A |

| Zeron 100 | S32760 | 1.4501 | A182 F55 | A351 GR CD3MWCuN |

| Ferralium® 255 | S32550 | 1.4507 | A182 F61 | |

| Nicrofer 5923 hMo | N06059 | 2.4605 | B462 N06059 | |

| Nickel 200 | N02200 | 2.4066 | B564 N02200 | |

| Nickel 201 | N02201 | 2.4068 | B564 N02201 | |

| Monel® 400 | N04400 | 2.436 | B564 N04400 | A494 M35-1 |

| Monel® K500 | N05500 | 2.4375 | B865 N05500 | |

| Incoloy® 800 | N08800 | 1.4876 | B564 N08800 | |

| Incoloy® 800H | N08810 | 1.4958 | B564 N08810 | |

| Incoloy® 800HT | N08811 | 1.4959 | B564 N08811 | |

| Incoloy® 825 | N08825 | 2.4858 | B564 N08825 | |

| Inconel® 600 | N06600 | 2.4816 | B564 N06600 | A494 CY40 |

| Inconel® 625 | N06625 | 2.4856 | B564 N06625 | A494 CW 6MC |

| Hastelloy® B2 | N10665 | 2.4617 | B564 N10665 | A494 N 12MV |

| Hastelloy® B3 | N10675 | 2.46 | B564 N10675 | |

| Hastelloy® C22 | N06022 | 2.4602 | B574 N06022 | A494 CX2MW |

| Hastelloy® C276 | N10276 | 2.4819 | B564 N10276 | |

| Hastelloy® C4 | N06455 | 2.461 | B574 N06455 | |

| Titanium GR. 1 | R50250 | 3.7025 | B381 F1 | B367 C1 |

| Titanium GR. 2 | R50400 | 3.7035 | B381 F2 | B367 C2 |

| Titanium GR. 3 | R50550 | 3.7055 | B381 F3 | B367 C3 |

| Titanium GR. 5 | R56400 | 3.7165 | B381 F5 | B367 C5 |

| Titanium GR. 7 | R52400 | 3.7235 | B381 F7 | B367 C7 |

| Titanium GR. 12 | R53400 | 3.7225 | B381 F12 | B367 C12 |

| Zirconium® 702 | R60702 | B493 R60702 | ||

| Zirconium® 705 | R60705 | B493 R60705 |

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.