Factory wholesale Semi Lug Butterfly Valve - API 609 Butterfly Valve – Newsway

Factory wholesale Semi Lug Butterfly Valve - API 609 Butterfly Valve – Newsway Detail:

API609 Butterfly Valve

Keyworks:api609,butterfly,valve,wafer,flange,lugged,welded,wcb,cf8m,class150, class300

PRODUCT RANGE:

Sizes: NPS 1/2 to NPS80 (DN15 to DN2000)

Pressure Range: class150, class300, class600, class900

MATERIALS:

Casting: (A995 4A, 5A, A216 WCB, A351 CF3, CF8, CF3M, CF8M, A352 LCB, LCC, LC1, WC6, WC9) Monel, Inconel, Hastelloy, C95800, 2205, 2507, 904L

STANDARD

| Design & manufacture | API609, EN593, ISO10631 |

| Face-to-face | API609, ASME B16.10, ISO5752 series13, EN 558 |

| End Connection | -Flange Ends to ASME B16.5, ASME B16.47 Series B |

| -Wafer End to API609, ASME B16.11 | |

| -Lug End to API609, ASME B16.11 | |

| Test & inspection | API 598, EN12266-1, ISO5208 |

| Fire safe design | API 607 |

| Also available per | NACE MR-0175, NACE MR-0103, ISO 15848 |

| Other | PMI, UT, RT, PT, MT |

API609 butterfly valve, as a component used to realize on-off and flow control of pipeline system, has been widely used in many fields such as petroleum, chemical industry, metallurgy, hydropower and so on. It can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil, liquid metal and radioactive media. It is mainly used for cutting off and throttling on the pipeline. The butterfly valve opening and closing part is a disc-shaped butterfly plate, which rotates around its own axis in the valve body to achieve the purpose of opening and closing or adjustment.

API609 butterfly valve is suitable for fresh water, sewage, sea water, salt water, steam, natural gas, food, medicine, oil and other products that require complete sealing, zero gas test leakage, high life expectancy, and working temperature between -10 degrees and 150 degrees. Kind of acid-base and other pipelines.

The soft sealing eccentric butterfly valve is suitable for the two-way opening and closing and adjustment of ventilation and dust removal pipelines, and is widely used in gas pipelines and waterways in metallurgy, light industry, electric power, and petrochemical systems.

The metal-to-metal wire sealing double eccentric butterfly valve is suitable for urban heating, gas, water supply and other gas, oil, acid and alkali pipelines, as a regulating and throttling device.

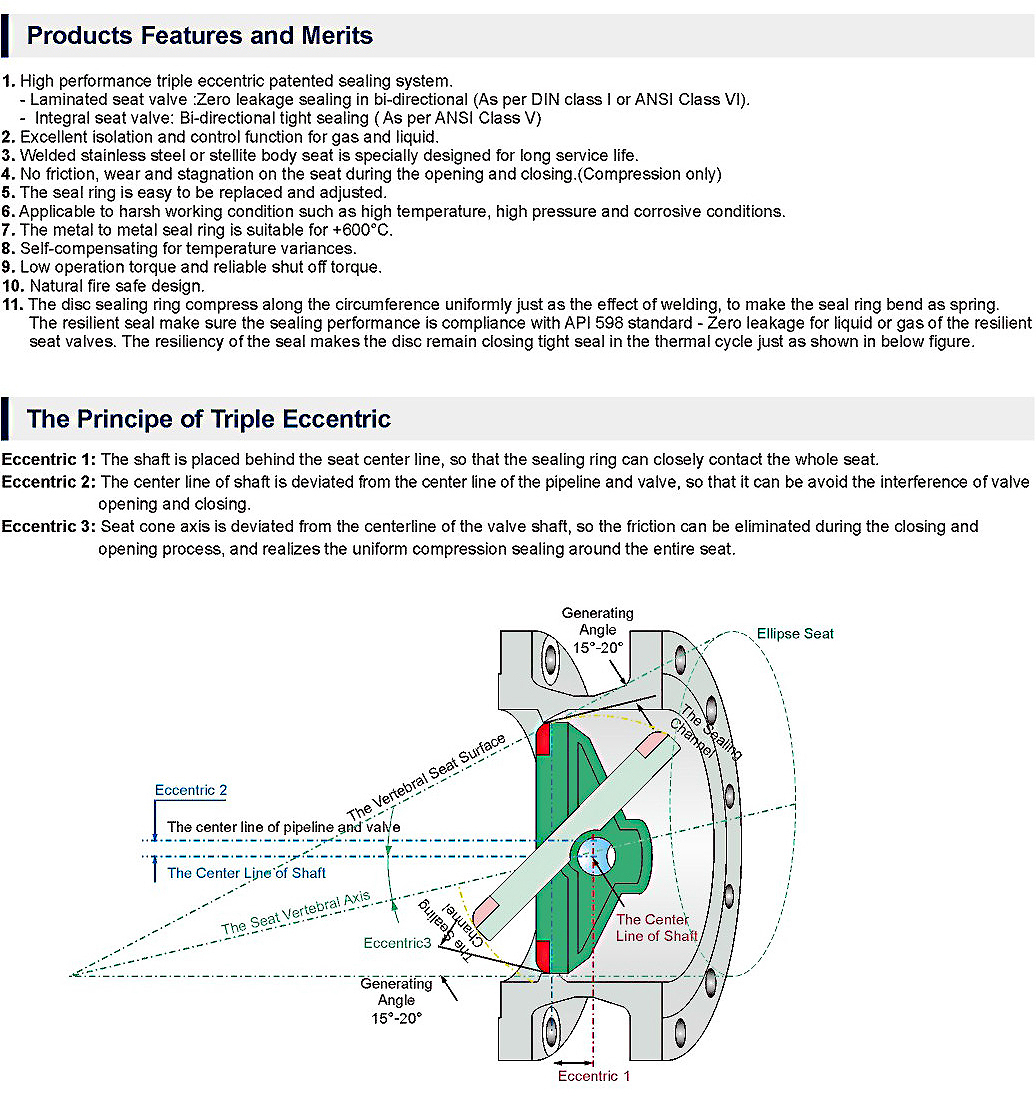

In addition to being used as a large-scale pressure swing adsorption (PSA) gas separation device program control valve, the metal-to-metal seal triple eccentric butterfly valve can also be widely used in petroleum, petrochemical, chemical, metallurgy, electric power and other fields. It is a good gate valve and stop valve. replacement product.

Product detail pictures:

Related Product Guide:

Cooperation

With this motto in mind, we have turn out to be amongst probably the most technologically innovative, cost-efficient, and price-competitive manufacturers for Factory wholesale Semi Lug Butterfly Valve - API 609 Butterfly Valve – Newsway , The product will supply to all over the world, such as: Florida, Brazil, Georgia, Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question items they do not understand. We break down people barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

Newsway Valves Materials

NSW valve body and trim material can be offered in Forged type and Casting type. Next to stainless and carbon steel material, we also manufacture valves in special materials such as titanium, nickel alloys, HASTELLOY®*, INCOLOY®, MONEL®, Alloy 20, super-duplex, corrosion resistant alloys and urea grade materials.

Available materials

| Tradename | UNS nr. | Werkstoff nr. | Forging | Casting |

| Carbon steel | K30504 | 1.0402 | A105 | A216 WCB |

| Carbon steel | 1.046 | A105N | ||

| Low Temp Carbon steel | K03011 | 1.0508 | A350 LF2 | A352 LCB |

| High Yield steel | K03014 | A694 F60 | ||

| 3 1/2 Nickel steel | K32025 | 1.5639 | A350 LF3 | A352 LC3 |

| 5 Chrome, 1/2 Moly | K41545 | 1.7362 | A182 F5 | A217 C5 |

| 1 1/4 Chrome, 1/2 Moly | K11572 | 1.7733 | A182 F11 | A217 WC6 |

| K11597 | 1.7335 | |||

| 2 1/4 Chrome, 1/2 Moly | K21590 | 1.738 | A182 F22 | A217 WC9 |

| 9 Chrome, 1 Moly | K90941 | 1.7386 | A182 F9 | A217 CW6 |

| X 12 Chrome, 091 Moly | K91560 | 1.4903 | A182 F91 | A217 C12 |

| 13 Chrome | S41000 | A182 F6A | A351 CA15 | |

| 17-4PH | S17400 | 1.4542 | A564 630 | |

| 254 SMo | S31254 | 1.4547 | A182 F44 | A351 CK3MCuN |

| 304 | S30400 | 1.4301 | A182 F304 | A351 CF8 |

| 304L | S30403 | 1.4306 | A182 F304L | A351 CF3 |

| 310S | S31008 | 1.4845 | A182 F310S | A351 CK20 |

| 316 | S31600 | 1.4401 | A182 F316 | A351 CF8M |

| S31600 | 1.4436 | |||

| 316L | S31603 | 1.4404 | A182 F316L | A351 CF3M |

| 316Ti | S31635 | 1.4571 | A182 F316Ti | |

| 317L | S31703 | 1.4438 | A182 F317L | A351CG8M |

| 321 | S32100 | 1.4541 | A182 F321 | |

| 321H | S32109 | 1.4878 | A182 F321H | |

| 347 | S34700 | 1.455 | A182 F347 | A351 CF8C |

| 347H | S34709 | 1.4961 | A182 F347H | |

| 410 | S41000 | 1.4006 | A182 F410 | |

| 904L | N08904 | 1.4539 | A182 F904L | |

| Carpenter 20 | N08020 | 2.466 | B462 N08020 | A351 CN7M |

| Duplex 4462 | S31803 | 1.4462 | A182 F51 | A890 Gr 4A |

| SAF 2507 | S32750 | 1.4469 | A182 F53 | A890 Gr 6A |

| Zeron 100 | S32760 | 1.4501 | A182 F55 | A351 GR CD3MWCuN |

| Ferralium® 255 | S32550 | 1.4507 | A182 F61 | |

| Nicrofer 5923 hMo | N06059 | 2.4605 | B462 N06059 | |

| Nickel 200 | N02200 | 2.4066 | B564 N02200 | |

| Nickel 201 | N02201 | 2.4068 | B564 N02201 | |

| Monel® 400 | N04400 | 2.436 | B564 N04400 | A494 M35-1 |

| Monel® K500 | N05500 | 2.4375 | B865 N05500 | |

| Incoloy® 800 | N08800 | 1.4876 | B564 N08800 | |

| Incoloy® 800H | N08810 | 1.4958 | B564 N08810 | |

| Incoloy® 800HT | N08811 | 1.4959 | B564 N08811 | |

| Incoloy® 825 | N08825 | 2.4858 | B564 N08825 | |

| Inconel® 600 | N06600 | 2.4816 | B564 N06600 | A494 CY40 |

| Inconel® 625 | N06625 | 2.4856 | B564 N06625 | A494 CW 6MC |

| Hastelloy® B2 | N10665 | 2.4617 | B564 N10665 | A494 N 12MV |

| Hastelloy® B3 | N10675 | 2.46 | B564 N10675 | |

| Hastelloy® C22 | N06022 | 2.4602 | B574 N06022 | A494 CX2MW |

| Hastelloy® C276 | N10276 | 2.4819 | B564 N10276 | |

| Hastelloy® C4 | N06455 | 2.461 | B574 N06455 | |

| Titanium GR. 1 | R50250 | 3.7025 | B381 F1 | B367 C1 |

| Titanium GR. 2 | R50400 | 3.7035 | B381 F2 | B367 C2 |

| Titanium GR. 3 | R50550 | 3.7055 | B381 F3 | B367 C3 |

| Titanium GR. 5 | R56400 | 3.7165 | B381 F5 | B367 C5 |

| Titanium GR. 7 | R52400 | 3.7235 | B381 F7 | B367 C7 |

| Titanium GR. 12 | R53400 | 3.7225 | B381 F12 | B367 C12 |

| Zirconium® 702 | R60702 | B493 R60702 | ||

| Zirconium® 705 | R60705 | B493 R60705 |

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!