What is a Globe Valve

A globe valve is a valve used to regulate the flow of fluids in a piping system. Its design features a spherical body with an internal baffle that creates a flow path, allowing precise control of flow rate. Globe valves are characterized by their ability to provide a tight seal, making them ideal for applications where flow regulation is critical.

Globe valves are commonly used in a variety of industries, including oil and gas, water treatment, and power generation. They are particularly effective in throttling applications where frequent flow adjustments are required. The valve’s design allows for a smooth flow path, minimizing turbulence and pressure drop, which is critical to maintaining system efficiency.

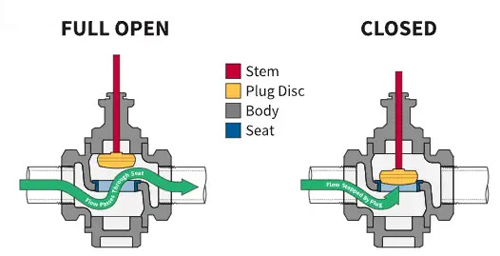

How Globe Valves Work

Globe valves control fluid flow using a linear motion mechanism between the disc (plug) and seat. Key principles include:

Disc-Seat Interaction: The disc moves vertically to adjust the flow area. Tight contact with the seat ensures a leak-proof seal.

Forced Sealing: Torque applied to the stem presses the disc against the seat, preventing leakage.

Unidirectional Flow: Fluid typically flows upward through the valve, reducing closing force and enhancing sealing.

Throttling Capability: Ideal for precise flow adjustments due to their linear stroke design.

Key Features of Globe Valves

Precise Flow Control: Linear disc movement enables fine-tuning of flow rates.

Robust Sealing: Metal, composite, or soft seals ensure leak-free performance.

High-Pressure Tolerance: Suitable for steam systems and high-pressure differentials.

Compact Design: Easy to install and maintain with minimal space requirements.

Multi-Media Compatibility: Works with water, steam, oil, gas, and corrosive fluids.

Manual or Automated Operation: Supports handwheels, electric actuators, or pneumatic systems.

Advantages of Using Globe Valves

Reliable Shut-Off: Superior sealing minimizes leakage risks.

Durability: Resistant to high temperatures and pressures.

Versatility: Compatible with diverse fluids and industries.

Ease of Maintenance: Simple structure reduces downtime.

Long Service Life: Low friction between sealing surfaces extends longevity.

Common Applications of Globe Valves

Oil & Gas: Pipeline flow control and emergency shutdowns.

Power Plants: Steam and coolant regulation in turbines.

Water Treatment: Precise throttling in distribution systems.

Pharmaceuticals: Hygienic fluid handling in GMP-compliant processes.

Aerospace: Oxygen supply control for engines and life-support systems.

Globe Valves vs. Other Valve Types

| Feature | Globe Valves | Gate Valves | Ball Valves |

|---|---|---|---|

| Flow Control | Excellent throttling | On/Off only | Moderate throttling |

| Sealing | Tight shut-off | Less precise | Quick seal |

| Pressure Drop | High | Low | Moderate |

| Maintenance | Easy | Complex | Simple |

Maintenance and Troubleshooting for Globe Valves

Routine Care:

Inspect seals, stems, and bolts for wear.

Lubricate stems and replace packing regularly.

Clean internal components to prevent clogging.

Common Issues & Fixes:

Leakage: Replace worn seals or realign the disc.

Stiff Operation: Lubricate the stem or check for debris.

Slow Response: Inspect actuators for malfunctions.

Selecting the Right Globe Valve

Consider these factors:

Media Type: Choose materials (e.g., stainless steel, brass) compatible with the fluid.

Pressure/Temperature: Verify ratings match system requirements.

Connection Type: Flanged, threaded, or welded ends.

Actuation: Manual, electric, or pneumatic based on automation needs.

Industry Standards and Regulations

API 600/6D: Standards for steel globe valves in oil and gas.

ISO 10434: Design and testing guidelines.

ASME B16.34: Pressure-temperature ratings.

BS 1873: British specifications for cast steel valves.

Conclusion and Future Trends in Valve Technology

Globe valves remain indispensable due to their precision and adaptability. Emerging trends include:

Smart Valves: IoT-enabled sensors for real-time monitoring.

Advanced Materials: Corrosion-resistant alloys and composites.

Sustainability: Energy-efficient designs and recyclable materials.

By understanding globe valves’ capabilities and innovations, industries can enhance system efficiency and longevity.

Globe Valve Manufacturer and Price

When considering buying a globe valve, it is important to choose a reliable globe valve manufacturer. A reputable manufacturer ensures that the valves are produced to high standards, using quality materials that will meet the needs of the application. NSW Valve Manufacturer in China are recognized for their advanced manufacturing processes and competitive prices.

The price of globe valves can vary greatly depending on factors such as size, material and manufacturer. When purchasing globe valves, it is recommended to compare prices from different suppliers to ensure that you are getting the best value for your investment.

In conclusion, globe valves are essential components in many industrial applications, providing effective flow control and regulation. By choosing a trusted globe valve manufacturer and considering the price and quality of the product, you can ensure optimal performance and longevity of your piping system. Whether you are looking for a globe valve factory in China or exploring options locally, understanding the fundamentals of globe valves will help you make informed decisions for your project.

Post time: Jan-10-2025