What is the Flow Coefficient

The Flow Coefficient, known as Cv (US/EU Standard), Kv (International Standard), or C-value, is a critical technical parameter defining the flow capacity of industrial valves like control valves and regulators.

Defining Cv Value

Valve Cv represents the flow coefficient indicating a valve’s capacity to pass fluid under specific conditions. It quantifies the volume flow rate of liquid or gas through a valve at a given pressure drop. Higher Cv values indicate greater flow capacity.

What is Cv (Capacity Value)

Valve Cv (Capacity Value) measures flow capacity and is calculated under standardized test conditions:

• Valve fully open

• Pressure drop (ΔP) of 1 psi across the valve

• Fluid: Water at 60°F (15.5°C)

• Flow rate: US gallons per minute (GPM)

Valve Opening vs. Cv Value

Cv/Kv and valve opening (%) are distinct concepts:

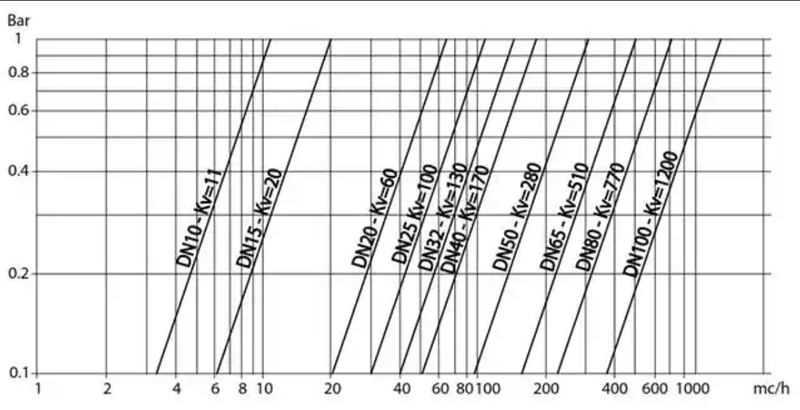

• Kv Definition (China Standard): Flow rate in m³/h when ΔP = 100 kPa, fluid density = 1 g/cm³ (water at room temperature).

*Example: Kv=50 means 50 m³/h flow at 100 kPa ΔP.*

• Opening Percentage: Position of valve plug/disc (0% = closed, 100% = fully open).

Calculating Cv & Key Applications

Cv is influenced by valve design, size, material, flow regime, and fluid properties (temperature, pressure, viscosity).

The core formula is:

Cv = Q / (√ΔP × √ρ)

Where:

• Q = Volumetric flow rate

• ΔP = Pressure differential

• ρ = Fluid density

Conversion: Cv = 1.167 Kv

Role in Valve Selection & Design

Cv directly impacts fluid control system efficiency:

• Determines optimal valve size and type for target flow rates

• Ensures system stability (e.g., prevents pump cycling in building water supply)

• Critical for energy optimization

Cv Variations Across Valve Types

Flow capacity differs by valve design (data sourced from ASME/API/ISO standards):

| Valve Type | Key Characteristics | Example Cv (FCI Standard) |

|---|---|---|

Gate Valve |

Medium Cv (DN100 ≈ 400); poor regulation; avoid <30% opening (turbulence risk per ASME B16.34) | DN50: ~120 |

Ball Valve |

High Cv (1.8× gate valves); linear flow control; API 6D recommended for pipelines | DN80 V-ball: ≈375 |

Butterfly Valve |

Cost-effective for large sizes; ±5% precision (triple-offset); limited flow gain >70% open | DN150 Wafer: ~2000 |

Globe Valve |

High resistance (Cv ≈ 1/3 of ball valves); precise control (medical/lab use) | DN50: ~40 |

Core Flow Parameters & Influencing Factors

Valve performance is defined by three parameters (per Fluid Controls Institute):

1. Cv Value: GPM flow at 1 psi ΔP (e.g., DN50 ball valve ≈ 210 vs. gate valve ≈ 120).

2. Flow Resistance Coefficient (ξ):

• Butterfly valve: ξ = 0.2–0.6

• Globe valve: ξ = 3–5

Selection Guidelines & Critical Considerations

Viscosity Correction:

Apply multipliers to Cv (e.g., crude oil: 0.7–0.9 per ISO 5208).

Smart Valves:

Real-time Cv optimization (e.g., Emerson DVC6200 positioner).

Flow Coefficient Testing Systems

Testing requires controlled conditions due to measurement sensitivity:

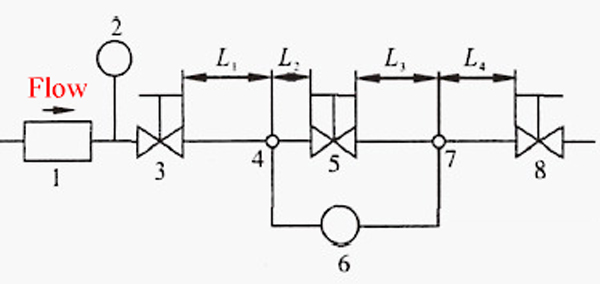

• Setup (Per Fig. 1):

Flowmeter, thermometer, throttling valves, test valve, ΔP gauge.

1. Flow meter 2. Thermometer 3. Upstream throttle valve 4 and 7. Pressure tapping holes 5. Test valve 6. Pressure differential measuring device 8. Downstream throttle valve

4. The distance between the pressure tapping hole and the valve is 2 times the pipe diameter

7. The distance between the pressure tapping hole and the valve is 6 times the pipe diameter

• Key Controls:

- Upstream valve regulates inlet pressure.

- Downstream valve maintains stable pressure (nominal size > test valve to ensure choked flow occurs in test valve).

• Standards:

JB/T 5296-91 (China) vs. BS EN1267-1999 (EU).

• Critical Factors:

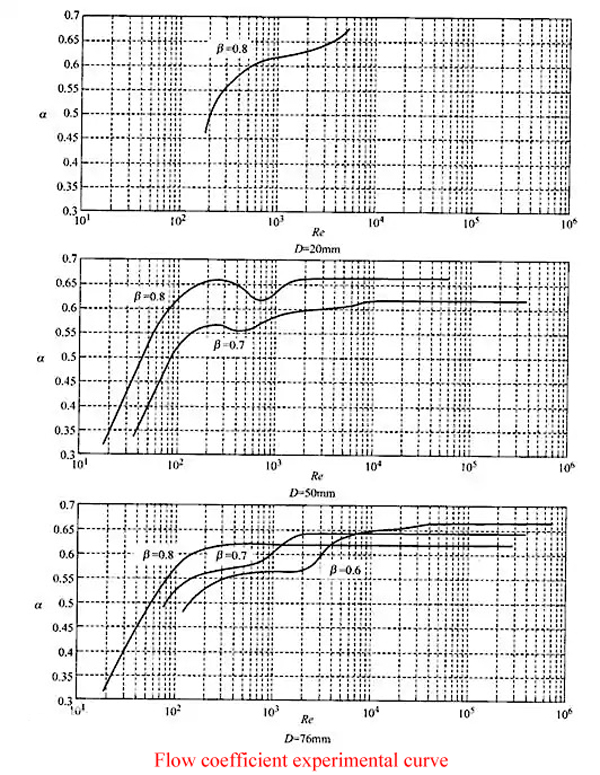

Tap location, piping configuration, Reynolds number (liquids), Mach number (gases).

Testing Limitations & Solutions:

• Current systems test valves ≤DN600.

• Larger valves: Use air-flow testing (not detailed here).

Impact of Reynolds Number: Experimental data confirms Reynolds number significantly affects test results.

Key Takeaways

• Cv/Kv defines valve flow capacity under standardized conditions.

• Valve type, size, and fluid properties critically impact Cv.

• Testing requires strict adherence to protocols (JB/T 5296-91/BS EN1267) for accuracy.

• Corrections apply for viscosity, temperature, and pressure.

(All data sourced from ASME/API/ISO standards and valves manufacturer whitepapers.)

Post time: Jan-06-2025