2020 High quality Sleeved Plug Valve - DBB Plug Valve – Newsway

2020 High quality Sleeved Plug Valve - DBB Plug Valve – Newsway Detail:

DBB Plug Valve

PRODUCT RANGE:

Sizes: NPS 2 to NPS 42

Pressure Range: Class 150 to Class 600

Flange Connection: RF, FF, RTJ

MATERIALS:

Casting: (A216 WCB, A351 CF3, CF8, CF3M, CF8M, A995 4A, 5A, A352 LCB, LCC, LC2) Monel, Inconel, Hastelloy,UB6

STANDARD

| Design & manufacture | API 6D, API 599 |

| Face-to-face | ASME B16.10 |

| End Connection | ASME B16.5, ASME B16.47, MSS SP-44 (NPS 22 Only) |

| Test & inspection | API 6D, API 598 |

| Fire safe design | API 6FA |

| Also available per | NACE MR-0175, NACE MR-0103 |

| Other | PMI, UT, RT, PT, MT |

| Fugitive emissions | Complies to ISO 15848-1 |

Design Features:

1.Body structure

The valve body of our DBB Plug Valve includes valve body, valve core, valve disc (embedded in main sealing ring), end cover, chassis, packing and other main components. The valve core and disc are the core of the valve body part. The valve core is fixed in the valve body with the upper and lower trunnions, the flow channel opening is in the middle, and the two sides are wedge-shaped surfaces. The wedge face mill has dovetail guide rails that are attached to two discs on both sides. The disc is the main sealing element and has a cylindrical surface. Accuracy of Class B hard seal can be achieved. The cylindrical surface is milled with a groove circle, and the main sealing ring is permanently embedded with fluorine rubber or nitrile rubber, etc. by molding and vulcanization, which plays the role of hard sealing and soft sealing when the valve is closed.

2.Manipulator structure

The manipulator is mainly composed of signs, hand wheel, spindle bushings, ball pins, brackets and other components, which are fixed on the end cover and connected with the spool rod by connecting pins. The manipulator part is the actuator of the action. Close the valve from the open position, turn the hand wheel clockwise, the valve core rotates 90° first, and drives the valve disc to rotate to the valve body flow channel position. Then the valve core moves down in a straight line, driving the valve disc to expand radially and approach the inner wall of the valve until the soft seal is pressed into the groove, so that the surface of the valve disc is in contact with the inner wall of the valve.

3. Close the process.

Open the valve from the closed position, turn the handwheel counterclockwise, the valve core first moves straight up, and then rotates 90° after reaching a certain position, so that the valve is in a conducting state.

4. DBB or DIB Function

The DBB Plug Valve (double block and bleed plug valve) also named GENERAL VALVE, Twin Seal plug valve. this constant wear by using two seating slips mounted independently on a tapered plug by dovetails, which mechanically retract from the seating surface prior to rotating. This provides a bubble-tight verifiable dual seal without seal abrasion.

If you need more information about DBB Plug valve or DIB Plug valve, please contact our market department. Tel.: 0086-577-67915979, Email: sales@nswvalve.com

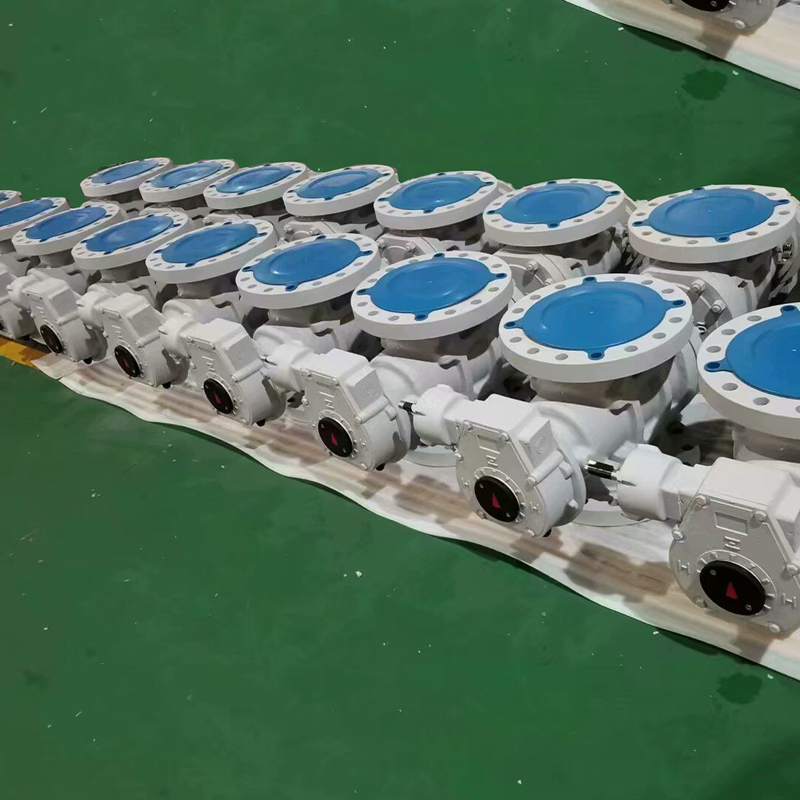

Product detail pictures:

Related Product Guide:

Cooperation

"Control the standard by the details, show the power by quality". Our firm has strived to establish a extremely efficient and stable employees crew and explored an effective excellent command method for 2020 High quality Sleeved Plug Valve - DBB Plug Valve – Newsway , The product will supply to all over the world, such as: Surabaya, Cambodia, Brunei, Our focus on product quality, innovation, technology and customer service has made us one of undisputed leaders worldwide in the field. Bearing the concept of "Quality First, Customer Paramount, Sincerity and Innovation" in our mind, We have achieved great progress in the past years. Clients are welcomed to buy our standard products, or send us requests. You will be impressed by our quality and price. Please contact us now!

Materials of Newsway Valve Manufacturer Products

The China Valve Manufacturer from China, its valves body and trim material can be offered in Forged type and Casting type. Next to Stainless Steel and Carbon Steel material, we also manufacture valves in special materials such as titanium, nickel alloys, HASTELLOY®*, INCOLOY®, MONEL®, Alloy 20, super-duplex, corrosion resistant alloys and urea grade materials.

Available Valve Materials

| Tradename | UNS nr. | Werkstoff nr. | Forging | Casting |

| Carbon steel | K30504 | 1.0402 | A105 | A216 WCB |

| Carbon steel | 1.046 | A105N | ||

| Low Temp Carbon steel | K03011 | 1.0508 | A350 LF2 | A352 LCB |

| High Yield steel | K03014 | A694 F60 | ||

| 3 1/2 Nickel steel | K32025 | 1.5639 | A350 LF3 | A352 LC3 |

| 5 Chrome, 1/2 Moly | K41545 | 1.7362 | A182 F5 | A217 C5 |

| 1 1/4 Chrome, 1/2 Moly | K11572 | 1.7733 | A182 F11 | A217 WC6 |

| K11597 | 1.7335 | |||

| 2 1/4 Chrome, 1/2 Moly | K21590 | 1.738 | A182 F22 | A217 WC9 |

| 9 Chrome, 1 Moly | K90941 | 1.7386 | A182 F9 | A217 CW6 |

| X 12 Chrome, 091 Moly | K91560 | 1.4903 | A182 F91 | A217 C12 |

| 13 Chrome | S41000 | A182 F6A | A351 CA15 | |

| 17-4PH | S17400 | 1.4542 | A564 630 | |

| 254 SMo | S31254 | 1.4547 | A182 F44 | A351 CK3MCuN |

| 304 | S30400 | 1.4301 | A182 F304 | A351 CF8 |

| 304L | S30403 | 1.4306 | A182 F304L | A351 CF3 |

| 310S | S31008 | 1.4845 | A182 F310S | A351 CK20 |

| 316 | S31600 | 1.4401 | A182 F316 | A351 CF8M |

| S31600 | 1.4436 | |||

| 316L | S31603 | 1.4404 | A182 F316L | A351 CF3M |

| 316Ti | S31635 | 1.4571 | A182 F316Ti | |

| 317L | S31703 | 1.4438 | A182 F317L | A351CG8M |

| 321 | S32100 | 1.4541 | A182 F321 | |

| 321H | S32109 | 1.4878 | A182 F321H | |

| 347 | S34700 | 1.455 | A182 F347 | A351 CF8C |

| 347H | S34709 | 1.4961 | A182 F347H | |

| 410 | S41000 | 1.4006 | A182 F410 | |

| 904L | N08904 | 1.4539 | A182 F904L | |

| Carpenter 20 | N08020 | 2.466 | B462 N08020 | A351 CN7M |

| Duplex 4462 | S31803 | 1.4462 | A182 F51 | A890 Gr 4A |

| SAF 2507 | S32750 | 1.4469 | A182 F53 | A890 Gr 6A |

| Zeron 100 | S32760 | 1.4501 | A182 F55 | A351 GR CD3MWCuN |

| Ferralium® 255 | S32550 | 1.4507 | A182 F61 | |

| Nicrofer 5923 hMo | N06059 | 2.4605 | B462 N06059 | |

| Nickel 200 | N02200 | 2.4066 | B564 N02200 | |

| Nickel 201 | N02201 | 2.4068 | B564 N02201 | |

| Monel® 400 | N04400 | 2.436 | B564 N04400 | A494 M35-1 |

| Monel® K500 | N05500 | 2.4375 | B865 N05500 | |

| Incoloy® 800 | N08800 | 1.4876 | B564 N08800 | |

| Incoloy® 800H | N08810 | 1.4958 | B564 N08810 | |

| Incoloy® 800HT | N08811 | 1.4959 | B564 N08811 | |

| Incoloy® 825 | N08825 | 2.4858 | B564 N08825 | |

| Inconel® 600 | N06600 | 2.4816 | B564 N06600 | A494 CY40 |

| Inconel® 625 | N06625 | 2.4856 | B564 N06625 | A494 CW 6MC |

| Hastelloy® B2 | N10665 | 2.4617 | B564 N10665 | A494 N 12MV |

| Hastelloy® B3 | N10675 | 2.46 | B564 N10675 | |

| Hastelloy® C22 | N06022 | 2.4602 | B574 N06022 | A494 CX2MW |

| Hastelloy® C276 | N10276 | 2.4819 | B564 N10276 | |

| Hastelloy® C4 | N06455 | 2.461 | B574 N06455 | |

| Titanium GR. 1 | R50250 | 3.7025 | B381 F1 | B367 C1 |

| Titanium GR. 2 | R50400 | 3.7035 | B381 F2 | B367 C2 |

| Titanium GR. 3 | R50550 | 3.7055 | B381 F3 | B367 C3 |

| Titanium GR. 5 | R56400 | 3.7165 | B381 F5 | B367 C5 |

| Titanium GR. 7 | R52400 | 3.7235 | B381 F7 | B367 C7 |

| Titanium GR. 12 | R53400 | 3.7225 | B381 F12 | B367 C12 |

| Zirconium® 702 | R60702 | B493 R60702 | ||

| Zirconium® 705 | R60705 | B493 R60705 |

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.