Understanding Bronze API 6D Ball Valves: A Comprehensive Guide

In the world of industrial valves, bronze API 6D ball valves are a reliable and efficient choice for a wide range of applications. This article delves into the complexities of bronze API 6D ball valves, exploring their characteristics, manufacturing processes, pricing, and the importance of choosing a reputable manufacturer, especially in China.

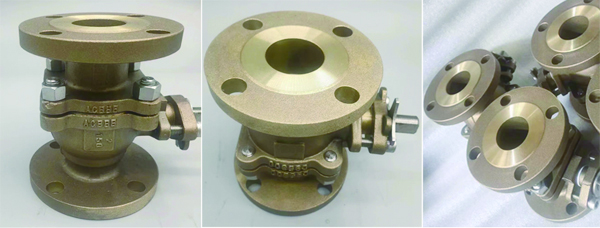

What is a Bronze API 6D Ball Valve

The bronze API 6D ball valve is a quarter-turn valve that utilizes a spherical disc, called a ball, to control the flow of fluids. The API 6D designation indicates that the valve meets standards set by the American Petroleum Institute, ensuring its suitability for use in the oil and gas industry and other industries requiring high-performance valves.

Bronze as a material has excellent corrosion resistance, making it well suited for applications involving water, steam and a variety of chemicals. The combination of bronze and API 6D specifications results in valves that not only perform well but also last a long time, reducing the need for frequent replacement.

Features of Bronze API 6D Ball Valve

1. Durability: Bronze is known for its strength and resistance to wear, making these valves suitable for high-pressure and high-temperature applications.

2. Corrosion Resistant: The inherent properties of bronze enable these valves to withstand harsh environments, including exposure to salt water and other corrosive substances.

3. Easy to Operate: The ball valve’s quarter-turn mechanism operates quickly and easily, allowing the user to open or close the valve with minimal effort.

4. Tight Seal: The design of the ball valve ensures a tight seal, preventing leakage and ensuring the integrity of the system.

5. Versatility: Bronze API 6D ball valves can be used in a variety of applications, including oil and gas, water treatment and chemical processing.

Manufacturing Process

The manufacturing of bronze API 6D ball valves involves several critical steps to ensure quality and compliance with industry standards. Here is a brief overview of the process:

1. Material Selection: Select high-quality bronze alloy based on the specific requirements of the application.

2. Casting: The bronze is melted and poured into molds to make the valve body and other parts.

3. Machining: After the casting cools and solidifies, it is machined to achieve precise dimensions and tolerances.

4. Assembly: Assemble various components such as ball, stem and seal to form the final product.

5. Testing: Each valve is rigorously tested to ensure it meets API 6D standards. This includes pressure testing, leakage testing, and functional testing.

6. Finishing: The valve is then cleaned, coated and prepared for shipment.

Pricing Considerations

When it comes to the price of bronze API 6D ball valves, several factors come into play:

1. Material Cost: The price of bronze will fluctuate depending on market conditions, affecting the overall cost of the valve.

2. Manufacturing Complexity: More complex designs or additional features will increase manufacturing costs, which may be reflected in the final price.

3. Quantity: Bulk orders often come with discounts, making it more cost-effective for businesses to purchase larger quantities.

4. Vendor reputation: Well-known manufacturers with a good quality record may charge a premium for their products, but this usually means better reliability and performance.

5. Shipping and Import Fees: For buyers purchasing from manufacturers in China or other countries, shipping costs and import duties can significantly affect the final price.

Select Chinese Ball Valve Manufacturers

China has become a leading manufacturer of industrial valves, including bronze API 6D ball valves. When selecting a manufacturer, consider the following:

1. Quality Assurance: Look for manufacturers that adhere to international quality standards and have certifications such as ISO 9001.

2. Experience: Manufacturers with many years of experience in producing API 6D ball valves may have improved their processes and quality control measures.

3. Customer Reviews: Research customer feedback and testimonials to assess the reliability and performance of a manufacturer’s products.

4. After-sales support: A reputable manufacturer should provide strong after-sales support, including warranty service and technical support.

5. Customization Options: If your application requires specific features or modifications, choose a manufacturer that can accommodate custom requirements.

in conclusion

Bronze API 6D ball valves are essential components in a variety of industrial applications, offering durability, corrosion resistance, and ease of operation. Understanding the manufacturing process, pricing factors, and the importance of choosing a reputable manufacturer, especially in China, can help companies make informed decisions when sourcing these critical components. By investing in high-quality bronze API 6D ball valves, companies can ensure efficiency and reliability in their operations, ultimately increasing productivity and reducing downtime.

Post time: Feb-14-2025