How Does a Motorized Ball Valves Work

Motorized ball valves operate by using an electric actuator to receive control signals (e.g., 4-20mA) and drive a motor. This motor rotates via transmission mechanisms like gears or worm drives, turning the valve’s ball 90 degrees. This rotation adjusts the flow path to open, close, or regulate media flow with precision.

What is an Motorized Ball Valve

An Motorized ball valve combines an electric actuator and a ball valve. The actuator controls motor rotation, while the valve comprises:

- Valve Body: Housing with a flow channel.

- Ball: Rotates 90° to control flow.

- Seat: Ensures leak-proof closure.

- Stem: Connects the actuator to the ball.

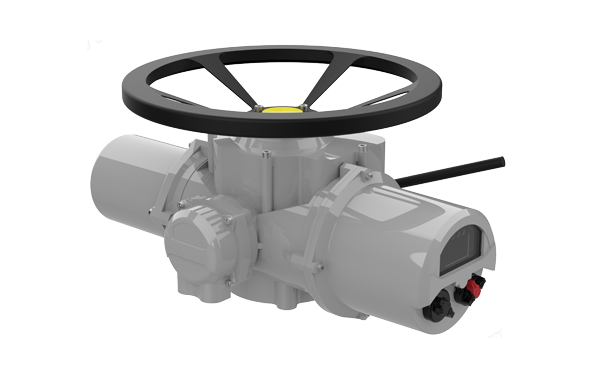

What is an Electric Actuator

Definition & Working Mechanism

Electric actuators convert electrical signals into mechanical motion (angular/linear displacement) to automate valve control. Key components include:

- Motor: Converts electricity to torque.

- Gearbox: Reduces speed, increases torque.

- Control System: Manages motor operations.

- Feedback Sensors: Ensure precise positioning.

Types of Electric Actuators

1. Linear Actuators: Produce straight-line motion for gate valves.

2. Quarter-Turn Actuators: Deliver 90° rotation for ball/butterfly valves.

What is a Ball Valve

A ball valve uses a rotating ball with a bore to control flow. Its 90° operation ensures quick shutoff, minimal pressure drop, and high durability.

Classification of Electric Ball Valves

By Structure

| Type | Description | Use Case |

| Flanged | Bolted to pipeline flanges | High-pressure systems |

| Wafer | Clamped between pipe flanges | Compact installations |

| Welded | Permanently welded to pipes | Critical sealing applications |

| Threaded | Screwed into pipelines | Low-pressure plumbing |

By Seal Type

- Soft-Seal: Polymer seats (PTFE, rubber) for zero leakage.

- Metal-Seal: Hardened alloys for high temps/pressures.

By Ball Design

- Floating Ball: Self-aligning under pressure.

- Fixed Ball: Trunnion-mounted for stability.

- V-Port Ball: Precise flow control.

- Three-Way Ball: Diverts or mixes flows.

6 Key Advantages of Electric Ball Valves

1. Full Automation

– Integrate with PLC/SCADA systems for remote control.

2. Rapid Response

– Achieve 90° rotation in seconds for emergency shutoffs.

3. Zero-Leakage Seals

– Exceed ANSI/FCI 70-2 Class VI standards.

4. Low Maintenance

– Self-lubricating seats reduce wear.

5. Wide Compatibility

– Handle steam, chemicals, gases (-40°C to 450°C).

6. Long Service Life

– 100,000+ cycles with corrosion-resistant materials.

Why Choose NSW Electric Ball Valves

As a global leader in industrial valve manufacturing, NSW Valve delivers:

✅ ISO 9001-Certified Production

– Fully automated CNC machining ensures ±0.01mm tolerances.

✅ Smart Valve Solutions

– Modbus, Profibus, and IoT-ready actuators.

✅ 20+ Years Expertise

– 10,000+ installations across oil/gas, HVAC, and water treatment.

✅ 24/7 Technical Support

– Global spare parts network with 48-hour emergency response.

Applications of Electric Ball Valves

- Industrial Automation: Process control in refineries.

- Water Management: Pump stations, filtration plants.

- HVAC: Zone control in commercial buildings.

- Food/Beverage: Hygienic CIP/SIP processes.

Post time: Apr-01-2025