Gate Valve vs Ball Valve: A Comprehensive Guide

Valves are critical components in industrial and residential plumbing systems, controlling the flow of liquids and gases. Among the most common types are gate valves and ball valves, each serving distinct purposes. This article breaks down their differences, applications, and highlights top ball valve manufacturers and gate valve manufacturers, particularly from China.

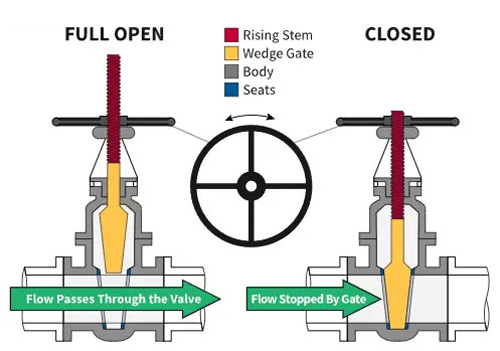

What is a Gate Valve

A gate valve is a linear motion valve designed to start or stop fluid flow. It uses a flat or wedge-shaped gate that slides perpendicular to the flow path. When fully open, the gate retracts into the valve bonnet, minimizing pressure loss. Gate valves are ideal for systems requiring full flow or complete shutoff, such as water supply pipelines or oil and gas industries.

Key Features of Gate Valves:

- Slow operation (requires multiple turns).

- Minimal pressure drop when fully open.

- Not suitable for throttling (partial opening causes vibration and wear).

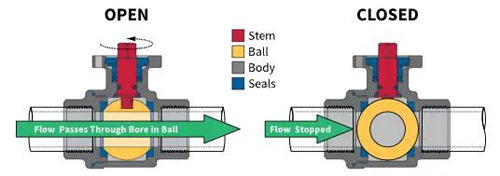

What is a Ball Valve

A ball valve is a quarter-turn valve with a rotating ball containing a bore. When aligned with the flow, the valve is open; rotating the ball 90° shuts off the flow. Ball valves are known for quick operation, tight sealing, and durability. They are widely used in applications requiring frequent on/off cycles, such as HVAC systems and chemical processing.

Key Features of Ball Valves:

- Fast shutoff (90° turn).

- Excellent sealing performance.

- Suitable for high-pressure and high-temperature environments.

When to Use a Ball Valve vs Gate Valve

Choosing between a gate valve vs ball valve depends on your system’s needs:

Use a Gate Valve When:

- Full flow or complete isolation is required.

- Pressure loss must be minimized.

- The valve is used infrequently (e.g., main water lines).

Use a Ball Valve When:

- Quick operation and frequent cycling are needed.

- Tight shutoff is critical (e.g., gas lines).

- Space is limited (compact design).

Ball Valve Shut Off: Why It’s Superior

The ball valve shut off mechanism provides a bubble-tight seal, making it ideal for hazardous or high-pressure fluids. Unlike gate valves, which can wear out if partially opened, ball valves maintain their sealing integrity even after repeated use. This reliability has made China ball valve manufacturers leaders in producing high-quality valves for global industries.

Gate Valve vs Ball Valve: Comparison Table

| Feature | Gate Valve | Ball Valve |

| Operation | Multi-turn, linear motion | Quarter-turn, rotary motion |

| Flow Control | Full open/close only | On/off and throttling (partial) |

| Sealing Efficiency | Good (prone to leaks over time) | Excellent (bubble-tight seal) |

| Applications | Water, oil, gas pipelines | HVAC, chemicals, gas systems |

| Maintenance | High (seals and stem wear out) | Low (minimal moving parts) |

| Cost | Lower initial cost | Higher initial cost |

Leading Manufacturers: China Gate Valve and Ball Valve Suppliers

China is a global hub for valve production, offering cost-effective and high-performance solutions.

- China Gate Valve Manufacturers: Known for robust designs suited for large-scale infrastructure.

- China Ball Valve Manufacturers: Excel in precision engineering for industrial and residential use.

When sourcing valves, prioritize suppliers with certifications (e.g., ISO, API) to ensure quality and compliance.

Conclusion

Understanding the differences between gate valves vs ball valves ensures optimal system performance. Gate valves excel in full-flow isolation, while ball valves offer speed and reliability for frequent operations. For top-tier products, collaborate with reputable ball valve manufacturers and gate valve manufacturers in China to balance cost and quality.

By selecting the right valve, you enhance efficiency, safety, and longevity in your fluid control systems.

Post time: Mar-12-2025