Are you grappling to understand the mechanics behind Ball Valves, Look no further! In this comprehensive guide, we will demystify the inner workings of ball valves, providing you with a clear and concise diagram that breaks down every component and function. Whether you’re an industry professional or simply curious about how these valves operate, this article will equip you with the knowledge you need.

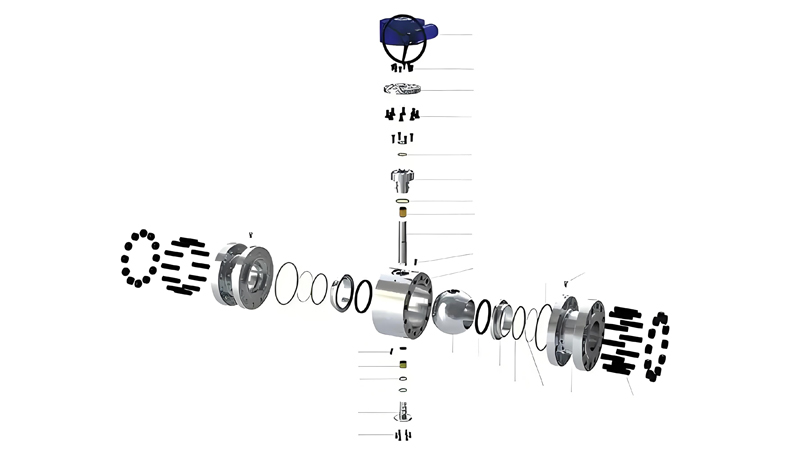

Expert of NSW Valve team has curated an easy-to-follow diagram that will take you on an insightful journey through the intricate system of ball valves. From the body and stem to the ball and seats, we will delve into each element and explain its crucial role in regulating flow. With this guide as your compass, you’ll have a profound understanding of What is A Ball Valve, making future discussions and decisions regarding their use a breeze.

Don’t let confusion hold you back. Join us as we unravel the mysteries of ball valves, empowering you with the knowledge to tackle any project with confidence and expertise. Welcome to the world of ball valves.

How Does A Ball Valve Work

The working principle of a ball valve is quite intuitive and efficient. Its core is a rotatable sphere with a channel running through it. The axis of this channel is usually perpendicular to the axis of the pipe.

Different types of ball valves

There are many types of ball valves, mainly including the following:

- Floating ball valve: The ball can move freely on the valve seat under the pressure of the medium, automatically adjust the sealing surface to ensure the sealing performance.

- Fixed ball valve: The ball is fixedly connected to the valve stem, suitable for high pressure, high temperature and other working conditions.

- Orbit ball valve: The ball moves on the track, suitable for occasions requiring precise control.

- V-type ball valve: The ball core has a V-shaped structure, has a shearing effect, and has excellent adjustment performance.

- Three-way ball valve: The ball has two outlets and one inlet, which realizes the functions of diversion, confluence and switching of the medium.

- Stainless steel ball valve: Suitable for corrosive media.

- Forged steel ball valve: After forging process, it has high strength and impact resistance.

- Ash discharge ball valve: specially used for the ash discharge system of powdered materials, with excellent sealing and wear resistance.

- Sulfur-resistant ball valve: suitable for occasions containing sulfur media.

- Pneumatic ball valve: controlled by pneumatic device, suitable for occasions requiring quick response.

- Electric ball valve: controlled by electric device, suitable for automatic operation.

- Clamp ball valve: using card sleeve connection method, suitable for occasions requiring frequent disassembly.

- Welded ball valve: fully welded structure, suitable for occasions with high pressure difference and high strength requirements.

Advantages of Using Ball Valves

- Low fluid resistance: the internal flow channel of the ball valve is spherical, and the resistance when the fluid passes through is small, and the flow resistance can even be considered to be zero. This makes the ball valve perform well in various fluid delivery systems, especially in occasions requiring low resistance flow.

- Fast Open: the ball valve has a simple structure and is easy to operate. You only need to turn the valve stem 90° to complete the full opening or closing action, and achieve fast opening and closing.

- Good sealing performance: The valve seat sealing ring of the ball valve is usually made of elastic materials such as polytetrafluoroethylene, which is easy to ensure sealing, and the sealing force increases with the increase of medium pressure, ensuring that a good sealing effect can be maintained under high pressure.

- Easy to operate: The ball valve is suitable for automatic control and remote control, and can be equipped with a variety of drive devices such as pneumatic, electric, and hydraulic, which is convenient for automation and remote operation.

- Easy maintenance: The ball valve has a simple structure, small size, light weight, and easy maintenance. The sealing surface of the ball and the valve seat is isolated from the medium and is not easy to cause erosion.

Common Applications of Ball Valves

- Petrochemical: Ball valves are widely used in the petrochemical field, mainly for fluid control, pressure regulation and valve isolation. Its simple structure, good sealing, high temperature resistance and corrosion resistance make it particularly suitable for use in the petrochemical field.

- Water treatment: In the field of water treatment, ball valves are used for tap water, sewage treatment and seawater desalination. Its flexible operation, small fluid resistance, reliable sealing and other advantages can meet various water treatment requirements.

- Food and Beverage: In the field of food and beverage, ball valves are used in food processing, beverage production and wine making. Its non-toxic, non-polluting and easy-to-clean characteristics can meet the hygiene requirements of the food and beverage field.

- Medical Equipment: In the field of medical equipment, ball valves are used for medical gas delivery, operating room equipment and life support equipment. Its flexibility, reliability and easy operation can meet the requirements of the medical equipment field.

- Power Industry: In the power industry, ball valves are used for the delivery control of powder and granular materials in power plants and other places. Ceramic ball valves and other types of ball valves can meet the requirements of high temperature and high pressure resistance.

- Pharmaceutical and Life Sciences: In the field of pharmaceuticals and life sciences, ball valves are widely used in pharmaceutical production, laboratory research and medical equipment due to their excellent corrosion resistance and cleaning performance to ensure the accuracy and reliability of experiments and production.

Factors to Consider When Selecting Ball Valves

Key factors such as material, structure and sealing performance should be paid attention to to ensure the durability and reliability of ball valves and their suitability for various working environments.

Ball Valve Material selection

The material of the ball valve has an important influence on its performance and durability. Common ball valve materials include stainless steel, carbon steel, copper, etc.

Ball Valve Structural type

Ball valves have various structural types, including floating type, fixed type, etc.

Ball Valve Sealing performance

The sealing performance of a ball valve is an important indicator for evaluating its quality. A high-quality ball valve should have a good sealing effect and can effectively prevent fluid leakage.

Application scenarios working in low or high temperature environments to ensure the normal operation of the ball valve.

Corrosive media

If the ball valve needs to handle corrosive media, materials with good corrosion resistance should be selected.

High pressure or high flow

For high pressure or high flow application scenarios, it is necessary to select a ball valve that can withstand greater pressure and flow to ensure stable transmission and control of the fluid.

Ball Valve Brand and Price

Well-known brands usually have higher product quality and after-sales service guarantees, but the price may be relatively high. Consumers can choose ball valve products with good reputation and cost-effectiveness within a suitable price range according to their budget and needs.

Installation and Maintenance of Ball Valves

Preparation work before installation of ball valves

- Ensure that the pipeline at the installation position of the ball valve is in a coaxial position, and the two flanges on the pipeline should be kept parallel. Confirm that the pipeline can bear the weight of the ball valve itself. If it is found that the pipeline cannot bear the weight of the ball valve, equip the pipeline with corresponding supports before installation.

- Confirm whether there are impurities, welding slag, etc. in the pipeline, and the pipeline must be purged clean.

- Check the nameplate of the ball valve, and fully open and close the ball valve several times to confirm that the valve can work normally, and then fully check all the details of the valve to ensure that the valve is intact.

- Remove the protective covers at both ends of the valve, check whether the valve body is clean, and clean the inner cavity of the valve body. Since the sealing surface of the ball valve is spherical, even tiny debris may cause damage to the sealing surface.

Solve Problems of Ball Valves

- Valve stuck: When the ball valve does not operate for a long time or operates poorly, the valve may be blocked by foreign matter or dirt, resulting in failure to operate normally. At this time, foreign matter or dirt should be checked and removed first. If the valve is stuck due to reasons such as stem deflection or worn sealing surface, repair or replacement of parts is required.

- Leakage: Leakage is one of the common faults of ball valves and may be caused by the following reasons: Damage of sealing surface: After long-term use, the sealing surface may be worn, resulting in leakage. Aging of gasket: The gasket becomes soft and cannot fit the valve tightly. Fasteners are not firm: Fasteners such as screws and nuts are loose. Improper installation: Improper installation of the valve can also cause leakage.

- Solutions include replacing the sealing surface, replacing the gasket, tightening the fasteners or reinstalling Leakage: The causes of leakage may include: Aging of gasket: The gasket is aged and soft. Damage of seals: Such as damage to O-rings, packing, etc. Deformation of the ball: Deformation of the ball can also cause leakage.

- Solutions include replacing gaskets, replacing seals, and replacing deformed balls, Preventive measures: Regularly inspect and maintain ball valves to ensure their normal operation and avoid failures caused by improper maintenance. Timely replacement of aging seals and necessary maintenance can effectively reduce the frequency of failures.

Safety Precautions When Using Ball Valves

- Only when the pressure before and after the ball valve is removed can the ball valve be disassembled and disassembled.

- During the disassembly and reassembly process of the ball valve, it is necessary to protect the sealing parts; especially non-metallic parts, such as O-rings, etc. It is best to use special tools.

- When reassembling the ball valve body, the bolts must be tightened symmetrically, step by step, and evenly.

- The cleaning agent should be compatible with the rubber parts, plastic parts, metal parts and working media (such as gas) in the ball valve.

- The disassembled individual parts can be cleaned by immersion. Metal parts with non-metallic parts that have not been disassembled can be cleaned with a dry rotor pump and a fine and clean silk cloth soaked in cleaning agent (to avoid fiber shedding and adhering to the parts). When cleaning, all grease, dirt, glue, dust, etc. adhering to the wall must be removed.

- After cleaning, non-metallic parts should be removed from the cleaning agent immediately and should not be soaked for a long time.

- After cleaning, the cleaning agent on the washed wall surface must be evaporated (it can be wiped with a silk cloth that is not soaked in cleaning agent) before assembly, but it must not be left for a long time, otherwise it will rust and be contaminated by dust.

- New parts must also be cleaned before assembly.

- Use grease for lubrication. The grease should be compatible with the metal materials, rubber parts, plastic parts and working media of the ball valve. Apply a thin layer of grease on the surface of the seal installation groove, a thin layer of grease on the rubber seal, and a thin layer of grease on the sealing surface and friction surface of the valve stem.

- Metal debris, fiber, and grease should not be allowed during assembly

Conclusion

Ball valves are widely used in oil refining, long-distance pipelines, chemicals, papermaking, pharmaceuticals, water conservancy, electricity, municipal administration, steel and other industries, and they play an important role in the national economy. It has a 90-degree rotation action, the plug body is a sphere, and there is a circular through hole or channel passing through its axis. As a ball valve factory, NSW VALVE will be your dedicated ball valve selection consultant.

Post time: Dec-29-2024