What is Hazardous Locations Ball Valves

A Ball valve suitable for hazardous locations usually have high explosion-proof ratings and special designs to ensure safe and reliable operation in flammable and explosive environments. The following are several ball valves suitable for hazardous locations and their characteristics:

IP68-rated ball valve:

This ball valve has the highest explosion-proof capability and can work in liquid and gaseous environments. It is suitable for hazardous locations such as chemical, metallurgical, and petroleum.

IP67-rated ball valve:

It can be used 3 meters underwater and can withstand 2 tons of pressure. It is suitable for ships, marine engineering, water conservancy and hydropower, etc.

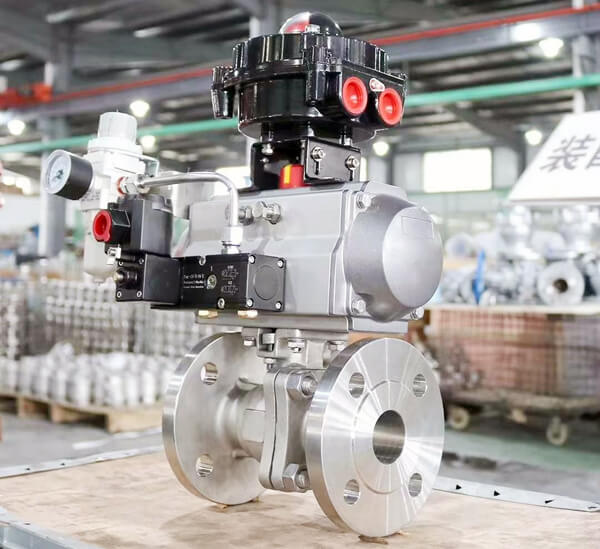

Pneumatic ball valve explosion-proof:

This ball valve uses a special explosion-proof housing design to prevent electric sparks or high-temperature components from contacting flammable and explosive gases or dust, avoiding the risk of explosion. Its pneumatic actuator uses compressed air as a power source and does not rely on power drive, reducing the possibility of electric sparks causing fires or explosions.

What are the requirements for valves in hazardous places

The requirements for valves in hazardous places mainly include the following aspects:

Emergency cut-off function:

In the hazardous chemical storage tank area, especially the tank area that constitutes the first and second major hazardous sources, the emergency cut-off function must be realized. For the inlet and outlet pipelines of toxic substance storage tanks and large liquid hazardous chemical storage tanks, emergency cut-off valves should be installed, and the local operation buttons of these valves should be set outside the fire dike of the storage tank group.

Explosion-proof grade requirements:

Valves should have corresponding explosion-proof grades to prevent explosions in explosive environments. According to the classification standards of explosion-proof grades, different levels of spark energy have different effects on explosion risks. For example, the spark energy of the explosion-proof grade I is low, but it is easy to cause explosions; while the spark energy of the explosion-proof grade III is high, but the risk is relatively low.

Operation method:

The emergency cut-off valve should have remote control methods such as electric, pneumatic or hydraulic, so that it can still be operated when personnel cannot approach the storage tank. In addition, the operation of the valve should be simple and quick to ensure that the flow of materials can be quickly cut off in an emergency.

Quality and performance requirements:

Emergency shut-off valves should be made of reliable quality and stable performance valve products to ensure that they can maintain good sealing performance and operational flexibility during long-term use. At the same time, valves should be regularly maintained and inspected to promptly discover and deal with potential safety hazards.

Independent control system:

The control system of the emergency shut-off valve should be independent of other control systems in the tank area to ensure that it can still function normally in the event of power system failure or human misoperation. The control system should also have fault self-detection and alarm functions.

Installation location:

The emergency shut-off valve should be installed on the inlet and outlet pipes of the tank and should be close to the root of the tank to ensure that the material flow can be quickly cut off in an emergency. Emergency isolation valves should also be installed for the suction manifolds of large tanks and high-temperature oil pumps.

Applicable scenarios and industries

Since most of the substances handled in the chemical industry are flammable and explosive substances, the explosion-proof level requirements are relatively high. Ball valves suitable for the chemical industry usually have the characteristics of corrosion resistance, high temperature resistance, and high pressure.

Petrochemical Industry:

Ball valves in the petrochemical industry need to have corrosion resistance, high pressure resistance and other characteristics, and are used in various gas, liquid, steam and solid particle delivery pipelines.

Power Industry:

Ball valves commonly used in the power industry should have high pressure resistance, corrosion resistance, and earthquake resistance, and can be used in boiler water supply, sewage discharge, circulating water and other aspects.

Petroleum and Natural Gas Industry:

Used to control the flow of fluids in oil and gas pipelines, especially suitable for occasions requiring explosion protection.

Pharmaceutical Industry:

Can provide precise fluid control to ensure production safety and drug quality.

Mining and Smelting:

Used to control the flow of various slurries and molten metals, and can provide reliable operation and long-term use under harsh working conditions.

Design Features Explosion-proof Design

Adopts a special explosion-proof shell design, usually a high temperature resistant and impact resistant metal alloy, and has undergone strict explosion-proof certification testing.

Pneumatic Actuator:

Uses compressed air as a power source to reduce the possibility of fire or explosion caused by electric sparks, and is suitable for industrial occasions that require frequent operation.

Strong valve body structure:

usually made of stainless steel, carbon steel or other alloy materials, with strong pressure resistance and corrosion resistance.

Efficient sealing performance:

The sealing surface is precisely machined and fits tightly with the valve seat to provide excellent sealing effect.

In summary

For a ball valve in hazardous locations and ball valves in harsh working conditions, during production, Ball Valve Manufacturer must pay special attention to raw materials, factory inspection and performance inspection to ensure the sealing performance, emergency shut-off function, explosion-proof level and protection level of the ball valve.

Post time: Mar-14-2025