Comparative analysis of Ball Valve and Globe Valve

Basic introduction to the two types of valves

Ball Valve and Globe Valve are two common valve types in the industrial field. They have significant differences in structure, function and application scenarios.

Main functional features

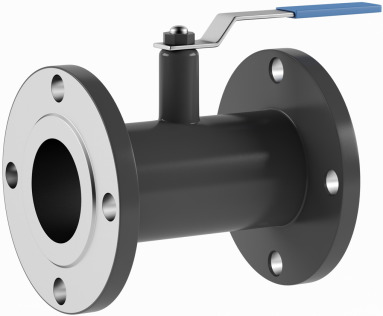

1. Ball Valve

* Simple structure, mainly composed of ball, valve seat, valve stem and handle.

* Easy to operate, the opening and closing action can be completed by rotating the handle or actuator 90 degrees.

* Good sealing performance, metal or soft sealing material is used between the ball and the valve seat, which can achieve reliable sealing effect.

* The fluid resistance is small. When fully open, the ball channel is consistent with the fluid path, reducing fluid resistance.

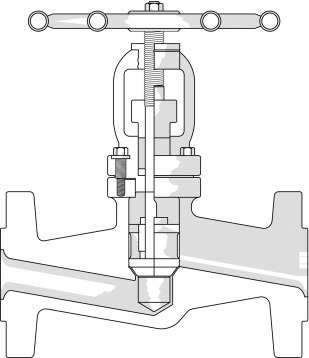

2. Globe Valve

* The structure is relatively complex. There is a valve disc inside the valve body that can move up and down.

* The operation is cumbersome, usually requiring manual rotation of the handwheel or up and down movement of the actuator to achieve opening and closing.

* The sealing performance is better, but it may be more susceptible to media erosion and wear than ball valves.

* The fluid resistance is large, because the valve disc needs to be in close contact with the valve seat when closing, which increases the resistance when the fluid passes.

Applicable scenarios for the two valves

1. Ball Valve

* Widely used in pipeline systems in petroleum, chemical, natural gas, electric power and other industries to cut off, distribute and change the flow direction of the medium.

* Suitable for occasions requiring quick opening and closing, easy operation and low fluid resistance.

2. Globe Valve

* Commonly used in steam pipelines, water supply systems and other occasions where fluid flow needs to be adjusted or cut off.

* Suitable for occasions that require fully open and fully closed operations and require high sealing performance.

Division of user groups

There is no obvious division between the two types of valves in terms of user groups, but they are selected based on specific application scenarios and needs. In situations where fast opening and closing and easy operation are required, users are more likely to choose ball valves; while in situations where flow needs to be adjusted and high sealing performance requirements are required, users are more likely to choose stop valves.

Valve selection suggestions

When selecting valves, the appropriate type should be selected based on specific usage scenarios and needs. Here are some suggestions:

* For occasions that require quick opening and closing, easy operation and low fluid resistance, it is recommended to choose ball valves.

* For occasions where flow rate needs to be adjusted and sealing performance is required, it is recommended to choose a stop valve.

* When selecting valves, factors such as the nature, temperature, and pressure of the medium should also be considered to ensure the reliability and safety of the valve.

Basic operation of valves

1. Ball Valve

* Open: Rotate the handle or actuator 90 degrees counterclockwise to align the ball channel with the fluid path.

* Close: Rotate the handle or actuator 90 degrees clockwise to stagger the ball channel and the fluid path.

2. Globe Valve

* Open: Rotate the handwheel or actuator clockwise to lift the valve disc and separate it from the valve seat.

* Close: Rotate the handwheel or actuator counterclockwise to make the valve disc drop and fit tightly with the valve seat.

Advantages of efficiency and convenience

1. Ball Valve

* Easy and fast operation, reducing operating time and labor costs.

* Good sealing performance, reducing the risk of media leakage.

* Small fluid resistance improves the efficiency of the piping system.

2. Globe Valve

* The adjustment performance is good and can meet the needs of different flow adjustment.

* The sealing performance is reliable and performs well in situations where fluid flow needs to be cut off.

In Summery

there are significant differences between Ball Valve and Globe Valve in terms of structure, functional characteristics, applicable scenarios and operation methods. When selecting valves, the appropriate type should be selected based on specific usage scenarios and needs to ensure the reliability and safety of the valve.

Post time: Nov-19-2024