Are Ball Valves Directional? Understanding Bidirectional vs. Directional Valves

When selecting a ball valve for industrial pipelines, a common question arises: Are ball valves directional The answer depends on the valve type. Ball valves are categorized into bidirectional ball valves and directional ball valves, each designed for specific flow control scenarios. This guide breaks down their differences, applications, and pricing to help you choose the right valve for your needs.

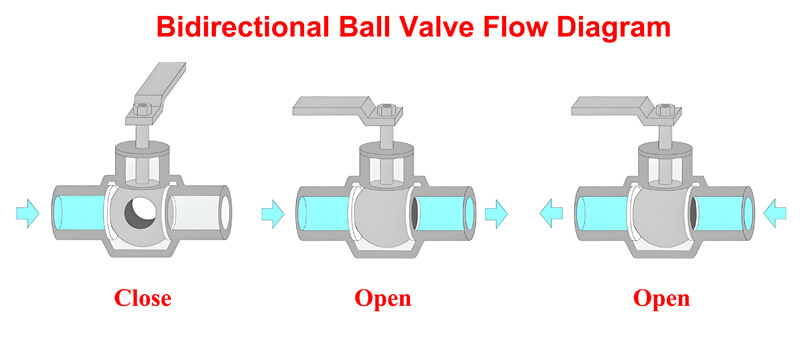

What Is a Bidirectional Ball Valve

A bidirectional ball valve is designed to handle media flow in both forward and reverse directions. Its key features include:

- Double-end sealing design: Sealing surfaces on both ends of the ball ensure tight closure, regardless of flow direction.

- No installation restrictions: Can be installed in any orientation, making it ideal for pipelines requiring reversible flow.

- Durability: Widely used in water supply, heating, and industrial systems due to its robust construction.

Example applications: Oil and gas pipelines, HVAC systems, and chemical processing plants.

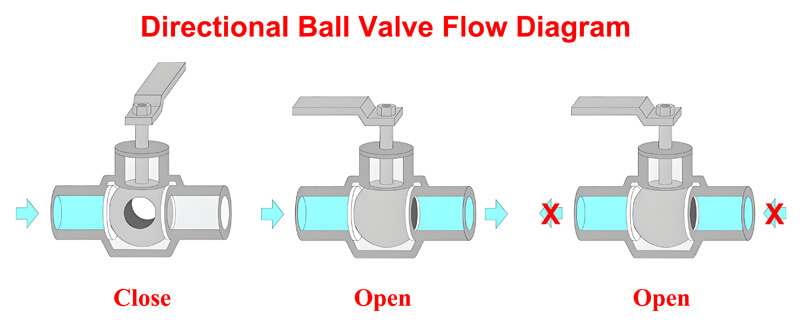

What Is a Directional Ball Valve

A directional ball valve allows media flow in one direction only. Key characteristics include:

- Single-end sealing design: Sealing occurs only on the specified flow direction, marked with an arrow by the ball valve factory.

- Strict installation requirements: Must align with the pipeline’s flow direction to ensure proper sealing.

- Cost-effective: Simpler structure reduces manufacturing costs, making it ideal for unidirectional systems.

Example applications: Petroleum refineries, power plants, and hydraulic systems.

Key Differences Between Bidirectional and Directional Ball Valves

| Factor | Bidirectional Ball Valve | Directional Ball Valve |

| Sealing Design | Double-end sealing | Single-end sealing |

| Flow Direction | Handles bidirectional flow | Restricted to unidirectional flow |

| Installation Flexibility | No direction requirements | Requires alignment with flow arrow |

| Cost | 40% higher due to complex design | Lower manufacturing costs |

| Applications | Water supply, reversible pipelines | Oil, gas, and hydraulic systems |

1. Structural Differences

- Bidirectional valves have two sealing holes (front and rear) for 360° sealing.

- Directional valves feature a single sealing hole, limiting flow to one direction.

2. Fluid Control Flexibility

Bidirectional valves excel in systems requiring reversible flow, while directional valves suit strictly unidirectional pipelines.

3. Sealing Performance

Bidirectional valves maintain tight sealing in both flow directions, whereas directional valves may leak if installed incorrectly.

4. Pricing Factors

Ball valve price varies significantly:

- Bidirectional valves cost ~40% more due to complex machining and materials.

- Directional valves are budget-friendly for simpler systems.

How to Choose the Right Ball Valve

1. Assess Flow Requirements: Determine if your system needs unidirectional or reversible flow.

2. Check Installation Constraints: Ensure directional valves align with pipeline flow arrows.

3. Compare Costs: Balance durability and budget—bidirectional valves offer long-term value for dynamic systems.

For bulk orders, partner with a reputable **ball valve manufacturer** or **ball valve factory** to ensure quality and compliance.

Conclusion

So, are ball valves directional, The answer depends on the type. Bidirectional ball valves provide versatile, reversible flow control, while directional ball valves are cost-effective for one-way systems. Always verify the ball valve flow direction markings during installation to avoid leaks. For competitive ball valve prices and reliable performance, source valves from certified manufacturers.

Need expert advice, Contact trusted ball valve manufacturers, one of the Top Ten Chinese Valve Brands today to find the perfect solution for your industrial needs!

Post time: Mar-16-2025