Full Port Ball Valve refers to the diameter of the flow channel inside the ball valve, which is one of the key parameters affecting the flow rate and use effect of the ball valve. In the design process of the bore ball valve, the size of the bore directly affects the flow rate and use effect of the ball valve. It is usually calculated and determined based on the flow rate or pipeline size. You can also consult the valve manufacturer.

Definition and Calculation Method of Full Port Ball Valve

1. Definition:

The Full port ball valve refers to the diameter of the flow channel inside the ball valve. In the design and use process, the bore directly affects the flow rate and use effect of the ball valve.

2. Calculation method:

Calculate the full port based on the flow rate: The commonly used method is to use the empirical formula

Q=K×Cv×ΔPQ=K×C v × ΔP,

The Q is the flow rate, K is the correction factor (generally 0.9), Cv is the flow coefficient, and ΔP is the pressure difference. Therefore, the calculation formula of the ball valve diameter

The d is the ball valve diameter in mm and 25.4 is the conversion factor. Calculate the diameter according to the pipeline size: In some specific occasions, the diameter can be determined according to the pipeline size, and the calculation formula is

d=D×0.8d=D×0.8

The d is the ball valve diameter and D is the outer diameter of the pipeline.

What is the Difference between a Regular Port and a Full Port Ball Valve

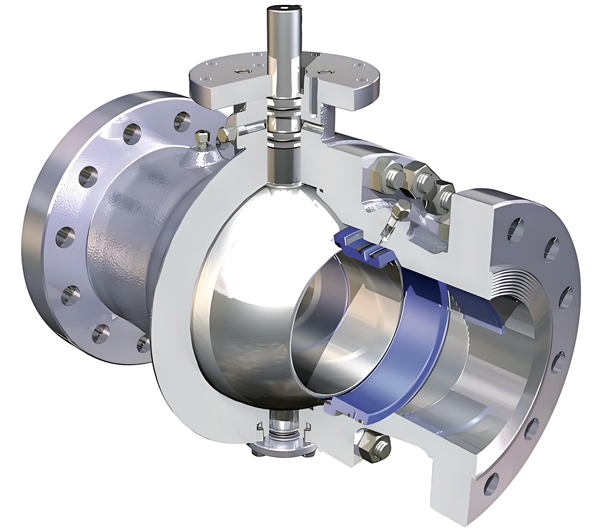

Full Port Ball Valve: The diameter of the through hole on the valve core ball is basically the same as the inner diameter of the pipeline. There is almost no obstruction when the fluid passes through the valve, and the full flow can be achieved, reducing the pressure loss of the fluid. Full-diameter ball valves are suitable for the transportation of large-flow fluids, especially in oil and natural gas pipelines.

Regular Port Ball Valve: The flow channel entrance is wider than the flow channel diameter, and the actual diameter is one specification smaller than the specification. For example, the flow path diameter of a DN50 reduced-diameter ball valve is about 38mm, which is roughly equivalent to the specification of DN40. Reduced-diameter ball valves are suitable for occasions where flow requirements are not high.

Application of Ball Valve

Oil and gas industry: Full-diameter ball valves are often used to cut off and control trunk pipelines to ensure the efficient transportation of large amounts of oil and gas, and to facilitate pipe cleaning during pipeline maintenance.

Chemical industry: In large-scale chemical production equipment, full-diameter ball valves are used to control high-flow fluids to ensure the continuity and stability of the production process.

Water supply and drainage and water treatment systems: Full-diameter ball valves are used in main pipelines of urban water supply and drainage systems, inlet and outlet pipes of large water treatment plants, and other occasions that require large flow transportation.

Post time: Feb-15-2025