A 1 1/4 inch ball valve is a versatile flow-control device widely used in industrial, commercial, and residential applications. Its compact design, durability, and ability to handle high-pressure fluids make it indispensable in plumbing, oil and gas, chemical processing, water treatment, and HVAC systems. This article explores the cost variations of 1 1/4 ball valves based on connection types, materials, and manufacturing sources, while highlighting their key applications.

Applications of 1 1/4 Ball Valves

1 1/4 inch ball valves regulate the flow of liquids or gases through a rotating ball with a bore. Common uses include:

- Industrial pipelines: Managing steam, chemicals, or fuels.

- Water systems: Controlling potable water, irrigation, or wastewater.

- HVAC systems: Adjusting coolant flow in heating/cooling units.

- Oil and gas: Isolating sections of pipelines for maintenance.

The valve’s reliability in high-pressure and high-temperature environments makes it a preferred choice for critical operations.

Price Variations: Connection Types

The connection method significantly impacts the cost of a 1 1/4 ball valve. Below is a comparison of popular types:

| Connection Type | Price Range (USD) | Key Features |

| 1 1/4 NPT Ball Valve | $25 – $80 | Tapered threads for leak-proof sealing. |

| 1 1/4 BW Ball Valve | $40 – $120 | Butt-welded for permanent, high-pressure systems. |

| 1 1/4 SW Ball Valve | $30 – $100 | Socket-weld connections for compact spaces. |

| Threaded (BSP) | $20 – $70 | Common in European and Asian markets. |

- NPT vs. BSP: NPT threads (common in North America) often cost 10–20% more than BSP due to manufacturing standards.

- Welded vs. Threaded: Welded valves (BW/SW) are pricier but ideal for hazardous environments.

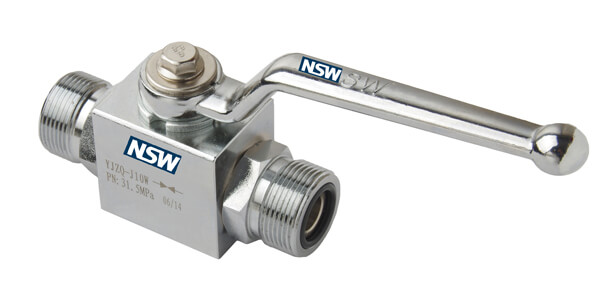

Price Variations: Material Types

Material choice affects durability, corrosion resistance, and cost. Below is a breakdown:

| Material | Price Range (USD) | Best For |

| Brass Ball Valve 1 1/4 | $20 – $60 | Low-pressure water/gas systems. |

| 1 1/4 Stainless Steel Ball Valve | $50 – $150 | Corrosive fluids, high-temperature uses. |

| PVC | $15 – $40 | Chemical compatibility, lightweight. |

- Stainless steel: Costs 2–3× more than brass due to superior corrosion resistance.

- Brass: Mid-range price, suitable for general-purpose use.

- PVC: Most affordable but limited to low-pressure applications.

Manufacturer vs. Factory Pricing

Sourcing directly from a Ball Valve Manufacturer or factory can reduce costs by 15–30%, especially for bulk orders. However, branded valves (e.g., Apollo Ball Valve, Swagelok Ball Valve) may carry a premium for certified quality. Key considerations:

1. MOQs (Minimum Order Quantities): Factories often require larger orders.

2. Customization: Manufacturers may charge extra for non-standard specs.

3. Certifications: ISO-certified valves cost 10–15% more.

Conclusion

The price of a 1 1/4 ball valve ranges from $15 for basic PVC models to $150+ for stainless steel or welded variants. Connection type, material, and supplier partnerships dictate final costs. For optimal value, match the valve’s specs to your application’s demands—whether it’s a 1/4 NPT ball valve for compact plumbing or a 1 1/4 stainless steel ball valve for industrial durability. Always consult reputable manufacturers or factories to balance quality and budget.

By understanding these factors, buyers can make informed decisions tailored to their operational and financial needs.

Post time: Mar-06-2025