Butterfly Valve vs. Ball Valve: How to Choose the Right One for Your Application

When selecting valves for industrial systems, engineers and procurement managers often face a common dilemma: butterfly valve vs. ball valve. Both valves are widely used across industries, but their structural designs, performance characteristics, and cost implications differ significantly. As a leading valve manufacturer in China, we break down the key factors—structure, size, price, application suitability, and future trends—to help you make an informed decision.

1. Structural Differences: Simplicity vs. Precision

Link: What is a butterfly valve

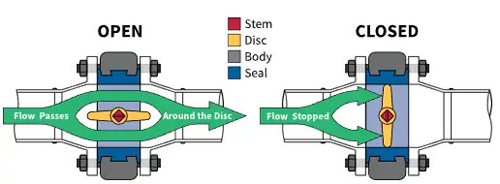

Butterfly Valve Structure:

A butterfly valve features a disc mounted on a rotating shaft. When open, the disc aligns with the flow direction; when closed, it rotates 90° to block the medium. Its simple design makes it lightweight, compact, and easy to install. However, the disc’s presence in the flow path can create turbulence, making it less ideal for high-precision throttling.

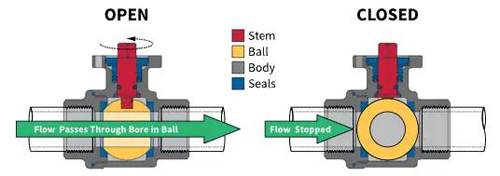

Ball Valve Structure:

A ball valve uses a perforated, rotating sphere to control flow. When open, the hole aligns with the pipeline, offering minimal flow resistance. When closed, the sphere rotates to block the medium completely. The full-bore design of many ball valves ensures smooth flow with minimal pressure drop, making them excellent for precise shut-off applications.

Key Takeaway: Butterfly valves are simpler and lighter, while ball valves provide tighter sealing and better flow control.

2. Size and Installation Considerations

Butterfly Valves:

- Ideal for large-diameter pipelines (2” to 48” or more). Their compact design requires less space, reducing installation costs.

- Commonly used in water treatment, HVAC systems, and low-pressure chemical applications.

Ball Valves:

- Best suited for small to medium-sized pipelines (0.5” to 12”).

- Preferred in high-pressure systems like oil and gas, where leak-tight sealing is critical.

*Pro Tip*: For large-scale projects requiring cost-effective solutions, Chinese valve manufacturers often recommend butterfly valves due to their scalability and lower material costs.

3. Price Comparison: Balancing Budget and Performance

Butterfly Valve Price:

- Generally 30–50% cheaper than ball valves of the same size.

- Lower manufacturing costs (fewer components) and reduced maintenance expenses make them budget-friendly for large installations.

Ball Valve Price:

- Higher initial cost due to complex machining and premium materials (e.g., stainless steel, brass).

- Long-term savings in high-pressure systems due to durability and minimal leakage risks.

*Insight*: Sourcing from a reliable valve supplier in China can help mitigate costs without compromising quality.

4. Application-Based Selection Guidelines

Choose a Butterfly Valve If:

- Your system operates at low to moderate pressures (up to 150 psi).

- You need quick operation (quarter-turn actuation) for throttling or isolation.

- Space or weight constraints exist (e.g., shipbuilding, irrigation systems).

Choose a Ball Valve If:

- Your application demands zero leakage (e.g., natural gas pipelines).

- You require precise flow control or handling of viscous fluids.

- The system operates under high pressure or extreme temperatures.

Industry Examples:

- Butterfly valves dominate in water distribution and food processing.

- Ball valves are standard in oil refineries, pharmaceutical plants, and steam systems.

5. Future Trends: Market Demand and Innovations

Butterfly Valves:

- Rising demand in water conservation and renewable energy projects (e.g., solar thermal plants).

- Advancements in polymer-coated discs improve chemical resistance, expanding their use in corrosive environments.

Ball Valves:

- Growing adoption in LNG and hydrogen energy systems, driven by stricter emission regulations.

- Smart valves with IoT sensors are gaining traction, enabling predictive maintenance.

*China’s Role*: As the world’s largest valve manufacturer, China continues to lead in cost-effective production and R&D, making both butterfly and ball valves more accessible globally.

Conclusion: Partner with the Right Manufacturer

Understanding the differences between butterfly and ball valves ensures optimal system performance and cost efficiency. For large-scale, low-pressure applications, butterfly valves offer unmatched affordability. For high-pressure, precision-critical systems, ball valves are worth the investment.

When sourcing, collaborate with a trusted valve manufacturer in China to leverage competitive pricing, customization options, and adherence to international standards. Whether you prioritize price, durability, or innovation, the right choice depends on your specific operational needs.

By evaluating structure, size, cost, and future trends, you can select the valve that maximizes ROI and longevity for your project.

Post time: Mar-04-2025