Understanding the differences between the API 607 and API 608 standards is critical when choosing the right ball valve for your industrial application. These standards govern the performance, safety, and reliability of ball valves, which are essential components in a variety of piping systems. In this article, we’ll explore the key differences between API 607 and API 608, the impact on ball valve pricing, and the role of manufacturers, especially in China, in providing high-quality ball valves.

Understanding API Standards

API, or the American Petroleum Institute, sets standards for the oil and gas industry, including valve specifications. API 607 and API 608 are two important standards that focus on fire safety and general requirements for ball valves, respectively.

API 607: Fire Testing for Soft-Seat Quarter-Turn Valves

The API 607 standard, outlines the fire testing requirements for soft-seat quarter-turn valves, including ball valves. This standard is particularly important for applications that require fire protection, such as the oil and gas industry. Key features of API 607 include:

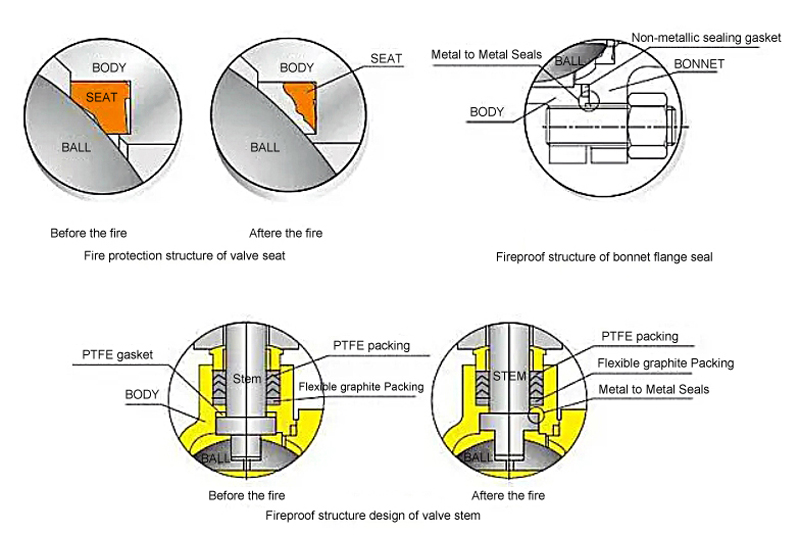

- Fire resistance: Valves that meet API 607 standards are tested to ensure they can withstand high temperatures and prevent leakage in the event of a fire.

- Soft seat design: The standard applies to valves with soft seats, which are typically made of materials such as PTFE or elastomers. These materials have good sealing properties but are easily affected by high temperatures.

- Testing protocols: API 607 specifies rigorous testing protocols to evaluate the performance of valves under fire conditions, ensuring they maintain integrity and functionality.

API 608: Metal-seated ball valves

API 608 focuses on general requirements for metal-seated ball valves. The standard applies to valves designed for higher pressure and temperature applications. Key aspects of API 608 include:

- Metal seat design: Unlike API 607, which covers soft-seated valves, API 608 covers metal-seated valves. These valves are generally more durable and can withstand extreme conditions.

- Performance Standards: API 608 outlines performance standards for leakage, pressure, and temperature ratings, ensuring valves can operate effectively in demanding environments.

- Versatility: Metal-seated ball valves are frequently used in a variety of industries, including chemical processing, power generation, and water treatment, due to their ruggedness and reliability.

Choosing Between API 607 and API 608

When choosing between API 607 and API 608 ball valves, consider the following:

- Application Requirements: If your application involves high temperatures and potential fire hazards, API 607 valves are a better choice. For applications that require resistance to high pressures and temperatures without fire hazards, API 608 valves may be more appropriate.

- Material Considerations: Material selection is critical. Soft-seated valves (API 607) may be more susceptible to damage under extreme conditions, while metal-seated valves (API 608) offer greater durability.

- Cost Impact: In general, API 607 valves may be more expensive due to the additional fire testing and certification required. However, the long-term savings from reduced maintenance and improved safety may justify the higher initial investment.

- Valve Manufacturer Reputation: It is critical to select a reputable manufacturer. Look for a manufacturer that adheres to API standards and has a proven track record of producing high-quality ball valves.

Ball Valve Price

The price of a ball valve can vary greatly based on a number of factors, including:

- Material: The type of material used in the valve construction (e.g., stainless steel, carbon steel, or exotic alloys) can affect the price.

- Size and Specification: Larger valves or valves with specific pressure and temperature ratings are generally more expensive.

- Certification: Valves that meet API 607 or API 608 standards may have a premium because of the rigorous testing and certification process involved.

- Ball Valve Manufacturer: Prices can also vary based on the reputation and location of the manufacturer. China, for example, has become a major player in the ball valve manufacturing industry, offering competitive pricing while maintaining quality.

Role of Chinese Ball Valve Manufacturers

China has become a leading manufacturer in the ball valve sector, producing a wide range of products that meet various international standards, including API 607 and API 608.

Post time: Feb-08-2025