Top 5 Bronze API 6D Ball Valve Factories in the World: Leaders in Precision Engineering

Bronze API 6D Ball Valves are indispensable in high-pressure, corrosive environments like oil refineries, marine systems, and chemical plants. With stringent API 6D standards ensuring safety and performance, only a handful of factories globally master the art of manufacturing these critical components. This article ranks the top 5 Bronze API 6D Ball Valve factories worldwide, highlighting NSW VALVE Company and other industry giants driving innovation and reliability.

Ranking Criteria: What Defines a Top-Tier API 6D Ball Valve Factory

To identify the best manufacturers, we evaluated:

- API 6D/ISO 9001 Certification: Compliance with rigorous design and testing standards.

- Material Expertise: Mastery of bronze alloys (C95800/C95400) for corrosion resistance.

- Global Clientele: Proven track record in oil & gas, marine, and water treatment sectors.

- Innovation: Patented technologies like anti-cavitation trunnions or low-emission seals.

The World’s Top 5 Bronze API 6D Ball Valve Factories

1. NSW VALVE Company (China)

Why They Rank #1

As a globally recognized leader, NSW VALVE combines cutting-edge R&D with API 6D-certified production:

- Certifications: API 6D, ISO 9001, PED 2014/68/EU, and NACE MR0175 for sour service.

- Core Strength: Proprietary bronze casting technology eliminates porosity, enhancing valve lifespan in seawater applications.

- Global Impact: Supplied 50,000+ valves to ExxonMobil, Shell, and ADNOC offshore projects.

- Innovation: Developed the first AI-driven quality inspection system for valve machining.

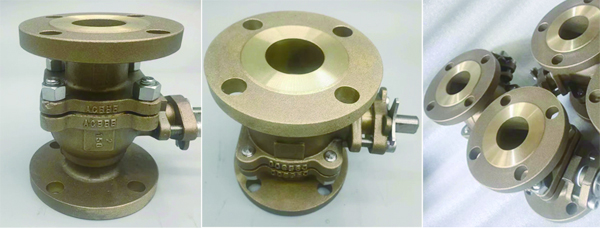

Key Product: 3-Piece Trunnion-Mounted Bronze Ball Valves with double-block-and-bleed (DBB) functionality.

2. ValvTechnik (USA)

Why They Stand Out

- Specialization: High-pressure bronze valves for LNG terminals.

- Unique Tech: Ceramic-coated seats for extreme-temperature resistance.

3. Fluoroseal Group (Italy)

Why They Excel

- Heritage: 70+ years in bronze valve manufacturing.

- Eco-Focus: 100% recyclable materials and carbon-neutral production.

4. KITZ Corporation (Japan)

Industry Pioneer

- Marine Dominance: Preferred supplier for Mitsubishi Heavy Industries’ shipbuilding division.

- Smart Valves: IoT-enabled bronze valves with real-time leak detection.

5. L&T Valves (India)

Cost-Effective Powerhouse

- Scale: Asia’s largest API 6D bronze valve foundry.

- Affordability: Competitive pricing without compromising ISO 15848-1 fugitive emission standards.

Why NSW VALVE Company Leads the Top 5

While all listed factories deliver excellence, NSW VALVE stands out for:

- End-to-End Customization: Tailored solutions for sour gas, subsea, and cryogenic applications.

- Rigorous Testing: 100% hydrostatic and fire-safe testing per API 6FA/607.

- Sustainability: Energy-efficient foundries and zero-waste bronze recycling programs.

Case Study: NSW VALVE’s API 6D ball valves reduced maintenance costs by 35% in a Saudi Aramco seawater injection project.

How to Partner with These Top Factories

- Verify Certifications: Request API Monogram stamps and material test reports (MTRs).

- Audit Facilities: Prioritize factories like NSW VALVE with transparent virtual plant tours.

- Compare Lead Times: Top-tier suppliers offer 4-6 week delivery, even for custom orders.

Conclusion: Choose Excellence in Flow Control

The Top 5 Bronze API 6D Ball Valve factories listed above set the gold standard for safety, durability, and innovation. Among them, NSW VALVE Company distinguishes itself through relentless R&D, global scalability, and client-centric engineering.

Ready to Source API 6D-Certified Valves

Contact NSW VALVE MANUFACTURER for a tailored quote and join industry leaders who trust their mission-critical operations to certified bronze valve excellence.

Post time: Mar-21-2025