Good User Reputation for Back Pressure Control Valve - Electric actuator ball valve – Newsway

Good User Reputation for Back Pressure Control Valve - Electric actuator ball valve – Newsway Detail:

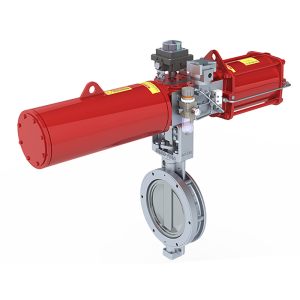

Electric ball valves are important actuators in industrial automation control systems. Electric ball valve is a valve that rotates around the axis of the valve stem based on the movement of the valve disc. The variation of the valve seat opening is directly proportional to the valve disc stroke. Mainly used to cut off or connect media in pipelines, it can also be used for fluid regulation and control, and is a pipeline pressure element in industrial automation process control.

The types of electric ball valves include: floating ball valve, fixed ball valve, track ball valve, V-shaped ball valve, three-way ball valve, stainless steel ball valve, forged steel ball valve, ash discharge ball valve, sulfur resistant ball valve, three-way ball valve, pneumatic ball valve, electric ball valve, sleeve ball valve, welded ball valve, flange ball valve, and threaded ball valve.

Floating Ball: The ball of a ball valve is floating, and under the pressure of the medium, the ball can produce a certain displacement and tightly press on the sealing surface of the outlet end, ensuring the sealing of the outlet end. The floating ball valve has a simple structure and good sealing performance, but the ball bears all the load of the working medium and is transmitted to the outlet sealing ring. Therefore, it is necessary to consider whether the sealing ring material can withstand the working load of the ball medium. When subjected to high pressure impact, the ball may deviate. This structure is generally used for medium and low pressure ball valves.

Fixed ball: The ball of a ball valve is fixed and does not move under pressure. Fixed ball valves are equipped with floating valve seats. When subjected to medium pressure, the valve seat moves, causing the sealing ring to tightly press against the ball to ensure sealing. Usually, bearings are installed on the upper and lower shafts of the ball, with small operating torque, suitable for high-pressure and large-diameter valves. In order to reduce the operating torque of ball valves and increase the reliability of sealing, lubricating oil is used to form a layer of oil film, which enhances sealing performance and reduces operating torque, making it more suitable for high-pressure large-diameter ball valves.

Elastic ball: The ball of a ball valve is elastic. Both the sphere and valve seat sealing ring are made of metal materials, with a high sealing pressure ratio. The pressure of the medium itself cannot meet the sealing requirements, and external forces must be applied. This type of valve is suitable for high-temperature and high-pressure media. An elastic sphere is obtained by opening an elastic groove at the lower end of the inner wall of the sphere. When closing the channel, use the wedge-shaped head of the valve stem to expand the ball and compress the valve seat to achieve sealing. Before rotating the ball, loosen the wedge head, and the ball will return to its original shape, creating a small gap between the ball and the valve seat, which can reduce the friction and operating torque of the sealing surface.

Product detail pictures:

Related Product Guide:

Cooperation

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for Good User Reputation for Back Pressure Control Valve - Electric actuator ball valve – Newsway , The product will supply to all over the world, such as: Lisbon, Slovakia, Belize, Our aim is to help customers realize their goals. We have been making great efforts to achieve this win-win situation and sincerely welcome you to join us. In a word, when you choose us, you choose a perfect life. Welcome to visit our factory and welcome your order! For further inquiries, you should do not hesitate to contact us.

Newsway Valves Materials

NSW valve body and trim material can be offered in Forged type and Casting type. Next to stainless and carbon steel material, we also manufacture valves in special materials such as titanium, nickel alloys, HASTELLOY®*, INCOLOY®, MONEL®, Alloy 20, super-duplex, corrosion resistant alloys and urea grade materials.

Available materials

| Tradename | UNS nr. | Werkstoff nr. | Forging | Casting |

| Carbon steel | K30504 | 1.0402 | A105 | A216 WCB |

| Carbon steel | 1.046 | A105N | ||

| Low Temp Carbon steel | K03011 | 1.0508 | A350 LF2 | A352 LCB |

| High Yield steel | K03014 | A694 F60 | ||

| 3 1/2 Nickel steel | K32025 | 1.5639 | A350 LF3 | A352 LC3 |

| 5 Chrome, 1/2 Moly | K41545 | 1.7362 | A182 F5 | A217 C5 |

| 1 1/4 Chrome, 1/2 Moly | K11572 | 1.7733 | A182 F11 | A217 WC6 |

| K11597 | 1.7335 | |||

| 2 1/4 Chrome, 1/2 Moly | K21590 | 1.738 | A182 F22 | A217 WC9 |

| 9 Chrome, 1 Moly | K90941 | 1.7386 | A182 F9 | A217 CW6 |

| X 12 Chrome, 091 Moly | K91560 | 1.4903 | A182 F91 | A217 C12 |

| 13 Chrome | S41000 | A182 F6A | A351 CA15 | |

| 17-4PH | S17400 | 1.4542 | A564 630 | |

| 254 SMo | S31254 | 1.4547 | A182 F44 | A351 CK3MCuN |

| 304 | S30400 | 1.4301 | A182 F304 | A351 CF8 |

| 304L | S30403 | 1.4306 | A182 F304L | A351 CF3 |

| 310S | S31008 | 1.4845 | A182 F310S | A351 CK20 |

| 316 | S31600 | 1.4401 | A182 F316 | A351 CF8M |

| S31600 | 1.4436 | |||

| 316L | S31603 | 1.4404 | A182 F316L | A351 CF3M |

| 316Ti | S31635 | 1.4571 | A182 F316Ti | |

| 317L | S31703 | 1.4438 | A182 F317L | A351CG8M |

| 321 | S32100 | 1.4541 | A182 F321 | |

| 321H | S32109 | 1.4878 | A182 F321H | |

| 347 | S34700 | 1.455 | A182 F347 | A351 CF8C |

| 347H | S34709 | 1.4961 | A182 F347H | |

| 410 | S41000 | 1.4006 | A182 F410 | |

| 904L | N08904 | 1.4539 | A182 F904L | |

| Carpenter 20 | N08020 | 2.466 | B462 N08020 | A351 CN7M |

| Duplex 4462 | S31803 | 1.4462 | A182 F51 | A890 Gr 4A |

| SAF 2507 | S32750 | 1.4469 | A182 F53 | A890 Gr 6A |

| Zeron 100 | S32760 | 1.4501 | A182 F55 | A351 GR CD3MWCuN |

| Ferralium® 255 | S32550 | 1.4507 | A182 F61 | |

| Nicrofer 5923 hMo | N06059 | 2.4605 | B462 N06059 | |

| Nickel 200 | N02200 | 2.4066 | B564 N02200 | |

| Nickel 201 | N02201 | 2.4068 | B564 N02201 | |

| Monel® 400 | N04400 | 2.436 | B564 N04400 | A494 M35-1 |

| Monel® K500 | N05500 | 2.4375 | B865 N05500 | |

| Incoloy® 800 | N08800 | 1.4876 | B564 N08800 | |

| Incoloy® 800H | N08810 | 1.4958 | B564 N08810 | |

| Incoloy® 800HT | N08811 | 1.4959 | B564 N08811 | |

| Incoloy® 825 | N08825 | 2.4858 | B564 N08825 | |

| Inconel® 600 | N06600 | 2.4816 | B564 N06600 | A494 CY40 |

| Inconel® 625 | N06625 | 2.4856 | B564 N06625 | A494 CW 6MC |

| Hastelloy® B2 | N10665 | 2.4617 | B564 N10665 | A494 N 12MV |

| Hastelloy® B3 | N10675 | 2.46 | B564 N10675 | |

| Hastelloy® C22 | N06022 | 2.4602 | B574 N06022 | A494 CX2MW |

| Hastelloy® C276 | N10276 | 2.4819 | B564 N10276 | |

| Hastelloy® C4 | N06455 | 2.461 | B574 N06455 | |

| Titanium GR. 1 | R50250 | 3.7025 | B381 F1 | B367 C1 |

| Titanium GR. 2 | R50400 | 3.7035 | B381 F2 | B367 C2 |

| Titanium GR. 3 | R50550 | 3.7055 | B381 F3 | B367 C3 |

| Titanium GR. 5 | R56400 | 3.7165 | B381 F5 | B367 C5 |

| Titanium GR. 7 | R52400 | 3.7235 | B381 F7 | B367 C7 |

| Titanium GR. 12 | R53400 | 3.7225 | B381 F12 | B367 C12 |

| Zirconium® 702 | R60702 | B493 R60702 | ||

| Zirconium® 705 | R60705 | B493 R60705 |

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!