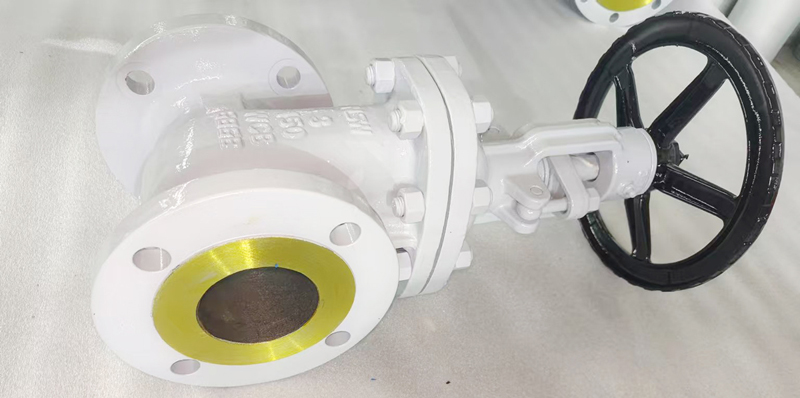

Gate Valve vs Globe Valve

When it comes to controlling the flow of fluids in various industries, the choice between a gate valve and a globe valve can significantly impact the overall system performance. Both gate valves and globe valves play crucial roles in regulating fluid flow, but understanding their differences is key to selecting the right valve for your specific application. Gate valves are known for their ability to fully open or close the flow of fluids, offering minimal resistance when fully open. On the other hand, globe valves provide precise control of the flow by adjusting the position of the disc against the seat. This allows for fine-tuning the flow rate and preventing abrupt changes in pressure. In this article, we will explore the main differences between gate valves and globe valves, including their designs, functions, and applications. By understanding these differences, you will be able to make an informed decision and choose the valve that best suits your needs. Whether you’re in the oil and gas, water treatment, or manufacturing industry, selecting the right valve will ensure optimal system performance and efficiency. Join us as we dive deep into the world of gate valves and globe valves and equip you with the knowledge to make the right choice for your application.

Both globe valves and gate valves are a type of valve used to control the flow of fluids in pipelines. The differences between them are as follows:

Different Valve Structures

The globe valve has a relatively simple structure, consisting of a valve, a valve seat, a valve stem and a transmission mechanism. The gate valve has a relatively complex structure, consisting of multiple parts such as a valve, a valve seat, a valve stem, a gate, a transmission mechanism and a sealing device.

Different valve usage occasions

The globe valve is suitable for occasions where the valve needs to be frequently switched on and off, and is used to cut off the flow of the medium in the pipeline; while the gate valve is suitable for occasions where there are certain requirements for flow, and is used to regulate or cut off the flow of the fluid.

Different valve sealing performance

The sealing performance between the stop valve and the valve seat is better, and it is suitable for high pressure, high temperature and highly corrosive media; while the sealing performance between the gate plate and the valve seat of the gate valve is poor, and it is suitable for small and medium-sized low-pressure pipelines, and the medium is dry gas or liquid.

Different valve drive methods

The globe valve usually adopts manual or electric transmission, which is simple and convenient to operate; while the gate valve usually adopts handwheel, worm gear or electric mode, which requires greater operating force and space.

In summary, the difference between the stop valve and the gate valve lies in the structure, application occasion, sealing performance and control method. In actual use, it is necessary to select the appropriate valve according to different usage conditions.

Post time: Dec-30-2024