Introduction to Ball Valves

Ball valves are indispensable components in industrial piping systems, offering reliable shut-off and flow control for liquids, gases, and slurries. Their simple yet robust design makes them a preferred choice across industries like oil and gas, chemical processing, water treatment, and HVAC. At the heart of their functionality lie critical ball valve parts, each engineered to ensure durability, precision, and leak-free operation. This guide explores the anatomy of ball valves, the role of key components, and why partnering with a trusted Ball Valve Manufacturer—especially a China Ball Valve supplier—can optimize your operations.

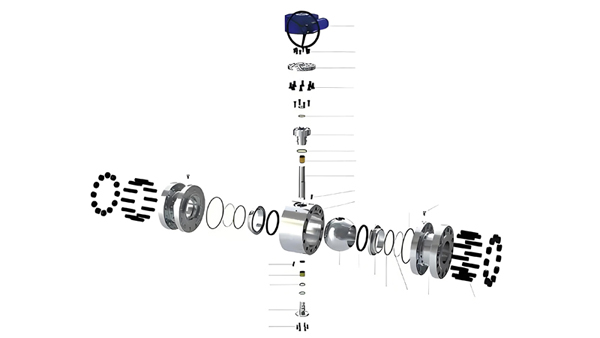

Anatomy of a Ball Valve: Key Components Explained

Understanding the ball valve parts is essential for selecting the right valve and maintaining its performance. Below, we break down the critical components:

1. Ball Valve Body

The valve body is the outer shell that houses all internal components. It’s typically made from durable materials like stainless steel, brass, or carbon steel. For high-corrosion environments, Stainless Steel Ball Valve variants are ideal due to their resistance to rust and chemical degradation. The body design varies between one-piece, two-piece, or three-piece configurations, affecting maintenance ease and cost.

2. Valve Bonnet

The valve bonnet is a cover mounted on the valve body, securing internal parts and ensuring pressure containment. It’s often bolted or threaded to the body for easy access during repairs. In high-pressure applications, forged steel bonnets are common, while China Ball Valve manufacturers may use precision-cast bonnets for cost efficiency without compromising quality.

3. Ball Valve Ball (The Core Component)

The valve ball is a spherical disc with a bore (hole) through its center. Rotating the ball 90 degrees opens or closes the flow path. The ball’s material and surface finish determine its suitability:

- Stainless Steel Ball Valve: Offers superior corrosion resistance for aggressive media.

- Chrome-plated or ceramic-coated balls enhance wear resistance in abrasive applications.

4. Stem

The stem connects the actuator (handle or motor) to the ball, transmitting rotational force. A properly sealed stem prevents leaks. Common designs include:

- Floating Stem: Relies on packing seals.

- Trunnion Stem: Supported by bearings for high-pressure stability.

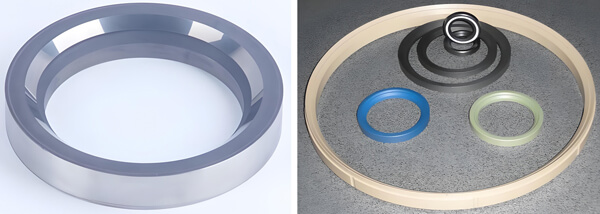

5. Seats

Valve seats create a tight seal between the ball and body. Materials like PTFE (Teflon) or reinforced thermoplastics ensure zero leakage. In Stainless Steel Ball Valve models, metal-seated variants handle extreme temperatures.

6. Actuator

While not part of the valve itself, actuators (manual levers, gears, or automated systems) enable remote or automated control.

Why Ball Valve Design Matters

The efficiency of a ball valve hinges on how well its parts work together:

- Full-Port vs. Reduced-Port: Full-port valves minimize flow restriction, ideal for viscous fluids.

- Fire-Safe Design: Critical for oil and gas applications, using graphite seals that withstand high heat.

- Anti-Static Feature: Prevents spark risks in flammable media by grounding the stem and ball.

Choosing a Reliable Ball Valve Manufacturer

Selecting the right Ball Valve Manufacturer impacts performance, safety, and lifecycle costs. Here’s what to prioritize:

1. Material Quality

Reputable manufacturers use certified materials. For example, China Ball Valve producers often comply with ASTM standards for Stainless Steel Ball Valve components, ensuring AISI 304/316 grade steel.

2. Customization Capabilities

Top suppliers offer tailored solutions:

- Specialized coatings for corrosive or high-temperature environments.

- Unique port sizes or pressure ratings.

3. Certifications

Look for ISO 9001, API 6D, API 607 or CE certifications, which validate manufacturing rigor. Many China Ball Valve exporters meet international standards, making them competitive globally.

4. Cost vs. Value

While China Ball Valve manufacturers often provide cost advantages, ensure this doesn’t come at the expense of quality. Compare warranties, testing protocols, and post-sale support.

The Rise of China as a Ball Valve Manufacturing Hub

China has emerged as a global leader in valve production, combining advanced technology with economies of scale. Key advantages of sourcing from a China Ball Valve supplier include:

- Cost Efficiency: Competitive pricing due to streamlined production and lower labor costs.

- Scalability: Ability to handle bulk orders without lead time delays.

- Innovation: Adoption of CNC machining and robotic welding for precision.

- Export Expertise: Familiarity with international shipping and compliance.

Stainless Steel Ball Valves: When to Choose Them

Stainless Steel Ball Valve units excel in demanding environments:

1. Corrosive Media: Resists acids, alkalis, and saltwater.

2. High-Temperature Applications: Maintains integrity up to 500°F (260°C).

3. Hygienic Requirements: Ideal for food, beverage, and pharmaceutical industries due to non-reactive surfaces.

Maintenance Tips for Ball Valve Parts

Extend valve lifespan with proactive care:

- Lubricate Seals: Use silicone-based grease to prevent seat wear.

- Inspect for Leaks: Test under pressure periodically.

- Replace Worn Parts: Stock critical ball valve parts like seats and stems for quick repairs.

Conclusion

From the valve body to the actuator, every component plays a vital role in a ball valve’s performance. Whether you need a standard Stainless Steel Ball Valve or a custom-engineered solution, partnering with a certified Ball Valve Manufacturer ensures reliability. With their blend of affordability and innovation, China Ball Valve suppliers are increasingly the go-to choice for industries worldwide.

By understanding ball valve parts and their functions, you can make informed decisions that enhance system efficiency, reduce downtime, and lower total ownership costs.

Post time: Apr-15-2025