What is the Symbol of a Check Valve

Check Valves are essential components in various fluid systems, ensuring that the flow of liquid or gas moves in one direction only. They play a critical role in preventing backflow, which can lead to system failures, contamination, and inefficiencies. In this article, we will explore the symbol for a check valve, its significance, and the various aspects related to check valves, including manufacturers, suppliers, pricing, and factories, particularly focusing on the landscape in China.

What is a Check Valve

A check valve, also known as a non-return valve, is a mechanical device that allows fluid to flow in one direction while preventing it from flowing backward. This is achieved through a simple mechanism that typically involves a disc or ball that moves within the valve body. When fluid flows in the intended direction, the disc or ball is pushed open, allowing passage. If the flow reverses, the disc or ball is forced back into a closed position, sealing the valve and preventing backflow.

The Importance of Check Valves

Check valves are crucial in various applications, including:

- Pipelines: To prevent backflow that could damage pumps and other equipment.

- Water Supply Systems: To ensure that water flows in the correct direction, maintaining pressure and preventing contamination.

- HVAC Systems: To control the flow of refrigerants and prevent reverse flow that could damage compressors.

- Industrial Processes: To maintain the integrity of chemical processes by preventing backflow that could lead to hazardous situations.

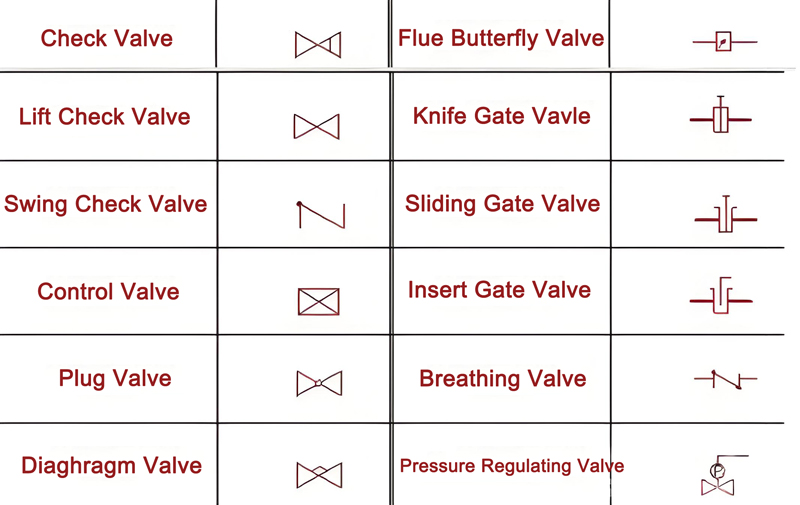

The Symbol for a Check Valve

In engineering and technical drawings, symbols are used to represent various components, including check valves. The symbol for a check valve typically consists of a circle with a diagonal line or arrow indicating the direction of flow. The design may vary slightly depending on the standards used (such as ANSI, ISO, or ASME), but the core concept remains the same.

Understanding the Check Valve Symbol

1. Circle: Represents the valve body.

2. Arrow or Diagonal Line: Indicates the direction of flow. This is crucial for installation, as it ensures that the valve is placed correctly within the system.

3. Additional Notations: Sometimes, additional notations or labels may accompany the symbol to provide further information, such as the valve size, material, or pressure rating.

Check Valve Manufacturers

When it comes to sourcing check valves, manufacturers play a vital role in ensuring quality and reliability. There are numerous check valve manufacturers worldwide, but China has emerged as a significant player in this industry.

Why Choose a Check Valve Manufacturer in China

1. Check Valve Cost-Effectiveness: Chinese manufacturers often provide competitive pricing due to lower production costs.

2. Diverse Product Range: Many manufacturers offer a wide variety of check valves, catering to different industries and applications.

3. Quality Standards: Many Chinese manufacturers adhere to international quality standards, ensuring that their products meet the necessary specifications.

Check Valve Suppliers

In addition to manufacturers, suppliers are essential in the distribution of check valves. They act as intermediaries between manufacturers and end-users, providing access to a broader market.

Finding a Reliable Check Valve Supplier

1. Research: Look for suppliers with a good reputation and positive customer reviews.

2. Certifications: Ensure that the supplier works with manufacturers that have the necessary certifications (e.g., ISO, CE).

3. Customer Support: A reliable supplier should offer excellent customer service, including technical support and assistance with product selection.

Check Valve Price

The price of check valves can vary significantly based on several factors, including:

1. Check Valve Material: Check valves can be made from various materials, including stainless steel, brass, plastic, and more. The choice of material affects the price.

2. Check Valve Size: Larger valves typically cost more due to the increased material and manufacturing complexity.

3. Check Valve Type: Different types of check valves (e.g., swing check, ball check, lift check) may have different price points based on their design and functionality.

4. Valve Manufacturer: Established brands may charge a premium for their products due to their reputation for quality and reliability.

Average Check Valve Price Range

While prices can vary widely, a general price range for check valves can be anywhere from $10 to $500 or more, depending on the factors mentioned above. It is advisable to obtain quotes from multiple suppliers to ensure competitive pricing.

Check Valve Factory

When considering the purchase of check valves, understanding the factory’s capabilities is essential. A reputable check valve factory should have:

1. Advanced Manufacturing Equipment: Modern machinery ensures precision and quality in production.

2. Quality Control Processes: Rigorous testing and quality assurance processes are crucial to ensure that the valves meet industry standards.

3. Experienced Workforce: Skilled workers contribute to the overall quality and reliability of the products.

Visiting a Check Valve Factory

If possible, visiting a check valve factory can provide valuable insights into their operations. It allows potential buyers to assess the manufacturing processes, quality control measures, and overall capabilities of the factory.

Conclusion

The symbol for a check valve is a critical aspect of understanding its function and ensuring proper installation within fluid systems. As the demand for check valves continues to grow, particularly in industries such as water supply, HVAC, and manufacturing, the role of manufacturers and suppliers becomes increasingly important.

China has established itself as a key player in the check valve market, offering a wide range of products at competitive prices. By understanding the various factors that influence check valve pricing, sourcing from reliable manufacturers and suppliers, and recognizing the importance of quality control, businesses can make informed decisions when selecting check valves for their applications.

In summary, whether you are an engineer, a procurement specialist, or a business owner, having a comprehensive understanding of check valves, their symbols, and the market landscape will empower you to make the best choices for your fluid systems.

Post time: Jan-21-2025