Floating Ball Valve

The ball of the floating ball valve is floating. Under the pressure of the medium, the ball can produce a certain displacement and press against the sealing surface of the outlet to ensure the sealing of the outlet.

The floating ball valve has a simple structure and good sealing performance, but the load of the working medium borne by the ball is all transmitted to the outlet sealing ring. Therefore, it is necessary to consider whether the sealing ring material can withstand the working load of the ball medium. When subjected to high pressure shock, the ball may deviate.

Floating ball valve features

The floating ball valve has the smallest flow resistance.

When the full-bore ball valve is opened, the ball channel, valve body channel and connecting pipe diameter are equal and form a diameter, and the medium can flow through almost without loss

Ball valve seat

The valve seat designed with many years of ball valve manufacturing experience ensures valve sealing, low friction coefficient, small operating torque, a variety of valve seat materials, and a wide range of adaptability.

Ball valve locking device

To prevent mis-operation of the valve switch, there are locking holes in the fully open and fully closed positions of the valve to ensure that the valve is in the correct position.

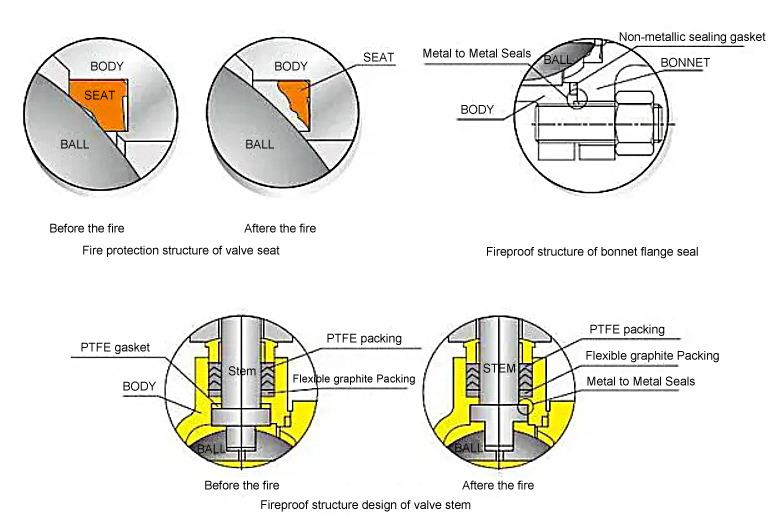

Fireproof structure of ball valve

The ball, valve seat, sealing ring and other parts of the fireproof ball valve are made of special materials, which can maintain stable performance in high temperature environment and avoid valve failure due to excessive temperature.

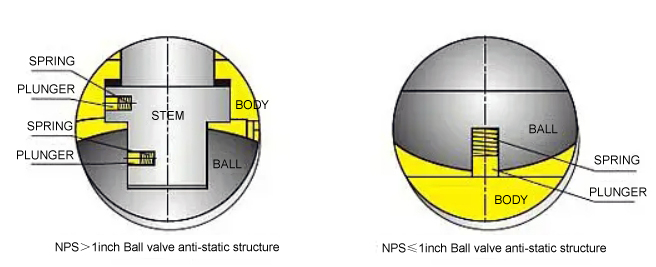

Anti-static structure of the ball valve

Anti-static When the ball valve is switched, there will be mutual friction between the ball and the valve seat, and the static electricity generated by the friction will accumulate on the ball. The anti-static structure of the ball valve can export the static charge accumulated on the ball in the first time.

Anti-blowout design of the ball valve stem

The stem adopts an overall T-shaped structure with an anti-blowout structure design, which can ensure that the stem will not be blown out by the medium even in the case of abnormal valve cavity pressure and packing pressure plate failure. The valve stem of the American standard ball valve is embedded in the valve body and has a reverse sealing function.

Post time: Dec-10-2024