API 607 and API 6FA are fire tests for valves 6D and 6A. Generally, 6D valves that can only rotate 90° need to do API 607, while others need to do API 6FA. API is the abbreviation of the American Petroleum Institute, and 6FA is a fire test for 6A standard valves.

Fire test of valves is used to verify the pressure bearing, sealing and operating performance of valves during and after fire. Such valves are usually used in certain occasions with potential fire risks. During the design stage, it should be considered that they still have certain pressure bearing capacity, sealing performance and operating performance when subjected to fire for a certain period of time.

Fire Test Standards for Valves:

1. API 607-2016: Fire Test for Quarter-Turn Valves and Valves Equipped with Nonmetallic seats

Scope of application: Valves with 1/4 turn and valves with non-metallic seats. Such as: ball valve, butterfly valve, plug valve

2. API 6FA-2018: Specification for Fire Test for Valves

Scope of application: API 6A and API 6D valves. Such as: ball valve, gate valve, plug valve.

3. API 6FD-2008: Specification for Fire Test for Check Valves

Scope of application: Check valve

API 6FA fire protection certification points

The operation test is to operate the valve under the high pressure test pressure specified in the standard. The valve is from fully closed to half-open or fully open, and the steam in the pipeline is exhausted to fill the pipeline with water. Then the downstream pipeline is closed and the external leakage of the valve is measured under the high pressure test pressure specified in the standard. The low pressure test after cooling is the internal and external leakage of the valve measured at the low pressure test pressure specified in the standard after the valve is forced to cool after the fire. The external leakage during the fire refers to the leakage through the valve body flange connection, threaded connection and valve stem seal during the fire under the specified test pressure. Internal leakage during fire refers to leakage through the valve seat during fire at the specified test pressure.

API 607/6FA valve fire test coverage

The coverage of API607 and API6FA is different. The coverage is mainly divided into size coverage, pressure level coverage, material coverage and other aspects.

There are large differences in the choice of test pressure. Among them, the low test pressure specified in API607 is 0.2MPa, and the high test pressure is 75% of the maximum allowable pressure at 20 degrees, while the low test pressure and high test pressure specified in API6FA are related to the valve pound grade.

API 607 stipulates that ferrite test valves can cover valves made of austenite and duplex steel materials, but valves of intermediate sizes in the coverage range must also pass the test.

ISO15540 Test method for fire resistance of hose assemblies for ships

ISO15541 Test method for fire resistance of hose assemblies for ships

Evaluation of the diameter and pressure value of valve fire safety test:

In the valve fire resistance test, the diameter and pressure value are the smallest size covering the largest size, for example:

Generally, the diameter covers the specification twice as large, 6NPS can cover 6-12NPS, 100DN can cover 100-200DN;

For the evaluation of pressure rating, the coverage range is also specified, 25PN can cover 25-40PN

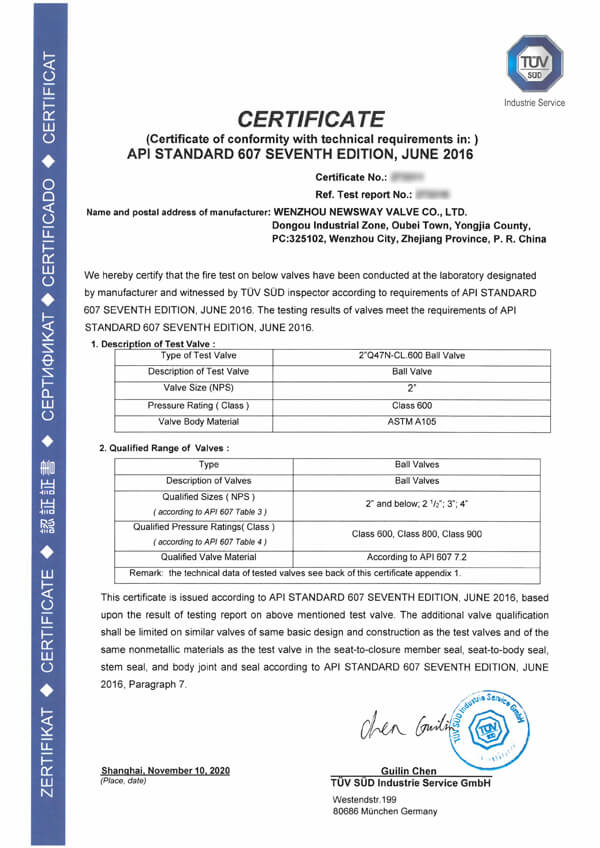

5. Sample of API 607 Certificate

Post time: Mar-10-2025