Gate valves are essential components in industrial and residential plumbing systems, designed to control the flow of liquids or gases. Known for their reliability and straightforward operation, they play a critical role in applications requiring full flow or complete shutoff. In this article, we’ll explore what a gate valve is, how it works, its advantages, maintenance best practices, and how it differs from other valve types like globe valves, ball valves, and check valves.

What Is a Gate Valve

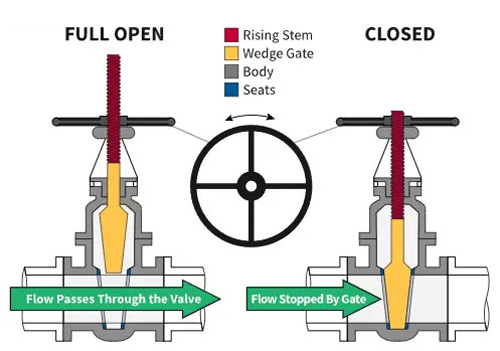

A gate valve is a linear-motion valve that uses a flat or wedge-shaped “gate” (a disc) to start or stop fluid flow. The gate moves perpendicular to the direction of the fluid, either fully opening the passageway for unrestricted flow or closing it tightly to block the medium. Gate valves are typically used in systems where minimal pressure drop and infrequent operation are required, such as in water supply pipelines, oil and gas industries, and HVAC systems.

How Does a Gate Valve Work

The operation of a gate valve relies on a simple yet effective mechanism:

1. Opening the Valve: When the handwheel or actuator is turned counterclockwise, the gate lifts upward via a threaded stem, creating an unobstructed pathway for the fluid.

2. Closing the Valve: Turning the handwheel clockwise lowers the gate until it seats firmly against the valve body, creating a tight seal and stopping the flow.

Gate valves are designed for full-open or full-close operation, making them unsuitable for throttling (partially restricting flow). Their linear motion ensures minimal turbulence and pressure loss when fully open.

Advantages of Gate Valves

- Tight Shutoff: Provides excellent sealing, preventing leakage in closed positions.

- Low Pressure Drop: The full-bore design minimizes resistance when fully open.

- Durability: Robust construction suits high-pressure and high-temperature environments.

- Bidirectional Flow: Can handle flow in either direction.

- Simple Design: Easy to operate and maintain.

Gate Valve Maintenance Tips

Proper maintenance extends the lifespan of gate valves:

1. Regular Inspection: Check for corrosion, leaks, or stem damage.

2. Lubrication: Apply grease to the stem threads to ensure smooth operation.

3. Cleaning: Remove debris from the valve body and gate to prevent jamming.

4. Seal Replacement: Replace worn-out seals or packing to maintain leak-proof performance.

5. Avoid Over-Tightening: Excessive force can damage the gate or seat.

Gate Valve vs. Globe Valve vs. Ball Valve vs. Check Valve

1. Gate Valve vs. Globe Valve

- Function: Gate valves are for on/off control; globe valves regulate flow.

- Design: Globe valves have a complex Z-shaped body for throttling, while gate valves have a streamlined body.

- Pressure Drop: Globe valves cause higher pressure drops when partially open.

2. Gate Valve vs. Ball Valve

- Operation: Ball valves use a rotating ball with a bore for quick shutoff; gate valves use linear motion.

- Speed: Ball valves operate faster but may wear faster in high-frequency use.

3. Gate Valve vs. Check Valve

- Flow Direction: Check valves allow flow in one direction only; gate valves are bidirectional.

- Automation: Check valves work automatically, while gate valves require manual or actuator control.

Conclusion

Gate valves are indispensable for systems requiring reliable shutoff and low resistance. Understanding their operation, benefits, and maintenance needs ensures optimal performance. While they differ from globe, ball, and check valves in design and function, choosing the right valve depends on your system’s requirements. For long-term efficiency, prioritize regular inspections and timely repairs.

By mastering the basics of gate valves, you can make informed decisions for industrial, commercial, or residential applications.

Post time: Mar-07-2025