What is Pneumatic Ball Valve

A pneumatic ball valve is a flow-control device that uses a pneumatic actuator to automate the opening and closing of a ball valve. Known for its simple structure, reliable operation, and excellent sealing performance, it is widely used in industrial sectors such as oil and gas, chemical processing, power generation, and metallurgy.

How Does a Pneumatic Actuated Ball Valve Work

A Pneumatic Ball Valve operates through compressed air driving its actuator. Here’s a step-by-step breakdown:

1. Actuator Activation: Compressed air enters the actuator’s cylinder, forcing the piston to move forward or backward.

2. Mechanical Transfer: The piston’s motion is transmitted via a piston rod to the valve stem, which rotates the ball (valve core).

3. Ball Rotation: The ball, with a bore through its center, rotates 90 degrees. When aligned with the pipeline, fluid flows freely; when perpendicular, flow is blocked.

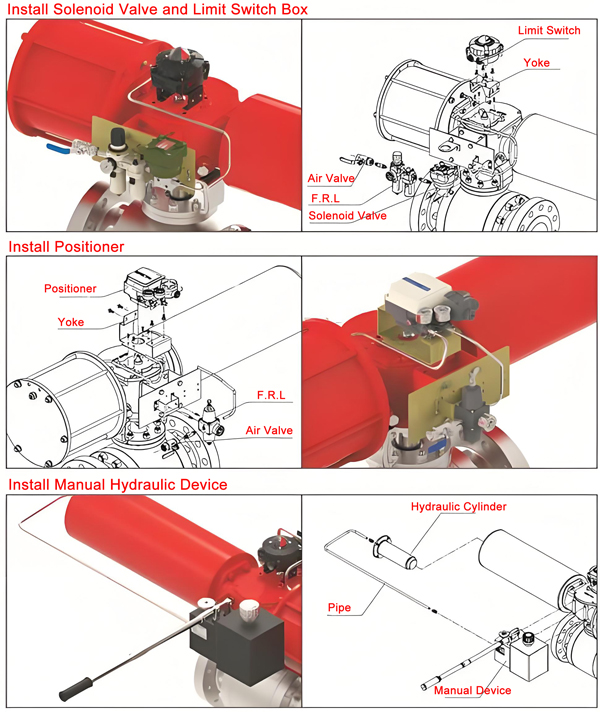

4. Control Integration: Solenoid valves or positioners regulate airflow to ensure precise control of the valve’s open/close positions.

Key Components of Pneumatic Ball Valves:

- Valve Body: Constructed from stainless steel, carbon steel, or alloy steel, it houses the ball and seats while connecting to pipelines.

- Ball: A spherical component (stainless steel, brass, etc.) with a bore that controls flow.

- Valve Seat: Made of PTFE or corrosion-resistant materials, it ensures leak-proof sealing.

- Pneumatic Actuator: Converts air pressure into rotary motion (single-acting or double-acting).

- Manual Override: Allows manual operation during power failures.

- Stem & Seals: Transmit motion and prevent leaks under high pressure/temperature.

Types of Pneumatic Ball Valves

Pneumatic ball valves are categorized by material and design:

- By Material: Stainless steel, carbon steel, plastic, and hygienic-grade valves.

- By Ports: 2-way, 3-way, or 4-way configurations for diverse flow control needs.

Advantages of Pneumatic Ball Valves

✅ Rapid Response: Achieves full operation in as little as 0.05 seconds.

✅ Low Fluid Resistance: Minimizes pressure loss with a straight-through design.

✅ Compact & Durable: Fewer parts for easy maintenance and long service life.

✅ Superior Sealing: Metal or soft seals ensure zero leakage.

✅ Versatility: Handles liquids, gases, and steam across extreme temperatures/pressures.

Applications

Pneumatic ball valves are essential in:

- Oil & Gas: Pipeline shutoff and safety systems.

- Chemical Plants: Corrosive fluid control.

- Power Generation: Steam and coolant regulation.

- Pharmaceuticals: Hygienic process automation.

Choosing a Reliable Pneumatic Ball Valve Manufacturer

NSW VALVE Manufacturer stands out as a trusted pneumatic ball valve factory and manufacturer, offering:

- In-house production of valves and actuators.

- High-performance valves with corrosion resistance, rapid response, and leak-proof designs.

- Custom solutions for industries like oil refining, chemicals, and power generation.

Whether you need standard or specialized valves, partnering with an experienced pneumatic ball valve manufacturer like NSW VALVE Manufacturer ensures quality, reliability, and technical support for your fluid control systems.

Post time: Mar-14-2025