When it comes to fluid control in piping systems, two of the most commonly used valves are ball valves and gate valves. Both serve the essential function of regulating the flow of liquids and gases, but they do so in different ways and are suited for different applications. Understanding the differences between these two types of valves is crucial for engineers, plumbers, and anyone involved in the design or maintenance of piping systems. In this article, we will explore the characteristics, advantages, disadvantages, and applications of ball valves and gate valves, helping you make an informed decision for your specific needs.

Overview of Ball Valves

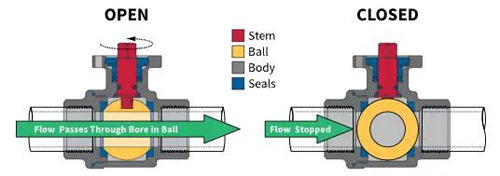

A ball valve is a type of quarter-turn valve that uses a hollow, perforated, and pivoting ball to control flow. When the valve is open, the hole in the ball is aligned with the flow direction, allowing fluid to pass through. When the valve is closed, the ball rotates 90 degrees, blocking the flow. Ball valves are known for their durability, reliability, and ability to provide a tight seal, making them ideal for applications where quick shut-off is necessary.

Key Features of Ball Valves

- Design: Ball valves typically have a simple design with fewer moving parts, which contributes to their reliability and ease of maintenance.

- Operation: They can be operated manually with a lever or automatically with an actuator, allowing for remote control.

- Flow Control: Ball valves provide excellent flow control and can handle high-pressure applications.

- Sealing: The sealing mechanism in ball valves is effective, minimizing the risk of leaks.

Advantages of Ball Valves

- Quick Operation: Ball valves can be opened or closed with a quarter turn, making them ideal for applications requiring rapid shut-off.

- Low Pressure Drop: The design of ball valves allows for minimal resistance to flow, resulting in a low-pressure drop across the valve.

- Versatility: They can be used in a wide range of applications, including water, gas, and oil systems.

- Durability: Ball valves are built to withstand high pressures and temperatures, making them suitable for demanding environments.

Disadvantages of Ball Valves

- Not Ideal for Throttling: While ball valves can regulate flow, they are not designed for throttling applications, as partially opening the valve can cause turbulence and damage the ball.

- Ball Valve Prit: Ball valves can be more expensive than other types of valves, such as gate valves, depending on the materials and design.

Overview of Gate Valves

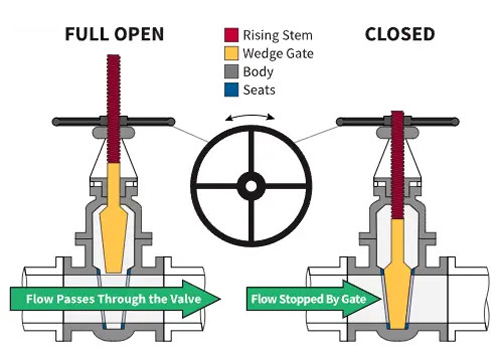

Gate valves are linear motion valves that use a gate or wedge to control the flow of fluid. When the valve is fully open, the gate is lifted out of the flow path, allowing fluid to pass through with minimal resistance. When the valve is closed, the gate is lowered into the flow path, creating a seal that prevents fluid from passing. Gate valves are commonly used in applications where a straight-line flow of fluid and minimum pressure drop are desired.

Key Features of Gate Valves

- Design: Gate valves have a more complex design with a gate mechanism that can be either rising or non-rising.

- Operation: They require multiple turns of the handle to open or close, which can be a disadvantage in applications requiring quick shut-off.

- Flow Control: Gate valves are designed for full flow and are not suitable for throttling.

- Sealing: The sealing mechanism can be less effective than that of ball valves, especially in high-pressure applications.

Advantages of Gate Valves

- Minimal Pressure Drop: When fully open, gate valves provide a straight flow path, resulting in minimal pressure drop.

- Gate Valve Price: Gate valves are generally less expensive than ball valves, making them a cost-effective choice for many applications.

- Suitable for Large Pipelines: They are often used in large-diameter pipelines where a full flow is required.

Disadvantages of Gate Valves

- Slow Operation: The need for multiple turns to open or close the valve can be a disadvantage in applications requiring quick response times.

- Potential for Leakage: Over time, gate valves can develop leaks, especially if they are not maintained properly.

- Not Suitable for Throttling: Like ball valves, gate valves are not designed for throttling applications, as partially opening the valve can lead to damage.

Key Differences Between Ball Valves and Gate Valves

1. Operation Mechanism

The primary difference between ball valves and gate valves lies in their operation mechanism. Ball valves use a spherical ball to control flow, while gate valves use a gate or wedge. This difference affects how quickly each valve can be opened or closed, with ball valves allowing for rapid operation and gate valves requiring multiple turns.

2. Flow Characteristics

Ball valves provide a tight seal and are excellent for applications requiring quick shut-off. In contrast, gate valves are designed for full flow and minimal pressure drop when fully open. However, they are not suitable for throttling, as partially opening a gate valve can lead to turbulence and potential damage.

3. Sealing Performance

Ball valves generally offer better sealing performance than gate valves, making them less prone to leaks. The design of the ball valve allows for a more effective seal, especially in high-pressure applications. Gate valves, on the other hand, may develop leaks over time, particularly if not maintained properly.

4. Cost and Maintenance

In terms of cost, gate valves are typically more affordable than ball valves. However, ball valves may require less maintenance due to their simpler design and better sealing capabilities. The choice between the two may depend on budget constraints and the specific requirements of the application.

5. Applications

Ball valves are commonly used in applications where quick shut-off is essential, such as in gas and oil pipelines, water treatment plants, and HVAC systems. Gate valves are often found in applications requiring full flow, such as in water supply systems, irrigation, and wastewater treatment.

Conclusion

In summary, both ball valves and gate valves play crucial roles in fluid control systems, but they have distinct characteristics that make them suitable for different applications. Ball valves are ideal for situations requiring quick shut-off and excellent sealing performance, while gate valves are better suited for applications where minimal pressure drop and full flow are essential. Understanding the differences between these two types of valves will help you make informed decisions when selecting the right valve for your specific needs. Whether you are designing a new piping system or maintaining an existing one, knowing when to use a ball valve versus a gate valve can significantly impact the efficiency and reliability of your fluid control system.

Post time: Feb-10-2025