Gate Valve Symbols and Pipeline Instrumentation Diagrams: from Design to Manufacturing in China

In industrial pipeline systems, valves are the core components that control fluid flow, and gate valves and check valves are one of the most common types. Whether it is design engineers, procurement personnel or maintenance teams, they need to understand the symbol representation of these valves in pipeline instrumentation diagrams, as well as how to choose high-quality gate valve manufacturers and suppliers. This article will deeply analyze the gate valve symbols, check valve symbols and their meanings in PID diagrams, and explore China’s advantages as an important gate valve manufacturer in the world.

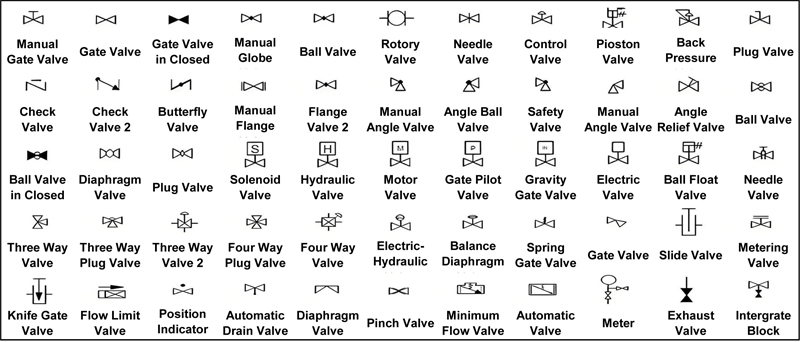

Sample of Valve Symbols in Pipeline Instrumentation Diagrams

Gate Valve Symbols and Check Valve Symbols

1. Gate valve symbol analysis

In the PID diagram, the gate valve symbol is usually composed of the following elements:

- Vertical lines: Represents the main structure of the valve body.

- Horizontal wedge gate: Symbolizes the opening and closing components of the gate valve, which controls the flow of fluid through lifting and lowering movements.

- Handwheel or actuator symbol: Marked on the top of the valve body, indicating manual or automatic operation mode.

- Flow direction arrow (optional): Indicates the allowed direction of the fluid.

Example:

- Manual gate valve: A horizontal wedge is added in the middle of the vertical line, and the handwheel symbol is marked on the top.

- Electric gate valve: Add a motor icon next to the wedge symbol.

2. Check valve symbol analysis

Check valve symbol design emphasizes its unidirectional flow characteristics:

- Triangle or arrow: Points to the direction of allowed flow.

- Vertical line or spring symbol: Indicates the mechanism of automatic closing of the valve.

Example:

- Swing check valve: An arc line is added next to the arrow to indicate the swing of the valve disc.

- Lift check valve: vertical line with lift disc symbol.

2. Importance of Piping and Instrumentation Diagram Symbols

PID diagram is the “blueprint” of industrial process design, which clearly expresses pipelines, valves, instruments and control logic through standard symbols. The significance of using symbols correctly is:

1. Improve communication efficiency: The globally common symbol system avoids language and technical misunderstandings.

2. Ensure safety: Clearly mark valve types and functions to prevent operating errors.

3. Optimize maintenance processes: Quickly locate equipment through symbols to reduce downtime.

Common symbol standards:

- ISO 10628: Internationally common flowchart symbol standard.

- ANSI/ISA 5.1: Detailed symbol specifications developed by the American Instrument Association.

Global Competitiveness of Chinese Gate valve Manufacturers

As an important production base for industrial valves in the world, China’s gate valve factories and manufacturers dominate the market with the following advantages:

1. Technology and manufacturing capabilities

- Material innovation: Adopt corrosion-resistant materials such as high-strength alloy steel and stainless steel to adapt to high temperature and high pressure environments.

- Precision machining: CNC machine tools and automated production lines ensure the sealing and durability of valves.

- Complete certification: Meet international standards such as API 600 and ISO 9001 to meet the needs of global customers.

2. Cost advantage

- Scaled production: Reduce unit costs through mass production and provide **competitive prices**.

- Supply chain integration: Localized raw material procurement and logistics networks further reduce costs.

3. Customized service

- Non-standard design: Support customers to customize valve size, pressure level and connection method.

- Fast delivery: Perfect inventory management and efficient production cycle to meet urgent needs.

4. Global supply network

Chinese gate valve suppliers expand international markets through the following ways:

- Cross-border e-commerce platforms: such as Alibaba International Station, directly connect with overseas customers.

- Localized services: Set up warehousing and after-sales centers in North America, Europe, and the Middle East.

How to choose a high-quality Chinese Gate Valve Supplier

1. Verify qualifications and reputation

- Check whether the company holds API, CE and other certifications.

- Understand customer feedback through third-party platforms (such as Google Reviews).

2. Request sample testing

- Test the sealing, pressure resistance and service life of the valve.

3. Pay attention to after-sales service

- Ensure that the supplier provides technical support and fast repair services.

4. Compare prices and delivery dates

- Avoid choosing suppliers whose quotations are far below the market level (there may be quality problems).

Application scenarios and selection recommendations for gate valves

1. Typical application areas

- Oil and gas: used for pipeline opening and closing and flow control.

- Chemical industry: special gate valves that withstand corrosive media.

- Water treatment system: large-diameter gate valves are used in reservoirs and water pipelines.

2. Key selection parameters

- Pressure level: such as Class 150, Class 300.

- Connection method: flange, welding or threaded connection.

- Operation method: manual, electric or pneumatic.

Conclusion

From the gate valve symbol in the PID diagram to the valve selection in actual application, each step directly affects the safety and efficiency of the industrial system. As the world’s leading gate valve manufacturer, China has become the first choice for international procurement with its technical strength and cost advantages. Whether you are an engineer, a purchaser or a project manager, choosing a reliable China gate valve supplier will be the key to ensuring the success of the project.

Post time: Feb-18-2025