There are significant differences between check valves and relief valves in many aspects, which are mainly reflected in their function, structure, working principle and application scenarios. Here’s a breakdown:

Functional differences

Check valve: The main function is to prevent the media from flowing back in the pipeline. It allows the media to flow freely in one direction, but when the media flows in reverse, the check valve will automatically close to prevent the media backflow from causing damage to the system. The check valve also plays an important role in preventing the pump and its drive motor from reversing and preventing the media in the container from leaking.

Relief valve: The main function is to prevent the pressure in the system or equipment from exceeding the specified value. When the pressure exceeds the set value, the safety valve will automatically open and release part of the medium to reduce the pressure, thereby protecting the safety of the equipment and system. Safety valve is an important device to protect equipment and personnel from excessive pressure.

Structural differences

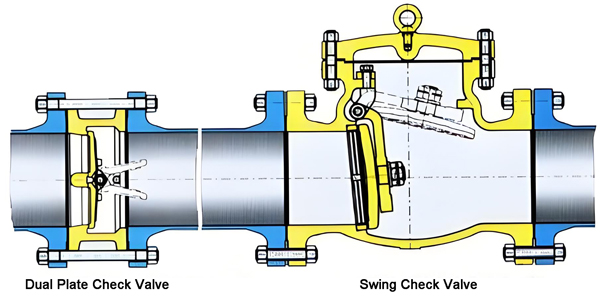

Check valve: The structure is relatively simple, usually by the body, valve cover, valve spring and seat and other parts. Its working principle mainly relies on the force generated by the flow of the medium to open and close the valve.

Safety valve: The structure is relatively complex, usually by the valve body, spring, shrapnel, guide parts and other parts. These components work together to ensure that the safety valve opens and closes accurately when the set pressure is reached. The structural design of the safety valve needs to consider the pressure, temperature, flow and other factors of the medium.

Difference in working principle

Check valve: The working principle is based on the force generated by the flow of the medium. When the medium flows forward in the pipe, the force generated by the medium pushes the disc of the check valve open and allows the medium to pass through. When the medium flows in reverse, the valve disc will be subjected to the combined action of the medium and the valve spring to close the valve, thereby preventing the medium from flowing back.

Safety valve: The working principle is based on pressure control. When the pressure in the system or equipment exceeds the set value, the spring of the safety valve is compressed to a certain extent, and the valve will open and release part of the medium to reduce the pressure. When the pressure drops below the set value, the spring returns to position and closes the valve.

Difference between application scenarios

Check valve: widely used in chemical, petroleum and other industrial fields of pipeline system. It is mainly used to prevent damage to the system caused by the media backflow, such as preventing the pump and its drive motor from reversing, preventing the media in the container from leaking.

Safety valve: also widely used in chemical, electric power, petroleum, metallurgy and other industries of equipment or facilities. Especially in boilers, pressure vessels, pipelines and other systems, safety valves are important protection devices to prevent equipment from being damaged due to high pressure.

In summary

There are significant differences between check valves and safety valves in terms of function, structure, working principle and application scenarios. In practical applications, appropriate valve types need to be selected according to specific needs and scenarios to ensure the normal operation and safety of equipment and systems.

Post time: Oct-28-2024