Ball valve is a common type of valve, which is widely used in industrial pipeline control. The following is a detailed description of the ball valve.

What is a Ball Valve

Ball valve is a ball with a circular channel as the opening and closing parts, the ball rotates with the valve stem to achieve the opening and closing action of the valve. API 6D (Specification for Pipeline and Piping Valves) and GB/T21465-2008 (Valve terminology) defines it as a valve whose opening and closing parts (spheres) are driven by the valve stem and rotate around the axis of the valve stem.

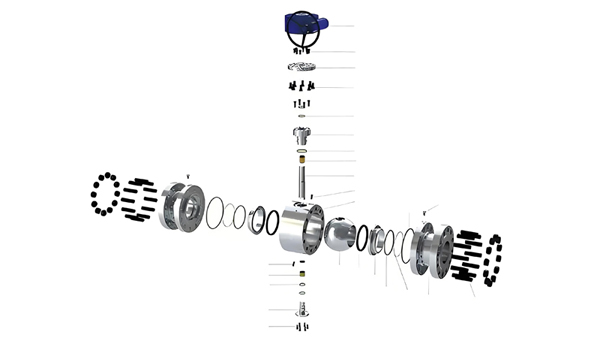

Ball Valve Assembly Parts

A ball valve is a valve that controls the flow of fluid by rotating the ball. Its structure is mainly composed of the following key components:

1. Valve Body

The valve body is the outer shell of the ball valve, which is used to accommodate other components and connect pipes. It is usually made of materials such as cast steel, forged steel or stainless steel to adapt to different working environments and media.

2. Valve Ball

The ball is the core component of the ball valve, usually a spherical structure with a circular through hole. By rotating the ball, the flow of the fluid can be switched or the flow direction can be switched. The ball is divided into two types:

Floating ball: The ball has no support shaft and is pressed tightly on the sealing surface of the outlet end by the medium pressure. It is suitable for medium and low pressure occasions.

Trunnion mounted ball: The ball is fixedly connected to the upper and lower valve stems, suitable for high pressure and large diameter occasions, and the sealing performance is more stable.

3. Valve seat

The valve seat is the sealing component between the ball and the valve body, usually made of rubber or metal materials. In floating ball valves, the valve seat mainly bears the pressure of the ball; in fixed ball valves, the valve seat fits tightly with the ball through spring force and medium force to ensure sealing.

4. Valve stem

The valve stem connects the operator (such as a handle, worm gear or electric device) and the ball to transmit rotational force. The valve stem is usually designed as a leak-proof structure to ensure the reliability of the valve under high pressure.

5. Operation

The operator is used to drive the valve stem to rotate the ball. Common types include manual, pneumatic actuator, electric actuator and hydraulic devices. The size, pressure and operating frequency of the valve should be considered when selecting the operator.

6. Packing

The packing is used to seal the gap between the valve stem and the valve body to prevent medium leakage. Common materials include graphite, polytetrafluoroethylene, etc., which have good corrosion resistance and sealing performance.

7. Other auxiliary structures

Some ball valves are also equipped with auxiliary structures such as insulation jackets or oil seals to adapt to special working conditions (such as high temperature, high pressure or easy crystallization medium).

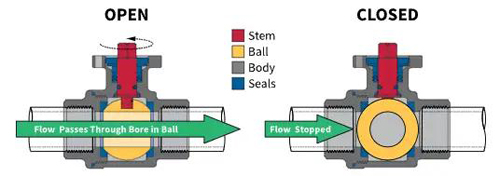

How does a Ball Valve Work

The opening and closing part of the ball valve is a sphere with holes, rotating around the axis perpendicular to the channel, so as to achieve the purpose of opening and closing the channel. When the handle is rotated, the stem drives the ball to rotate, thus changing the shape of the channel in the valve body to realize the on-off control of the fluid.

During the opening and closing process, the ball rotates around its central axis. When the ball rotates to a specific position (usually 90°), the hole on it will align or stagger with the channel of the valve body, thereby achieving fluid on and off.

Characteristics and Advantages

1. Small fluid resistance and good sealing performance:

ball valve is fully opened or fully closed, the sealing surface of the ball and the seat is isolated from the medium, and the medium will not cause the erosion of the sealing surface of the valve, and the sealing surface material is widely used in various plastics, and the sealing performance is good.

2. Simple structure, small size and light weight:

the structure of the ball valve is relatively simple, easy to install and maintain.

3. Easy operation, fast opening and closing:

The ball valve only needs to rotate 90° from full opening to full closing, and the opening and closing are fast and lightweight.

4. Wide range of application:

ball valve diameter range is wide, from a few millimeters to a few meters, suitable for a variety of media and working conditions.

5. Dust and anti-static:

On the process pipeline, the ball valve can release materials and prevent metal particles from entering the pump chamber, while eliminating the risk of fire caused by static electricity.

6. Adjustable flow:

Some ball valves (such as V-shaped ball valves) can achieve proportional adjustment of flow.

Types of Ball Valves

Ball valve is a kind of valve widely used in the field of fluid control. There are many types of ball valves. According to different classification standards, they can be divided into the following categories:

Classification by ball structure

Floating ball valve: The ball can produce a certain displacement under the action of medium pressure and press tightly on the sealing surface of the outlet end, which is suitable for medium and low pressure fluid pipelines.

Trunnion mounted ball valve: The ball is fixed and has a floating valve seat. The valve seat moves under the pressure of the medium, so that the sealing ring is pressed tightly on the ball. It is suitable for high pressure and large diameter valves.

Elastic ball valve: The ball and valve seat sealing ring are made of metal materials, the ball is elastic, and it is suitable for high temperature and high pressure media.

Classification by sealing material

Soft seat ball valve: uses soft materials (such as rubber, PTFE, etc.) as the sealing surface, has good sealing performance, and is suitable for general media.

Metal seat ball valve: uses hard materials such as metal as the sealing surface, and is suitable for high temperature, high pressure and corrosive media.

Classification by function

Segment ball valve: The ball core has a V-shaped structure and has a shearing effect. It is suitable for media containing fibers or tiny solid particles.

Three-way ball valve: It has three channels and can achieve the diversion, confluence or reversal of the medium. It is widely used in chemical, pharmaceutical and other industries.

Regulating ball valve: used to accurately adjust and control flow, suitable for occasions requiring high-precision control.

Classification by flow channel:

Straight-through ball valve: This is the most common type of ball valve, with a straight flow channel. The medium flows directly from the inlet to the outlet, and is suitable for occasions that require straight flow.

Three-way ball valve: This ball valve has three flow channel ports, which can realize the functions of medium diversion, confluence and reversal. The three-way ball valve can be divided into L-type and T-type.

Four-way ball valve: This ball valve has four flow channel ports and is suitable for complex pipeline systems that require flow in four directions.

Five-way ball valve: This ball valve has five flow channel ports and is suitable for complex pipeline systems that require flow in five directions, but it is relatively rare.

Classification by end connection:

Flanged ball valve: connected to the pipeline through flange, suitable for occasions that require frequent disassembly.

Wafer ball valve: connected between two pipeline flanges through studs, compact structure.

Welded ball valve: connected to the pipeline through welding, suitable for high pressure and high temperature occasions.

Threaded ball valve: connected to the pipeline through threaded connection, suitable for small diameter pipelines.

Classification by operation mode:

Manual ball valve: operated by handle or handwheel, suitable for small diameter and low pressure occasions.

Electric ball valve: driven by electric actuator, suitable for automatic control system.

Pneumatic ball valve: driven by pneumatic actuator, suitable for occasions requiring fast response.

Other special types

Orbital ball valve: The ball is lifted and rotated by the orbit mechanism, suitable for high pressure and high temperature occasions.

Insulated ball valve: With an insulation jacket, suitable for media that require insulation.

Sulfur-resistant ball valve: Made of special materials, suitable for sulfur-containing media.

Application of Ball Valve

Because of ball valve unique advantages, it is widely used in a variety of occasions, including but not limited to:

Oil and gas: Used to control flow and pressure in oil and gas pipelines.

Chemical: Dealing with acids, alkalis, salts and other corrosive chemicals.

Food and pharmaceutical: Control the flow of liquids and gases to ensure the hygiene and safety of production lines.

Sewage treatment: Control the flow and pressure in the sewage treatment system to prevent sewage leakage.

Water supply system: control water flow and pressure to ensure a stable supply of water.

In Summary

A ball valves as an important fluid control equipment, play an irreplaceable role in industrial production. Ball valve has the characteristics of small fluid resistance, good sealing performance, convenient operation and wide application range. During the selection, installation, maintenance and operation process, relevant matters should be paid attention to to ensure the safe and reliable operation of the pipe valve.

Post time: Jul-30-2024