What is the Purpose of A Ball Valve

Ball valves are essential components in a variety of piping systems and are a reliable means of controlling the flow of liquids and gases. The ball valve design features a spherical disc (“ball”) that rotates within the valve body, allowing for a quick and effective shutoff function. In this article, we will explore the different types of ball valves, including 3/4-inch, 1/2-inch, 1-inch, and 3-way configurations, and their applications in various industries, with a special focus on stainless steel options and their use in gas systems.

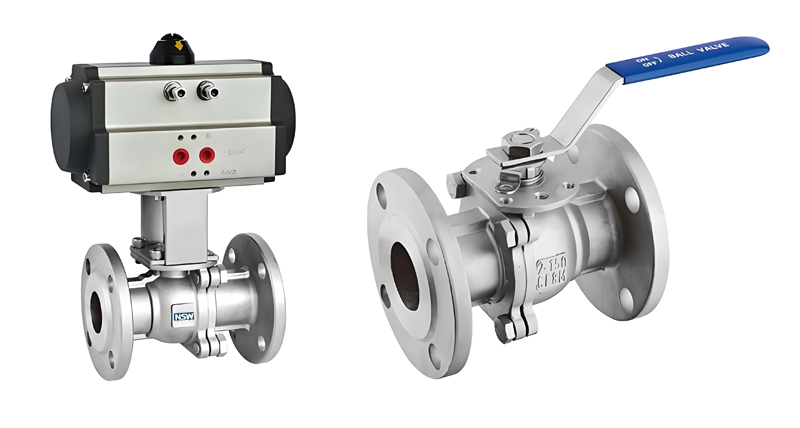

Understanding Ball Valves

What is a ball valve

A ball valve is a quarter-turn valve that uses a hollow, perforated rotating ball to control flow. When the ball hole is aligned with the direction of flow, the valve opens, allowing fluid to pass. When the ball is rotated 90 degrees, flow is shut off. This simple yet effective mechanism makes ball valves a popular choice for many applications.

Ball valve type

1. 1/2″ Ball Valve: This smaller size is often used in residential plumbing systems where space is limited and precise control of water flow is required. It is ideal for applications such as sink faucets and shower valves.

2. 3/4″ Ball Valve: Slightly larger than a 1/2″ ball valve, the 3/4″ ball valve is often used in irrigation systems and large plumbing applications. It offers a good balance between flow capacity and space requirements.

3. 1-inch ball valve: This size is often used in commercial and industrial applications that require higher flow rates. It is suitable for larger piping systems, such as those in manufacturing plants or large buildings.

4. Three-way ball valve: A three-way ball valve has three ports that can control flow between two different paths. This type of ball valve is particularly useful in applications where flow needs to be redirected or mixed, such as in heating systems or chemical processing.

Materials used for ball valves

Ball valves can be made from a variety of materials, but stainless steel is one of the most popular choices due to its durability and corrosion resistance. Stainless steel ball valves are ideal for applications involving water, oil, and gas because they can withstand high pressures and temperatures without degradation.

Application of ball valve

1. Residential plumbing

In residential settings, ball valves are often used for shutoff applications. For example, a 1/2″ or 3/4″ ball valve can be installed under a sink or behind a toilet for easy maintenance and repair. Their quick shutoff feature makes them ideal for preventing water damage in emergency situations.

2. Industrial Applications

In industrial settings, ball valves are used to control the flow of a variety of fluids, including water, oil, and chemicals. The 1-inch ball valve is particularly popular in these environments because of its ability to handle large volumes of fluid. Stainless steel ball valves are preferred in these applications because of their strength and corrosion resistance, ensuring long life and reliability.

3. Gas System

Ball valves are also widely used in natural gas systems where safety and reliability are critical. Ball valves used in natural gas applications must be designed to withstand high pressures and prevent leaks. Stainless steel materials are often used in these systems due to their ability to resist corrosion and maintain integrity over time. The quick closing feature of ball valves is critical in natural gas applications, allowing for immediate action in the event of a leak or emergency.

4. HVAC system

In heating, ventilation, and air conditioning (HVAC) systems, ball valves are used to control the flow of water and refrigerants. A three-way ball valve is particularly useful in these applications because it can change the direction of flow between different components of the system, such as a radiator or cooling coil.

5. Agricultural Applications

In agriculture, ball valves are used in irrigation systems to control the amount of water flowing to crops. 3/4″ ball valves are commonly used in these systems and provide a reliable method for effectively managing water resources.

Advantages of using ball valve

1. Quick operation: The ball valve can be opened or closed by just rotating a quarter of a turn, which is easy to operate.

2. Durability: Stainless steel ball valves are corrosion-resistant and can withstand harsh environments, making them a long-lasting choice.

3. Low Pressure Drop: Ball valves are designed to minimize flow resistance, resulting in a low pressure drop across the valve.

4. Versatility: Ball valves can be used in a wide range of applications, from residential plumbing to industrial processes.

5. Leak-free Seal: When closed, the ball valve provides a tight seal, preventing leakage and ensuring safety for gas and liquid applications.

In summary

Ball valves are an essential component of many plumbing systems, providing reliable flow control for a variety of applications. Whether you use 1/2-inch ball valves for residential plumbing, 3/4-inch valves for irrigation, or 1-inch valves for industrial settings, their quick-closing capabilities and durability make them an excellent choice. Stainless steel ball valves are favored for their corrosion resistance and ability to withstand high pressures, making them ideal for gas systems and other demanding applications. Understanding the different types of ball valves and their uses can help you make an informed decision when choosing the right valve for your needs.

Post time: Jan-30-2025