A shut off valve is a critical component in piping systems designed to control the flow of liquids or gases. By opening, closing, or partially obstructing pathways, these valves ensure safety, regulate pressure, and prevent leaks. Whether in residential plumbing, industrial processes, or oil and gas pipelines, shut off valves are indispensable for system efficiency and emergency management.

Types of Shut Off Valves

Shut off valves come in various designs, each suited for specific applications. Here are the most common types:

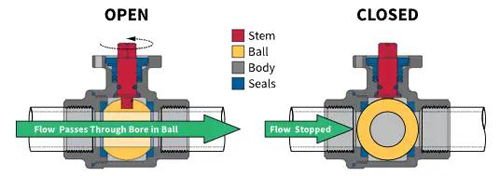

Ball Valve

A ball valve uses a rotating ball with a bore to control flow. It offers quick shut-off, durability, and minimal pressure drop. Ideal for water, gas, and oil systems.

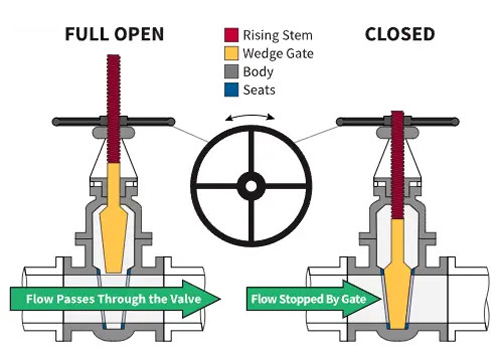

Gate Valve

Gate valves feature a wedge-shaped gate that lifts to allow flow. They’re best for on/off control in low-frequency applications, such as water supply lines.

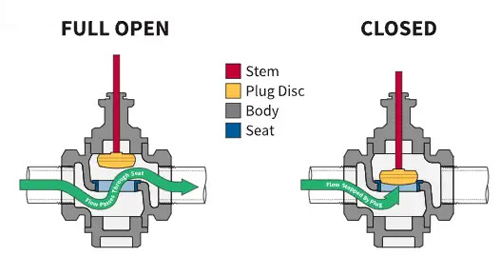

Globe Valve

Known for precise flow regulation, globe valves use a disc and seat mechanism. Common in HVAC systems and fuel pipelines.

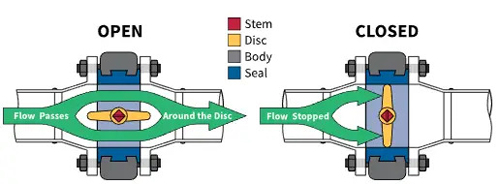

Butterfly Valve

A compact, lightweight valve with a rotating disc. Butterfly valves excel in large-scale water treatment and fire protection systems.

Check Valve

Allows flow in one direction only, preventing backflow. Used in sewage systems and pump discharge lines.

Diaphragm Valve

Utilizes a flexible diaphragm to isolate flow. Ideal for corrosive or slurry fluids in chemical processing.

Needle Valve

Designed for precise flow control with a tapered needle-like plunger. Common in instrumentation and hydraulic systems.

ESDV (Emergency Shutdown Valve)

A specialized valve for rapid closure during emergencies, often automated. Critical in oil refineries and gas pipelines.

Uses of Shut Off Valves

Shut off valves serve diverse roles across industries:

- Residential: Isolate water supply during repairs (e.g., ball valves under sinks).

- Industrial: Regulate steam, chemicals, or fuels (globe valves, diaphragm valves).

- Oil & Gas: Ensure safety with ESDVs during leaks or pressure surges.

- Fire Protection: Butterfly valves enable rapid water flow control in sprinkler systems.

- Pharmaceuticals: Needle valves maintain precision in fluid handling.

How Do Shut Off Valves Work

The operating mechanism varies by type but follows a general principle:

1. Actuation: Valves are operated manually (handwheel, lever) or automatically (electric/pneumatic actuators).

2. Flow Control:

– Ball/Butterfly Valves: Rotate 90° to open/close.

– Gate/Globe Valves: Linear motion raises/lowers the gate or disc.

– Check Valves: Rely on flow pressure to open/close.

3. Sealing: Tight seals (rubber, PTFE) prevent leaks when closed.

Choosing the Right Valve

Selecting a shut off valve depends on factors like:

- Fluid Type: Corrosive fluids demand diaphragm valves; gases suit ball valves.

- Pressure/Temperature: High-pressure systems require robust ESDVs or gate valves.

- Frequency of Use: Ball valves last longer in high-cycle applications.

Conclusion

From ESDVs in hazardous environments to simple ball valves in homes, shut off valves are the backbone of fluid control systems. Understanding their types, uses, and mechanics ensures optimal performance and safety. Regular maintenance and correct valve selection further enhance system longevity.

Post time: Feb-21-2025