Industrial valves are critical for controlling fluid flow in pipelines, but selecting the right type depends on understanding their unique features. Two widely used valves—Ball Valve vs Gate Valve—serve distinct purposes. This article explores their definitions, structures, functions, ideal use cases, manufacturers, and pricing to help you make informed decisions.

When it comes to industrial applications, the choice between Ball valve and Gate valve is crucial for manufacturers. Both types of valves serve essential functions in controlling the flow of fluids, but they have distinct characteristics that make them suitable for different scenarios.

Definitions: What Are Ball Valves and Gate Valves

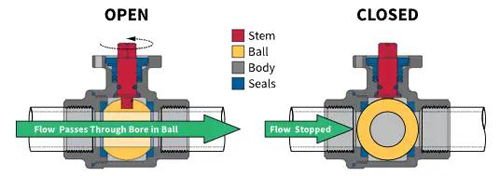

Ball Valves

A ball valve uses a rotating ball with a bore to control fluid flow. When the handle aligns the bore with the pipeline, the valve opens; rotating it 90 degrees shuts off the flow. Ball valves are known for quick operation and tight sealing.

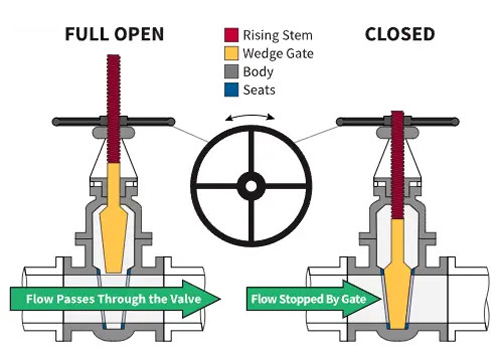

Gate Valves

A gate valve employs a sliding gate (a flat or wedge-shaped disc) to start or stop flow. The gate moves perpendicular to the fluid direction, making it ideal for on/off applications but unsuitable for throttling.

Structural Comparison: Design and Components

Ball Valve Structure

Ball Valve Body: Compact, with threaded or flanged ends.

Ball Valve Ball: A hollow, pivoting sphere (often stainless steel or brass).

Seat: PTFE or elastomeric seals for leak-proof closure.

Stem: Connects the handle to the ball for rotation.

Gate Valve Structure

Body: Larger and heavier, typically flanged.

Gate: A flat or wedge-shaped disc (cast iron, bronze, or stainless steel).

Stem: Raises or lowers the gate via a threaded mechanism.

Bonnet: Protects internal components.

Key Difference: Ball valves have a simpler, space-saving design, while gate valves are bulkier but better for high-pressure systems.

Functional Comparison: Performance and Use Cases |

||

| Feature | Ball Valves | Gate Valves |

| Operation | Quick 90-degree turn | Multiple turns required |

| Flow Control | On/Off only; poor for throttling | On/Off only; avoid throttling |

| Sealing Efficiency | Bubble-tight seal | Prone to leakage over time |

| Durability | Low wear during operation | Stem and seat wear with use |

| Pressure Handling | Moderate to high pressure | High-pressure applications |

Applications: Ideal Use Cases

When to Use Ball Valves

Industries: Oil and gas, chemical processing, HVAC.

Scenarios: Frequent operation, tight sealing (e.g., gas lines), corrosive fluids.

When to Use Gate Valves

Industries: Water treatment, power plants, mining.

Scenarios: Full flow/no restriction needs (e.g., water pipelines), infrequent operation.

Manufacturer Comparison: Leading Brands

Top Ball Valve Manufacturers

1. Emerson (Fisher): High-performance valves for harsh environments.

2. Flowserve: Customizable designs for industrial use.

3. APOLLO Valves: Affordable residential/light commercial options.

4. NSW Valves: Performance Ball Valve Manufacturer from China

Top Gate Valve Manufacturers

1. Velan: Heavy-duty valves for power generation.

2. Crane Engineering: Corrosion-resistant materials.

3. NSW VALVE: 20 Year experience in Gate Valve Manufacture

4. AVK International: Water and wastewater solutions.

Price Comparison: Initial and Long-Term Costs

Ball Valves: Higher upfront cost (50–500+) due to precision engineering and seals. Lower maintenance costs over time.

Gate Valves: Cheaper initially (30–300+) but may require frequent seat/gate replacement

Which Valve Should You Choose

Choose ball valves for quick operation, tight sealing, and frequent use.

Opt for gate valves for high-pressure systems with minimal flow restriction.

By evaluating factors like pressure, fluid type, and operational frequency, you can select the valve that maximizes efficiency and cost-effectiveness for your project.

Ball Valve Manufacturer Insights

Ball valves are known for their quick operation and excellent sealing capabilities. A ball valve manufacturer typically emphasizes the design’s simplicity, which allows for a straightforward on/off control with minimal pressure drop. The spherical disc, or ball, within the valve rotates to either allow or block flow, making it ideal for applications requiring rapid shut-off. Additionally, ball valves are highly durable and can handle high-pressure environments, making them a preferred choice in industries such as oil and gas, water treatment, and chemical processing.

Gate Valve Manufacturer Considerations

On the other hand, gate valves are designed primarily for full flow applications. A gate valve manufacturer often highlights the valve’s ability to provide a straight-line flow with minimal resistance. Unlike ball valves, gate valves are not suitable for throttling purposes, as they can cause turbulence and wear. However, they excel in applications where a complete shut-off is necessary, such as in pipelines and large-scale water systems. The gate mechanism allows for a tight seal, preventing leakage when fully closed.

Conclusion

The choice between ball valve vs gate valve depends on the specific requirements of the application. Ball valves are ideal for quick shut-off and high-pressure scenarios, while gate valves are better suited for applications requiring minimal flow resistance. Manufacturers must carefully consider these factors when selecting the appropriate valve type for their projects, ensuring optimal performance and reliability in their systems.

Post time: Jan-04-2025