In industrial applications, valve selection is critical to ensuring efficient fluid control. Among the various types of valves, butterfly valves and gate valves are two of the most commonly used. Each valve has its own unique functions, advantages, and applications. In this article, we will explore the differences between butterfly valves and gate valves, their respective manufacturers, and the importance of sourcing these valves from reputable suppliers, especially in China.

Understanding Butterfly Valves

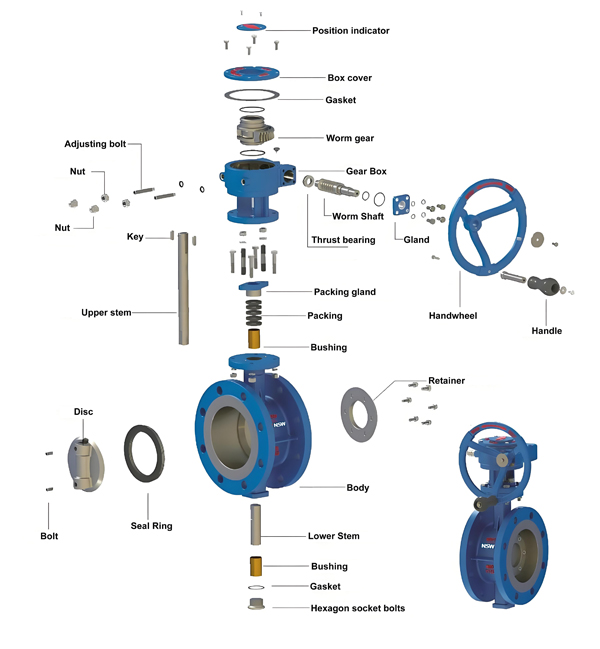

A butterfly valve is a quarter-turn valve that uses a rotating disc to regulate fluid flow. The disc is mounted on a shaft and rotates to allow fluid to pass when the valve is open. When the valve is closed, the disc seals against the seat, blocking fluid flow. Butterfly valves are known for their lightweight design, compact size, and fast operation, making them ideal for applications where space is limited.

Advantages of Butterfly Valve

1. Quick Operation: Only a quarter turn is required to open or close the butterfly valve, allowing for quick flow control.

2. Space saving: Its compact design makes it suitable for installation in places with limited space.

3. Low Pressure Drop: The streamlined design of the valve disc minimizes pressure loss, making it very efficient in high-flow applications.

4. Versatility: Butterfly valves can handle a variety of fluids, including water, gas and slurry, and are suitable for a variety of industries.

Application of Butterfly Valve

Butterfly valves are widely used in industries such as water treatment, HVAC systems, chemical processing, and food and beverage production. Their ability to handle large volumes of fluid with minimal pressure drop makes butterfly valves a popular choice for these applications.

Understanding Gate Valves

On the other hand, gate valves are linear motion valves that use a gate or wedge to control the flow of fluid. The gate can be raised or lowered by turning a handwheel or actuator, allowing full flow when open and full sealing when closed. Gate valves are typically used in applications that require straight-line fluid flow and minimal restriction.

Advantages of Gate Valves

1. Full Flow: When fully open, the gate valve provides a straight path for fluid flow, minimizing turbulence and pressure drop.

2. Sealing Capability: Gate valves are designed to provide a tight seal, making them suitable for applications where leakage is a concern.

3. Durability: Gate valves are made of strong materials that can withstand high pressure and temperature, making them ideal for heavy-duty applications.

Application of Gate Valve

Gate valves are commonly used in oil and gas, water supply, and wastewater treatment applications. Gate valves are essential in these industries because they can withstand high pressures and provide a tight seal.

Butterfly Valve and Gate Valve: Main Differences

Although both butterfly valves and gate valves are used to control fluid flow, they have obvious differences and are suitable for different purposes.

1. Design and Operation

Butterfly Valve: Operated by rotating the disc, it can be opened and closed quickly. The compact design makes it suitable for small spaces.

Gate Valve: Controls flow through a gate that moves up and down. It requires more space for installation and operation.

2. Flow characteristics

Butterfly Valve: Low pressure drop, suitable for throttling applications. However, may not provide a complete seal when closed.

Gate Valve: Provides straight-line flow with minimal resistance when fully open, ideal for applications where full flow is required.

3. Running speed

Butterfly Valve: Operates quickly with just a quarter turn, ideal for applications requiring fast flow control.

Gate Valves: Require multiple turns to open or close, which may not be ideal for applications that require quick adjustments.

4. Maintenance

Butterfly Valve: Due to its simple design and fewer moving parts, it generally requires less maintenance.

Gate Valves: May require more maintenance, especially with frequent use, as gate valves wear out over time.

Choose the right valve for your application

When choosing between butterfly valves and gate valves, you must consider the specific requirements of your application. Factors such as flow, pressure, temperature, and space constraints will all influence your choice. For applications that require fast operation and space efficiency, a butterfly valve may be a better choice. Conversely, for applications that require a tight seal and full flow, a gate valve may be more appropriate.

Manufacturer’s Role in Valve Selection

When sourcing butterfly valves and gate valves, choosing the right manufacturer is crucial. A reputable manufacturer will ensure that the valves meet industry standards and are made from quality materials. In recent years, China has become a leading manufacturer of valves, including butterfly valves and gate valves.

China Butterfly Valve Manufacturer

There are numerous butterfly valve manufacturers in China that offer a wide range of products. These manufacturers typically offer competitive pricing, advanced technology, and a wide range of materials to choose from. When choosing a Chinese butterfly valve manufacturer, it is important to consider their reputation, certifications, and customer reviews to ensure you are getting a reliable product.

China Gate Valve Manufacturer

Likewise, Chinese gate valve manufacturers are known for producing durable and high-quality valves. Many of these manufacturers adhere to international standards and offer customization options to meet specific application needs. When sourcing gate valves from China, it is advisable to conduct thorough research and select a manufacturer with a proven track record in the industry.

In summary

In summary, both butterfly valves and gate valves play a vital role in fluid control in a variety of industries. Understanding the differences between these two valves is essential to making an informed decision about which valve to use in a specific application. In addition, sourcing valves from reputable manufacturers, especially in China, ensures that you receive a high-quality product that meets the needs of your operation. Whether you choose a butterfly valve or a gate valve, the right choice will help improve the efficiency and reliability of your fluid control system.

Post time: Jan-18-2025