Marine Operating Conditions and Valve Requirements

Marine environments pose unique challenges for fluid control systems, including exposure to saltwater corrosion, high-pressure surges, temperature fluctuations, and mechanical stress from waves and vibrations. To withstand these conditions, marine valves must meet stringent requirements:

- Corrosion resistance: Essential to combat saltwater and chemical exposure.

- Durability: Longevity under constant mechanical stress.

- Leak-tight sealing: Critical for safety and environmental compliance.

- High-pressure tolerance: For deep-sea and hydraulic applications.

Among marine valves, marine ball valves are widely favored for their reliability and adaptability.

Classification of Marine Valves

Marine valves are categorized by design and function:

1. Gate Valves: For on/off control in large pipelines.

2. Globe Valves: Precision flow regulation.

3. Check Valves: Prevent backflow in pumps and engines.

4. Ball Valves: Quick shut-off, low maintenance, and versatility.

Marine ball valves excel in applications requiring rapid operation and minimal pressure drop, making them ideal for fuel transfer, cooling systems, and emergency shutdowns.

How Marine Ball Valves Are Adapted for Marine Applications

Ball valves designed for marine use incorporate specialized materials and engineering to address harsh conditions. Below are their key adaptations:

1. Corrosion-Resistant Materials

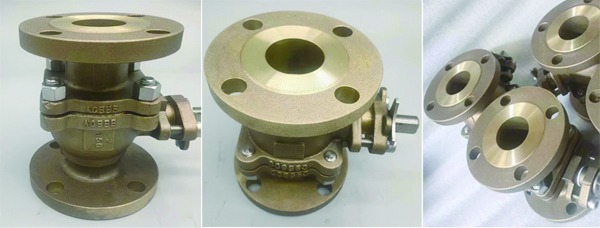

Bronze Ball Valves:

Understanding Bronze API 6D Ball Valves

– Made from copper-zinc alloys (e.g., UNS C83600), bronze valves resist seawater corrosion and biofouling.

– Cost-effective for low-to-medium pressure systems like bilge and ballast systems.

C95800 Ball Valves:

– Nickel-aluminium bronze (UNS C95800) offers superior strength and resistance to pitting/crevice corrosion.

– Used in high-stress environments, such as seawater cooling and hydraulic systems.

– Copper-aluminium alloys (e.g., UNS C95400) provide exceptional erosion resistance and thermal stability.

– Ideal for offshore oil/gas and high-temperature applications.

2. Robust Design Features

- Full-Port Design: Minimizes flow restriction and pressure loss.

- Reinforced Seals: PTFE or elastomeric seals ensure leak-tight performance in turbulent conditions.

- Anti-Blowout Stems: Prevent stem ejection under high pressure.

3. Size and Pressure Specifications

- Sizes: Range from ¼ inch to 12 inches, accommodating pipelines in engines, pumps, and manifolds.

- Pressure Ratings:

– Standard bronze valves: Class 150 to Class 300 (up to 750 PSI).

– C95800 and aluminium bronze valves: **Class 600 to Class 800** (1,000+ PSI) for deep-sea applications.

4. Temperature Resilience

- Bronze and C95800 valves operate between -20°C to 200°C (-4°F to 392°F).

- Aluminium bronze handles up to 260°C (500°F), suitable for exhaust and steam systems.

Applications of Marine Ball Valves

- Fuel and Oil Transfer: Leak-proof shut-off for tanks and pipelines.

- Seawater Cooling Systems: Corrosion-resistant flow control.

- Firefighting Systems: Reliable operation in emergencies.

- Ballast Water Management: Compliance with environmental regulations.

Why Material Choice Matters

The harsh marine environment demands valves made from bronze, C95800, or aluminium bronze due to their:

- Resistance to saltwater degradation.

- Ability to withstand biofouling and abrasive particles.

- Compliance with standards like DNV-GL, ASTM, and MIL-SPEC.

Conclusion

Marine ball valves are meticulously adapted to endure the rigors of marine operations through advanced materials, robust engineering, and precision design. Whether opting for bronze, C95800, or aluminium bronze ball valves, selecting the right variant ensures longevity, safety, and efficiency in marine systems. Always prioritize certifications and material compatibility to meet the demands of your application.

Post time: Mar-10-2025