There are significant differences between SDV valves (Shut-off valves) and safety valves in terms of function, working principle and application scenarios. The following is a detailed analysis of the difference between the two valves:

First, functional differences

SDV valve (cut-off valve) :

The main function is to cut off and control fluid flow. When an emergency occurs, the SDV valve can quickly cut off the flow of media, prevent the expansion of accidents, and ensure the safety of personnel and equipment.

Safety valve:

The main function is to prevent equipment or pipeline damage due to overpressure. When the medium pressure in the equipment or pipeline exceeds the specified value, the safety valve automatically opens, and the pressure is reduced by discharging the medium to the outside of the system, thus protecting the safety of the equipment and pipeline.

Second, differences in working principles

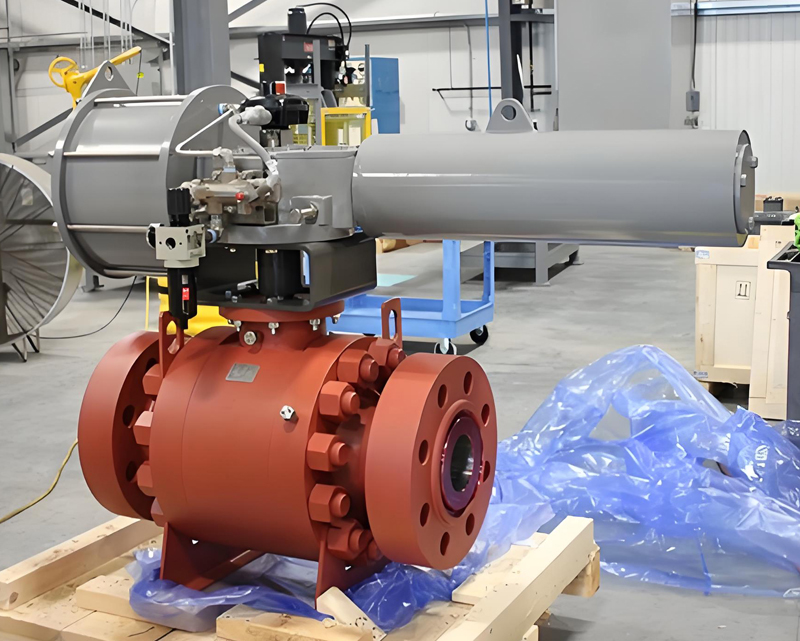

SDV valve (cut-off valve) :

The working principle is based on pneumatic actuators. After receiving the control signal, the solenoid valve controls the on-off of the compressed air source, thereby driving the opening or closing of the valve. SDV valves are only fully open and fully closed, so they are also known as two-position valves.

Safety valve:

The working principle is based on the force of a spring or a weight. When the medium pressure exceeds the specified value, the spring or weight is compressed or moved, thus opening the valve to release the pressure. When the pressure is reduced to the set value, the spring or weight recovers and the valve automatically closes.

Third, differences in application scenarios

SDV valve (cut-off valve) :

Widely used in petrochemical, pharmaceutical, food, shipbuilding and other industries, as well as offshore oil platforms. It is especially suitable for situations where the media flow needs to be quickly cut off to protect equipment and systems.

Safety valve:

It is mainly used in boilers, pressure vessels, pipeline systems and other equipment to prevent equipment damage and safety accidents caused by overpressure. Safety valves are also commonly used in steam boilers, liquefied petroleum gas tanker or liquefied petroleum gas railway tank cars, production Wells, steam power generation equipment high-pressure bypass and other occasions.

Fourth, other differences

Structural features:

The structure of the SDV valve (cut-off valve) is relatively simple, usually including two parts of the actuator and the valve body. The actuator can be pneumatic, electric or hydraulic, etc., and the valve body can be selected according to the characteristics of the medium and the requirements of use.

The structure of the safety valve is relatively complex, usually including the body, seat, valve disc, spring or weight and other components. Different structural forms of safety valves (such as spring type, lever weight type, pulse type, etc.) have different characteristics and scope of application.

Performance requirements:

The performance requirements of SDV valve (cut-off valve) mainly include sealing performance, opening and closing speed, service life and so on. In the selection, it is necessary to choose according to the actual working conditions and media characteristics.

The performance requirements of the safety valve are more stringent, in addition to the basic sealing performance and opening and closing speed, but also need to consider the discharge capacity, return pressure, opening and closing pressure difference and other key indicators. These indicators directly affect the protection effect of the safety valve and the safe operation of the system.

In summary, there are significant differences between SDV valves (cut-off valves) and safety valves in terms of function, working principle, application scenarios and structural characteristics. The selection needs to be comprehensively considered according to the actual use needs and working conditions.

Post time: Nov-11-2024