Pipeline Valves play a vital role in pipeline systems. They are of various types and have different functions. In daily work, we often hear various valve names, which are sometimes even confusing. In order to help everyone better understand valves, especially those common types, I decided to compile an overview of common valve types. I hope this information can help everyone. Let’s explore the mystery of valves together. Let’s learn about the commonly used pipeline valves.

Commonly Used Pipeline Valves are as follows

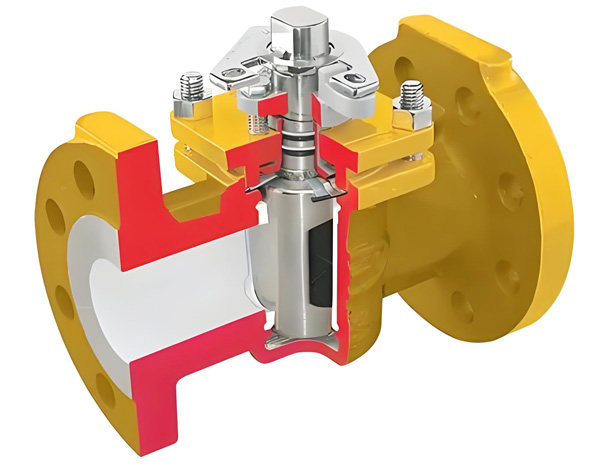

Ball valve

- Brief description of working principle: The core component of the ball valve is a sphere with a hole. Its working principle is based on the rotation of this sphere to control the on and off of the fluid. Just rotate 90 degrees, and the ball valve can achieve full open or full closed state switching, which is easy and quick to operate.

- Features: Excellent sealing performance, easy operation, low fluid resistance, intuitive and easy to understand structure, easy to open and close quickly.

- Application scenario: Commonly used in water treatment, petrochemical, natural gas transportation and other occasions, especially suitable for the needs of automatic control systems.

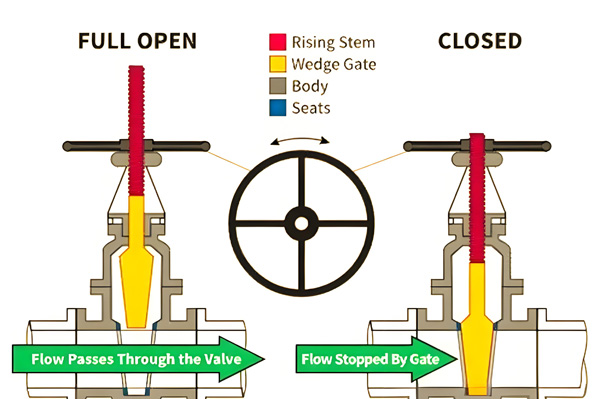

Gate valves

- Working principle: This valve controls the flow of fluid by lifting the gate, which is very suitable for fully open or fully closed working conditions, but not suitable for occasions that require precise flow adjustment.

- Features: The gate valve has good sealing performance, but it takes a long time to switch, and is not suitable for frequent operation.

- Application scenarios: It is mainly used in large-diameter, high-pressure pipelines to completely cut off fluids such as water, steam, oil and natural gas.

Butterfly valve

- Working principle:The structure of the butterfly valve is designed to be quite compact, with a small size and light weight. It achieves precise flow adjustment or effective fluid cut-off by rotating the butterfly plate.

- Features:It opens and closes quickly, but the sealing is relatively weak.

- Application scenarios:It is mainly suitable for large-diameter, low-pressure pipeline systems, such as water supply and drainage, cooling water circulation and other fields.

Globe valve

- Working principle: By rotating the handwheel, the valve disc is driven to move up and down, thereby achieving precise control of the fluid. This design is particularly suitable for occasions that require flow adjustment and frequent operation.

- Features: Excellent sealing performance, quick opening and closing, but relatively large fluid resistance, complex structure, resulting in relatively high pressure loss.

- Application: Mainly suitable for industrial scenarios that require flow regulation, such as boilers, HVAC systems, and steam pipes.

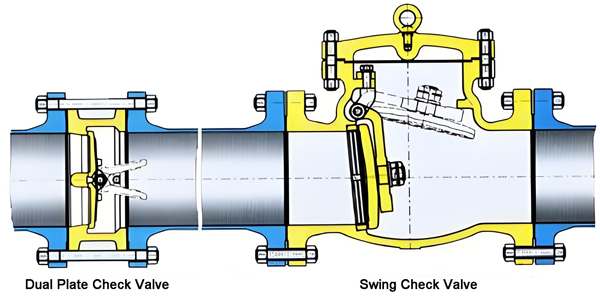

Check valve

- Working principle: It belongs to the automatic valve category, which prevents the backflow of the medium and protects the pipeline from damage by the water hammer effect. It is also called a check valve, a one-way valve, a reflux valve or an isolation valve. The valve disc movement mode is divided into lifting type and swing type.

- Features: The function of this type of valve is to allow the medium to flow in one direction only and prevent the flow in the opposite direction. It is an important component to ensure the safety of the system.

- Application scenario: Commonly used in equipment such as boilers and pressure vessels, the check valve is used in combination with the stop valve to play a role in safety isolation.

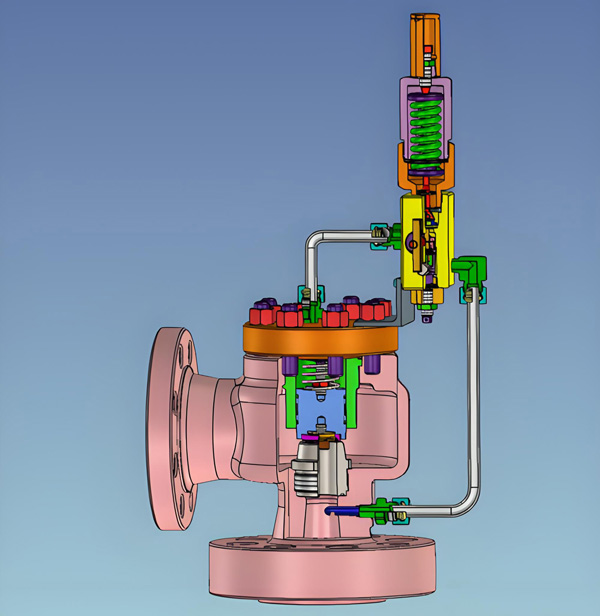

Pressure relief valve

- Working principle: When the system pressure exceeds the preset threshold, the safety valve will start spontaneously to release the excessive pressure to ensure that the equipment and system are not damaged by overpressure. Once the pressure drops back to the safe range, the valve will automatically close and return to normal.

- Features: Pressure relief valves are known for their high sensitivity. They can respond quickly and automatically to pressure changes in the system, effectively prevent system pressure from exceeding the standard, and thus ensure the safe operation of the equipment.

- Application scenarios:Safety valves are widely used in the field of overpressure protection of equipment such as boilers, pressure vessels, and pipeline systems, and are indispensable safety devices.

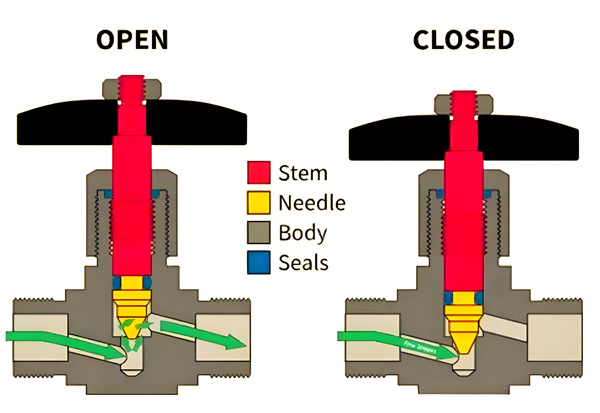

Instrument valve (Needle valve)

- Working principle: By rotating the handwheel, the needle valve core can be driven to move up and down, thereby realizing the precise regulation and control of fluid flow.

- Features: It has precise flow control and good sealing, and is particularly suitable for high-pressure and small-flow systems, but the opening and closing speed is relatively slow.

- Application scenarios: Plug valves are widely used in laboratory equipment, gas or liquid regulation systems, and high-pressure and small-flow control.

Plug valve

- Working principle description: The plug valve adjusts the relative position of the plug channel and the pipeline by rotating the cylindrical or conical plug to realize the opening and closing control of the fluid.

- Features: The plug valve has a compact structure, is easy to operate, and has a fast opening and closing action, which is very suitable for occasions that require frequent switching.

- Application areas: It plays a vital role in the pipeline systems of the natural gas, petroleum and chemical industries, and is widely used in fluid control in these fields.

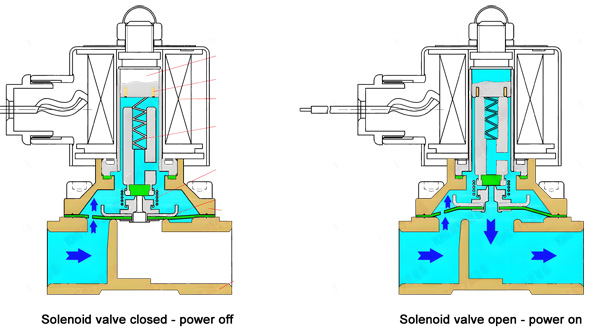

Solenoid valve

- Working principle: In the solenoid valve, the power on and off of the electromagnetic coil will cause changes in the electromagnetic force, which will then drive the movement of the valve core to open or close the valve. When the electromagnetic coil is de-energized, the valve core will reset and the valve will close.

- Features: The plug valve responds quickly and supports remote control, making it very suitable for use in automation systems.

- Application scenarios: It plays a key role in automatic control systems, for example, for automatic opening and closing control of water, gas and oil pipelines. However, there are many types of valves, far more than just plug valves.

In Summary

Pipeline valves are control components in pipeline fluid delivery systems, with functions such as shutoff, regulation, diversion, backflow prevention, pressure stabilization, flow diversion or overflow pressure relief. Valves used in fluid control systems have a wide variety of varieties and specifications.

Post time: Feb-12-2025