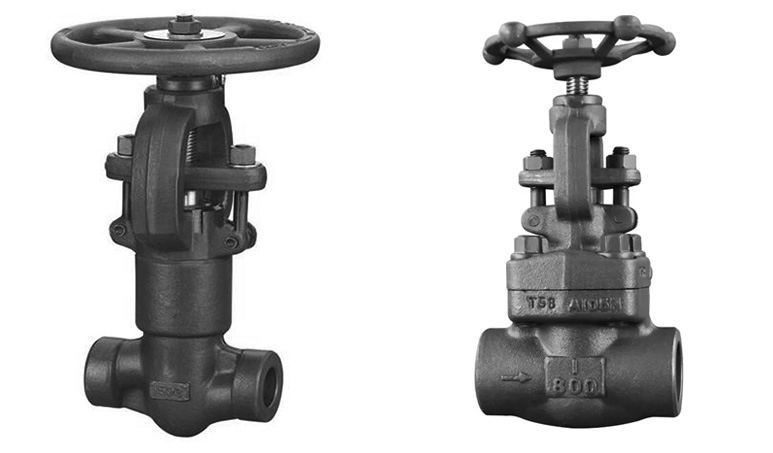

Forged steel globe valves are divided into forged carbon steel globe valves and forged stainless steel globe valves, generally used in high and medium pressure occasions (150lb-800lb, 1500LB, 2500LB), as well as high and low temperature occasions (-196℃ ~ 700℃), forged steel valves have higher strength and better mechanical properties to meet higher pressure requirements. But limited to the forging process, often only applies to small and medium size (1/2 “, 3/4 “, 1 “, 1-1/4 “, 1-1/2 “, 2, 2-1/2 “, 3 “and 4″).

The Valve Operation can be manual, bevel gear, pneumatic actuator, electric actuator, hydraulic actuator, pneumatic-hydraulic , electro-hydraulic.

Forged steel globe valve structure advantages

1. Forged steel globe valve adopts pressure self-tightening seal, and both ends of the valve body branch pipe are welded.

2. Forged steel globe valve valve seat, valve disc sealing surface is made of cobalt-based cemented carbide plasma spray welding, wear resistance, high abrasion resistance.

3. The valve stem is treated with corrosion resistance nitriding, which has good corrosion resistance and abrasion resistance.

4 in the opening and closing process, due to the valve disc in the valve body sealing surface friction is small, and wear resistance.

5. Usually there is only one sealing face on the valve body and disc, so the manufacturing process is better and convenient for maintenance

The valve must be inspected before installation, and the valve design standard should be in accordance with the current international standard API 602. The strength and tightness performance test should be carried out before installation.

In the strength test, the test pressure is 1.5 times of the nominal pressure, and the duration is not less than 5min.

The valve shell and back seat sealing should be qualified without leakage.

Sealing test, the test pressure is 1.1 times of the nominal pressure;

The test pressure in the test duration time should meet the REQUIREMENTS of API 598 standard, with no leakage on the disc sealing surface as qualified.

Post time: Aug-20-2021